工业压缩机房是为关键工艺提供压缩空气或气体的关键场所。然而,它们也意味着巨大的能源消耗、设备磨损和停机风险。通过采用 数字工具 工业压缩机房因此,运营商可以优化性能、加强维护并降低成本。

1.先进的压缩机控制器

现代控制器(如阿特拉斯-科普柯的 Elektronikon)具有触摸屏界面、远程连接和智能排序功能,可根据需求匹配输出。这些 压缩机房监控系统 简化操作,减少人工巡视,提高能效至少 10-20% .

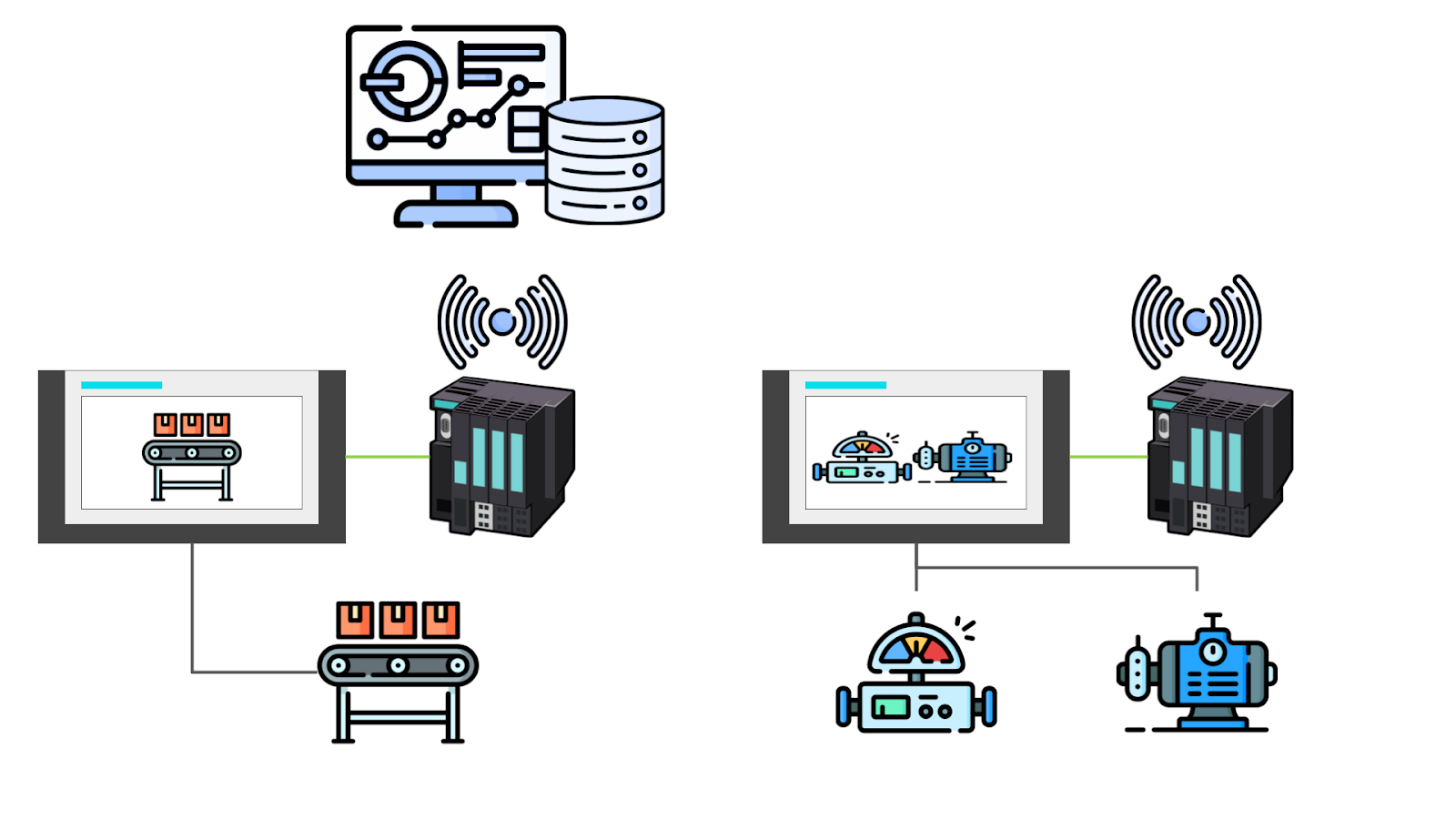

2.物联网和边缘监控传感器

嵌入 物联网压缩机分析 传感器(振动、压力、温度)实现实时状态跟踪。边缘计算平台可对异常情况进行本地分析,最大限度地减少延迟和对云的依赖。这样就能在轴承或阀门出现故障前对其进行预测性检测。 .

3.预测性维护软件

工具 预测性维护压缩机 跟踪传感器历史趋势并预测故障。例如,通过振动分析可发现偏差或磨损,而无需进行侵入式检查。这种方法将维护工作从被动反应转变为主动出击,最多可减少停机时间 30% .

4.能源管理仪表板

系统,如能源部的 AIRMaster+ 和先进的能源管理软件收集和分析压缩机的能源使用、气流和压力。这些数字工具可突出显示效率低下的问题,如漏气、需求过大、机组性能不佳等,从而实现可操作的能源节约。

5.远程车队监控和云分析

数字连接将多个压缩机房整合到统一的平台(如西门子 MindSphere)上,从而实现整个机队的基准测试、KPI 跟踪和远程控制。此类系统可加速故障检测并支持集中决策 .

6.自动控制与系统集成

自动化 SCADA/EMS 集成 以及 PROFIenergy 等协议可实现动态负载平衡和功率优化。将压缩机自动化与基于时间表的能源管理系统相结合,可确保设备仅在需要时运行,从而减少机械磨损和运行成本.

效益摘要

| 工具 | 主要效益 |

|---|---|

| 智能控制器 | 需求匹配效率 |

| 物联网传感器+边缘 | 实时问题检测 |

| 预测软件 | 主动预防故障 |

| EMS 仪表板 | 能源优化见解 |

| 云车队管理 | 集中运行控制 |

| 自动集成 | 最大限度减少人工干预 |

为什么这些对工业用户很重要

-

正常运行时间增加:从可靠预报到早期故障预警

-

节约能源:智能排序和泄漏检测

-

维护效率:根据实际需求安排日程

-

数据驱动决策:跨单位和站点的可见性

KEEPWIN 的集成能力

KEEPWIN 提供从传感器部署到云仪表盘和 EMS/SCADA 连接的全栈数字解决方案。我们的客户通常会看到 20-30% 低能耗, 40% 减少紧急维修次数并简化了压缩机房的操作。

在当今的工业领域,配备了物联网、边缘分析、能源仪表板、预测性维护、远程控制和自动化等数字化工具的压缩机房将成为性能强大的地方。采用这 6 种数字化工具,让您的运营更高效、更可靠、更智能。