在石油化工厂,压缩机站是关键任务,但往往需要耗费大量时间来建造。 模块化撬装压缩机 提供了一种变革性的解决方案:预先组装、出厂前经过测试的设备,可显著减少现场工作、进度风险和安装成本。

1.异地制造 = 更快部署

模块化压缩机撬装完全在受控工厂条件下建造,80-90% 全部运抵现场,大部分焊接、管道、控制面板和测试工作都已提前完成。这种方法避免了天气延误,最大限度地减少了土建工程的干扰,并能 平行结构大幅压缩项目时间 .

2.质量稳定,风险较低

工厂制造的模块经过严格的质量保证,包括 FAT(工厂验收测试)以确保在发货前可靠运行。这可避免现场施工错误,提高 API/ASME 规范的合规性,并增强整个系统的完整性 .

3.降低资本支出和安装成本

模块化滑橇最大程度地减少了现场劳动力、脚手架和现场支持,从而实现 降低劳动力和民事成本减少现有业务的停机时间

4.增强灵活性和可扩展性

随着工厂需求的变化,可随时将更多压缩机撬装集成到现有系统中。撬装压缩机可提供 即插即用可扩展性因此,这些设备是分阶段扩建或临时需求的理想选择。如果需要,还可以重新安置或重新使用,延长资产寿命 .

5.更安全、更可控的装配环境

工厂车间遵循严格的安全规范--高架起重机、受控焊接实验室和标准化程序。这些 减少现场安全事故特别是在拥堵的石化厂中 .

撬装与棒装压缩系统的比较

| 特点 | 粘贴式系统 | 撬装式压缩机 |

|---|---|---|

| 安装时间 | 数月的现场工作 | 即插即用设置的周数 |

| 质量保证 | 多变且受天气影响 | 工厂测试和认证 |

| 土木与工地工程 | 广泛的基础设施 | 最少的连接和基础 |

| 可扩展性 | 复杂的扩展 | 可通过模块化附加组件轻松扩展 |

| 安全性和可靠性 | 较高的实地风险 | 车间建设更安全,事故更少 |

石化项目中的应用

-

注气站

-

用于原料管线的增压压缩

-

真空蒸馏装置的再压缩

-

氢气、液化石油气、一氧化碳回收系统

所有设备都采用模块化压缩机撬装,从而简化了调试工作,最大限度地减少了设备中断时间。

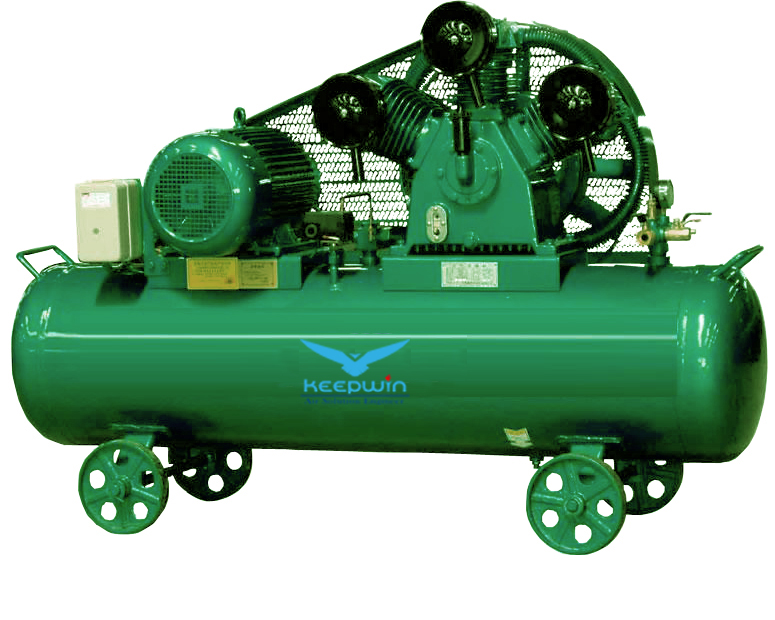

为什么 KEEPWIN 居于领先地位

KEEPWIN 设计的全集成式压缩机撬装系统配有

-

螺杆式、往复式或隔膜式压缩机

-

仪表和控制面板

-

过滤器、冷却器、阀门、脉动阻尼器

-

预接线和面板 PLC/SCADA 测试

我们的机型提供即插即用的交钥匙系统,专为快速启动、高效和石化级安全而设计。

结论

在石油化工工程中,时间、质量和灵活性是不容讨价还价的。 模块化撬装压缩机 KEEPWIN的压缩机撬可全方位降低资本支出、加快进度并提高安全性。有了 KEEPWIN 为客户量身定做的压缩机撬装设备,工厂可以快速交付、简化扩建,并确保合规、高性能的运营。