小型无油活塞压缩机

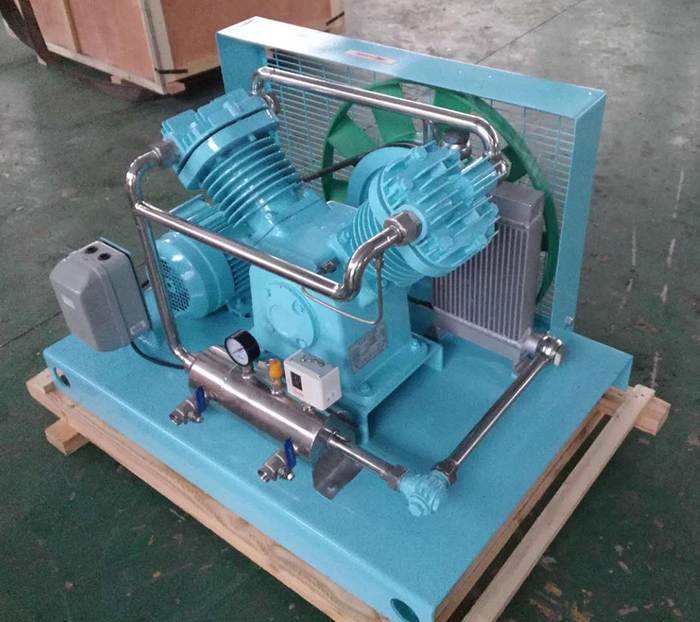

Experience the benefits of our oil-free piston compressors: reliable, efficient, and quiet operation. Ideal for applications requiring the highest levels of air purity, our compressors are designed to meet your most demanding needs.

Experience the benefits of our oil-free piston compressors: reliable, efficient, and quiet operation. Ideal for applications requiring the highest levels of air purity, our compressors are designed to meet your most demanding needs.

Experience the benefits of our oil-free piston compressors: reliable, efficient, and quiet operation. Ideal for applications requiring the highest levels of air purity, our compressors are designed to meet your most demanding needs.

1. Cylinder Filling:

2. Medical Industry:

3. Food and Beverage Industry:

4. Electronics Industry:

5. Laboratories and Research:

Characteristics of Oil-Free Piston Compressors:

Due to their ability to provide high-quality compressed air, oil-free piston compressors offer significant advantages in cylinder filling and other applications with strict gas purity requirements.

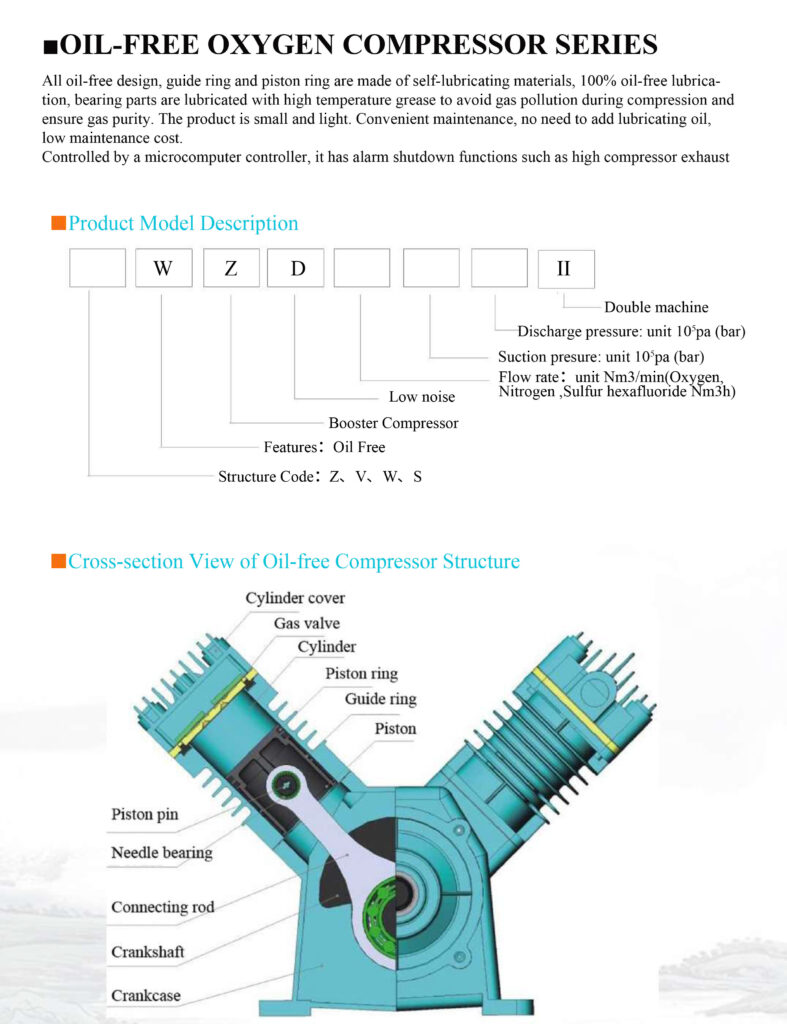

Oil-free piston compressors are designed to deliver clean, contaminant-free compressed air, making them ideal for applications where air purity is paramount. Here’s a breakdown pressors operate on the principle of reciprocating motion to compress air without the need for oil lubrication within the compression chamber. This is achieved through the use of materials with low friction coefficients and specialized sealing techniques. The process involves the following stages:

Component Breakdown:

Oil-free piston compressors consist of several key components:

Experience Unmatched Reliability with Our Compressors: Engineered for Excellence

When it comes to your critical operations, you need a compressor you can depend on. That’s why we’ve engineered our compressors with a relentless focus on quality, durability, and performance.

Superior Material Selection:

Precision Manufacturing:

Rigorous Quality Control:

Comprehensive Pre-Shipment Testing:

Unwavering After-Sales Support:

Exceptional Service:

Invest in a compressor that delivers unmatched reliability and performance. Choose our compressors and experience the difference.

Keepwin 可根据流量/纯度/压力、使用环境、主要用途和客户的特殊要求,以具有竞争力的价格提供独立的解决方案。我们的压缩机增压器采用优质材料制成,并经过全面测试,以确保最佳质量。

全世界的制造商都将 Keepwin 作为顶级压缩机制造商,这是有原因的。从工业制造到能源工业,以及介于两者之间的所有领域,我们的系统 20 多年来一直深受 100 多个国家和地区的信赖。

准备好将您的行业提升到新的高度了吗?继续阅读,了解 Keepwin 为何是气体压缩机的不二之选

按照 ISO9001 ISO14001 标准生产。获得 CE TUV ASMI 等证书

经验丰富的工程师,拥有 39 年丰富的压缩机设计专业知识

从设计到安装,我们的压缩机解决方案可为您节省时间和精力。

从近 22 年的经验中获益。

不要只听我们的一面之词:Keepwin 压缩机的卓越品质。世界各地的制造商都称赞 Keepwin 压缩机具有卓越的精度、耐用性、功率、速度和质量。请亲自了解 Keepwin 为什么是压缩机解决方案的可靠选择。

透明度是 KEEPWIN 的核心价值。 为了帮助您做出明智的决定,我们汇编了一份有关我们压缩机系统的常见问题清单。

成立于 2002 年、 奇普瑞 是一家历史悠久的活塞和隔膜压缩机制造商。我们在苏州和蚌埠设有生产基地,致力于提供可靠、节能和高品质的压缩解决方案。我们的目标是通过卓越的服务和创新的产品超越客户的期望。

KEEPWIN 提供各种类型的压缩机,包括螺杆式、螺杆活塞组合式、往复活塞式和无油隔膜式压缩机。我们先进的工程设计能力使我们能够为石油和天然气、化工、食品和氢能领域的苛刻应用提供量身定制的解决方案。

Keepwin 在设计和制造能够处理苛刻应用的压缩机方面有着良好的记录。我们的压缩机输出功率高达 3000 kW,排气压力高达 3200 bar,流量高达 60000 Nm³/h,适用于包括空气、氢气、氮气和腐蚀性气体在内的各种气体。

我们的经销商遍布全球。我们的代理商是我们团队的重要组成部分,为客户提供全方位的服务。事实上,您可以从我们的专业代理商那里获得我们的全部产品和服务。 联系我们 我们将为您推荐附近的经销商。

我们设计和制造的压缩机符合 API 618 标准的严格要求。API 618 活塞式压缩机在炼油厂、天然气和氢气应用中具有高可靠性和低维护率的特点。

作为您的一站式气体压缩机解决方案供应商,Keepwin 提供从制造、安装到全面培训的端到端服务。这可确保您获得最大的投资效益,而不会出现任何延误。

立即获得最精确的压缩机设计。

*我们尊重您的隐私。提交后,我们的 Keepwin 专家将尽快与您联系。

我们的压缩机效率极高,可以为一座小城市供电......或者至少可以为一个真正的大冰箱供电。想亲眼看看吗?今天就获取报价!

Keepwin 总是及时响应客户的需求,并为解决问题付出额外的努力。

我们诚挚地邀请您参观我们的办公室和工厂。我们期待为您服务。

开始与我们的专业工程师交流

*我们尊重您的隐私。提交后,我们的 Keepwin 专家将尽快与您联系。