氢气压缩机

Hydrogen gas is a colorless, odorless, tasteless, flammable gas that is the lightest element on the periodic table. It has a wide range of applications due to its unique properties, including high energy density and clean combustion.

Hydrogen gas compressors are essential equipment used to increase the pressure of hydrogen gas. They find applications in various industries, such as:

- Fuel cell electric vehicles

- Chemical production

- Aerospace

- Electronics

Keepwin Diaphragm Hydrogen Compressor: Powering the Future of Hydrogen Fueling

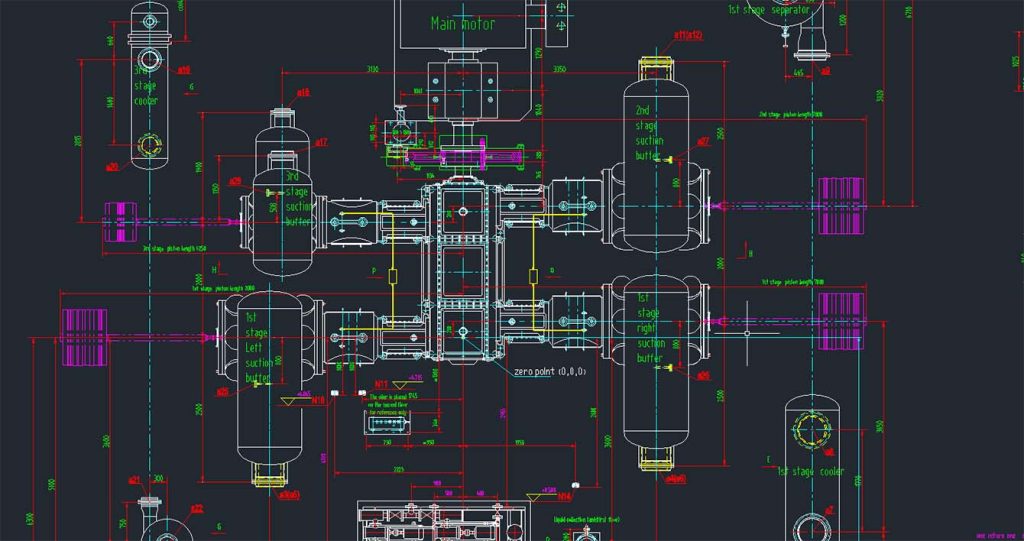

- Model: GD-500/25-400

- Type: D type Two stages Double action Water cooled Oil-Free

- Capacity: 500Nm3/h

- Suction Pressure: 25bar

- Discharge pressure: 400bar

- Speed: 420r/min

- Water consumption: 10t/h

- Motor power: 110Kw

- Motor: Y Series Asynchronism High efficient DIICT4 Explosion-proof

- Dimension: 4300*3000*2000

- Weight: 14700kg

Application of Hydrogen Compressors in Hydrogen Refueling Stations

Hydrogen compressors are essential components of hydrogen refueling stations. Their primary function is to compress low-pressure hydrogen gas to high pressure to meet the fueling demands of hydrogen fuel cell vehicles.

Working Principle Hydrogen compressors convert mechanical energy into the compression of hydrogen gas. When hydrogen enters the compression chamber, a piston or rotor compresses the gas, reducing its volume and increasing its pressure. Through multiple stages of compression, the hydrogen reaches the required pressure for refueling stations, typically 20-90 MPa.

What’s the Hydrogen Refueling Stations ?

- Hydrogen Storage: High-pressure hydrogen is stored in storage tanks to meet the continuous fueling needs of vehicles.

- Hydrogen Fueling: High-pressure hydrogen is dispensed into a vehicle’s hydrogen fuel cell system through a fueling dispenser.

- Ensuring Hydrogen Purity: Hydrogen compressors are often equipped with efficient filtration systems to ensure the purity of the hydrogen dispensed into vehicles.

How Dose the Hydrogen Compressor Working in a Hydrogen Refueling Station?

- Low-pressure Hydrogen Inlet: Low-pressure hydrogen enters the compressor from the hydrogen supply source.

- Multi-stage Compression: The hydrogen undergoes multiple stages of compression within the compressor, gradually increasing its pressure.

- Cooling: The heat generated during compression is dissipated through a cooling system.

- Hydrogen Storage: The high-pressure hydrogen is transported to the storage tank for storage.

- Hydrogen Fueling: Vehicles enter the refueling station and receive high-pressure hydrogen from the fueling dispenser into their hydrogen fuel cell system.

Three Importances of Hydrogen Compressors in Hydrogen Refueling Stations

- Ensuring Operating Efficiency: High-efficiency hydrogen compressors improve the operating efficiency of refueling stations and reduce fueling time.

- Ensuring Hydrogen Quality: High-purity hydrogen extends the lifespan of fuel cells and improves vehicle performance.

- Safety Assurance: Hydrogen compressors must have comprehensive safety protection measures to ensure the safe operation of refueling stations.

Five Benefits for Hydrogen Refueling Station Operators

By choosing a Keepwin diaphragm hydrogen compressor, refueling station operators can benefit from:

- Reduced operating costs: High efficiency and minimal maintenance requirements contribute to lower operating costs.

- Improved reliability: The robust design and advanced materials ensure long-term reliability.4000 hours non stop operation.

- Enhanced safety: The diaphragm design and safety features minimize the risk of accidents.

- Compliance with industry standards: Keepwin compressors meet or exceed all relevant industry standards and regulations.

- Environmental sustainability: 100% oil free, 0 Pollution to the gas medium.

为什么选择我们

发现 keepwin 的与众不同

全世界的制造商都将 Keepwin 作为顶级压缩机制造商,这是有原因的。从工业制造到能源工业,以及介于两者之间的所有领域,我们的系统 20 多年来一直深受 100 多个国家和地区的信赖。

准备好将您的行业提升到新的高度了吗?继续阅读,了解 Keepwin 为何是气体压缩机的不二之选

严格的质量控制

按照 ISO9001 ISO14001 标准生产。获得 CE TUV ASMI 等证书

经验丰富的工程师

经验丰富的工程师,拥有 39 年丰富的压缩机设计专业知识

咨询和定制

从设计到安装,我们的压缩机解决方案可为您节省时间和精力。

最佳能源工厂和奖项

从近 22 年的经验中获益。

我们的工作方式

我们的解决方案让您轻松开展项目工作

多年来,Keepwin 一直是高性能压缩机的领先制造商,为各行各业提供服务。凭借广泛的研发专长,我们可以提供定制工程解决方案,以满足您的特定需求。我们的全球分销商网络可提供可靠的售后支持,确保您的运营顺利进行。

设计与制作

根据您的需求和现场条件进行精确计算和设计

加工和装配

购买原材料、锻造部件并组装压缩机

试运行和油漆

在氮气条件下进行 4 小时出厂试运行

运输和佣金

将压缩机运送到您的现场,并提供现场调试。