- 电子邮件:keepwin@keep-win.com

- 热线电话 : +86 13910684359

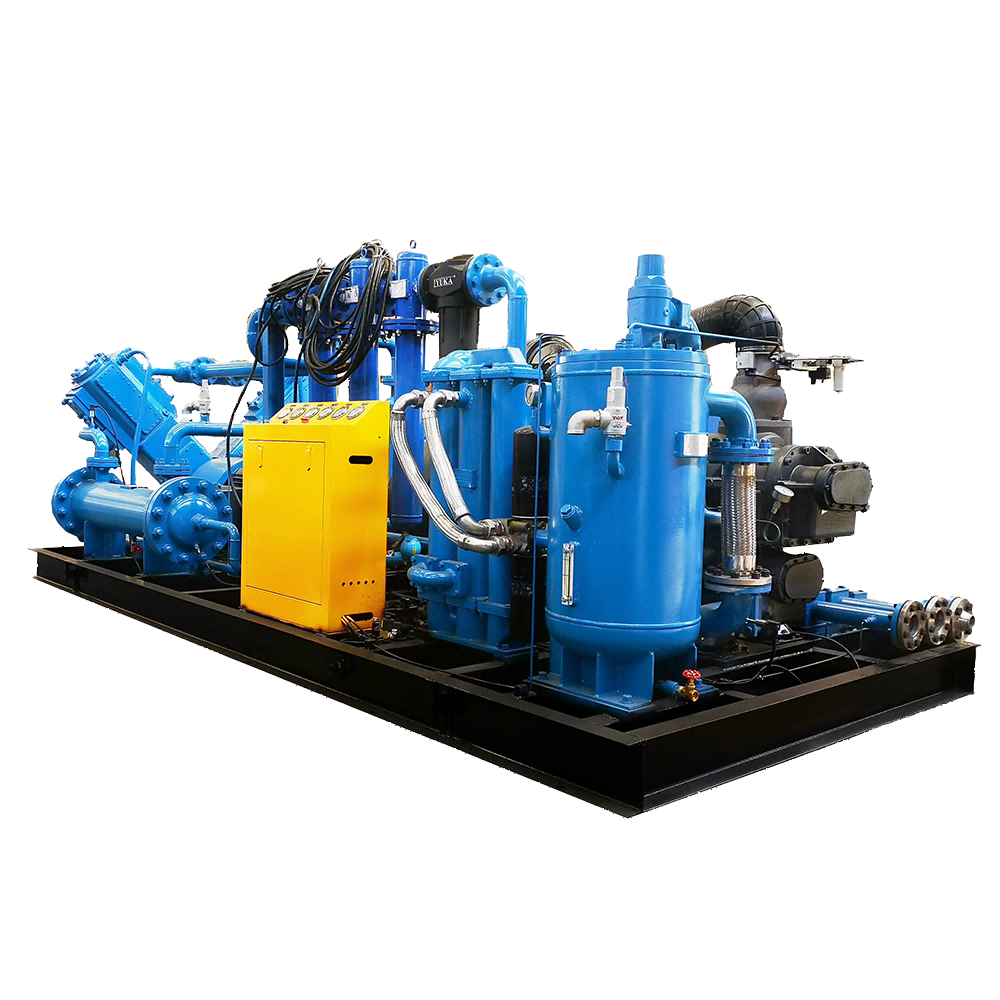

该压缩机融合了螺杆和活塞技术,性能多样,可满足各种工业需求。它以能够处理各种流量和压力而著称。

该压缩机融合了螺杆和活塞技术,性能多样,可满足各种工业需求。它以能够处理各种流量和压力而著称。

螺杆活塞压缩机,也称为混合压缩机,结合了螺杆压缩机和活塞压缩机的优点。这种独特的设计带来了广泛的应用范围:

1.天然气压缩:

2.工业气体压缩:

3.制冷与空调

4.其他应用:

螺杆活塞式压缩机的工作原理可分为两个主要阶段:螺杆压缩阶段和活塞压缩阶段。

组件

螺杆活塞式压缩机主要由以下部件组成:

工作特性:

Keepwin 可根据流量/纯度/压力、使用环境、主要用途和客户的特殊要求,以具有竞争力的价格提供独立的解决方案。我们的压缩机增压器采用优质材料制成,并经过全面测试,以确保最佳质量。

全世界的制造商都将 Keepwin 作为顶级压缩机制造商,这是有原因的。从工业制造到能源工业,以及介于两者之间的所有领域,我们的系统 20 多年来一直深受 100 多个国家和地区的信赖。

准备好将您的行业提升到新的高度了吗?继续阅读,了解 Keepwin 为何是气体压缩机的不二之选

按照 ISO9001 ISO14001 标准生产。获得 CE TUV ASME 等证书

经验丰富的工程师,拥有 39 年丰富的压缩机设计专业知识

从设计到安装,我们的压缩机解决方案可为您节省时间和精力。

从近 22 年的经验中获益。

不要只听我们的一面之词:Keepwin 压缩机的卓越品质。世界各地的制造商都称赞 Keepwin 压缩机具有卓越的精度、耐用性、功率、速度和质量。请亲自了解 Keepwin 为什么是压缩机解决方案的可靠选择。

"我们十年前购买的 Keepwin 1500Nm³/h、500bar 膜氮气增压机在运行十年后仍然表现稳定。除了定期更换易损件外,设备很少出现故障,大大降低了我们的维护成本"。

阿里-德博拉 服务工程师

"你们压缩机的质量和耐用性都非常出色。自安装以来,我们经历了最少的停机时间,压缩机的性能始终保持在最佳水平"。

穆罕默德 工地工程师

透明度是 KEEPWIN 的核心价值。 为了帮助您做出明智的决定,我们汇编了一份有关我们压缩机系统的常见问题清单。

成立于 2002 年、 奇普瑞 是一家历史悠久的活塞和隔膜压缩机制造商。我们在苏州和蚌埠设有生产基地,致力于提供可靠、节能和高品质的压缩解决方案。我们的目标是通过卓越的服务和创新的产品超越客户的期望。

KEEPWIN 提供各种类型的压缩机,包括螺杆式、螺杆活塞组合式、往复活塞式和无油隔膜式压缩机。我们先进的工程设计能力使我们能够为石油和天然气、化工、食品和氢能领域的苛刻应用提供量身定制的解决方案。

Keepwin 在设计和制造能够处理苛刻应用的压缩机方面有着良好的记录。我们的压缩机输出功率高达 3000 kW,排气压力高达 3200 bar,流量高达 60000 Nm³/h,适用于包括空气、氢气、氮气和腐蚀性气体在内的各种气体。

我们的经销商遍布全球。我们的代理商是我们团队的重要组成部分,为客户提供全方位的服务。事实上,您可以从我们的专业代理商那里获得我们的全部产品和服务。 联系我们 我们将为您推荐附近的经销商。

我们设计和制造的压缩机符合 API 618 标准的严格要求。API 618 活塞式压缩机在炼油厂、天然气和氢气应用中具有高可靠性和低维护率的特点。

作为您的一站式气体压缩机解决方案供应商,Keepwin 提供从制造、安装到全面培训的端到端服务。这可确保您获得最大的投资效益,而不会出现任何延误。

立即获得最精确的压缩机设计。

*我们尊重您的隐私。提交后,我们的 Keepwin 专家将尽快与您联系。

我们的压缩机效率极高,可以为一座小城市供电......或者至少可以为一个真正的大冰箱供电。想亲眼看看吗?今天就获取报价!

Keepwin 总是及时响应客户的需求,并为解决问题付出额外的努力。

我们诚挚地邀请您参观我们的办公室和工厂。我们期待为您服务。

我们将安排专业工程师设计出适合您需求的解决方案。

*我们尊重您的隐私。提交后,我们的 Keepwin 专家将尽快与您联系。

"三年前,当我们选择Keepwin提供氦膜压缩机并签订了为期100天的合同时,他们的表现超出了所有预期。Keepwin 提前完成了生产计划、工程图纸和设备调试,展示了他们非凡的专业精神和效率"。

Александр Сергеевич 采购经理