- 电子邮件:keepwin@keep-win.com

- 热线电话 : +86 13910684359

相关气体天然气又称火炬气或套管气,是原油开采的一种天然副产品。当石油被带到地面时,溶解在石油中的天然气也会被释放出来。在许多情况下,由于缺乏基础设施或处理能力,这些气体会被燃烧掉。

然而,如果 气体压缩和回收在这种情况下,伴生气可以从废物转化为 原料支持能源可持续发展目标和遵守法规。

| 流量 | 1250 Nm³/h(标准状态) |

| 吸气压力 | 0.5Mpa(G) |

| 排放压力 | 40.0 兆帕(G) |

| 放电温度 | ≤130°C(无后冷却器) |

| 电机功率 | 280 千瓦 |

| 冷却方式 | 风冷式(无需水) |

| 保护等级 | IP55 / F 级 |

| 结构 | 双 V 型、空气冷却、往复活塞式压缩机 |

| 尺寸和重量 | 9000*2500*2600mm/ 16600kg |

| 噪音水平 | ≤85 dB(A) |

伴生气经压缩和处理后,可用于各行各业:

| 应用领域 | 用例示例 |

|---|---|

| 石油和天然气 | 回注、气体提升、火炬气回收 |

| 发电 | 现场燃气发动机或涡轮机 |

| 石油化工 | 制氢或合成气的原料 |

| 压缩天然气/液化天然气系统 | 转化为压缩/液化气体 |

| 环境合规 | 尽量减少火炬和碳足迹 |

伴生气中含有一种 复杂的混合碳氢化合物-如甲烷、乙烷、丙烷、丁烷、戊烷,以及 非烃杂质 如 CO₂、氮、H₂S 和氦。

专门建造的 伴生气体压缩机 具有以下优势:

✅ 可处理多组分气流

✅ 设计用于 可变压力和流量

✅ 确保 无泄漏、无油压缩

✅ 支持 高环境 和 远程场 操作

✅ 启用 能量回收 来自火炬气

在东南部油田 土耳其一家上游能源公司面临着一个反复出现的问题:大量的 伴生气 由于没有足够的压缩基础设施,这些气体被燃烧。这不仅导致 环境处罚 但也浪费了宝贵的能源资源。

客户的目标是回收和压缩这些富含碳氢化合物的火炬气,以满足以下需求 现场发电 和 气体再注入.

为此,他们需要一个高度定制的压缩机解决方案,能够处理以下问题 复杂气体成分 于 最高达 40 兆帕(400 巴)的极端排放压力.

气体成分:复杂而苛刻

气体成分:复杂而苛刻该项目中的伴生气是典型的 多组分碳氢化合物流主要包括

甲烷(CH₄):73.01%

乙烷(C₂H₆):9.9%

丙烷(C₃H₈):9.2%

丁烷、戊烷、己烷(C₄-C₆):~4%

氮(N₂):0.96%

微量氧(O₂ < 0.005%)

这种混合物在以下方面提出了独特的挑战 挥发性, 压力管理和 润滑安全.

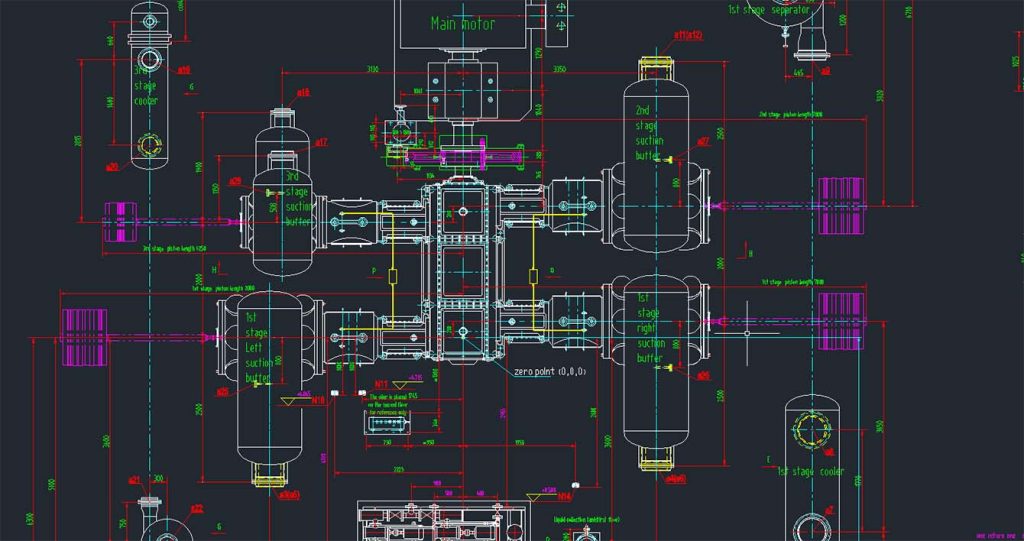

Keepwin 的解决方案:2VF-3.6/5-400 型

Keepwin 的解决方案:2VF-3.6/5-400 型为了满足这些技术要求、 Keepwin Technology Hebei Co. 交付了完全定制的双 V-5 级风冷往复式压缩机模型 2VF-3.6/5-400能够压缩来自 0.5 兆帕(克) 至 40 兆帕(克).

主要规格

主要规格| 项目 | 价值 |

|---|---|

| 容量流量 | 1250 牛米³/小时(3.6 立方米/分钟) |

| 压缩阶段 | 5 |

| 冷却类型 | 风冷式(无需水) |

| 润滑 | 轴油 + 缸油喷射 |

| 排放温度 | ≤160°C |

| 电机功率 | 280 kW,dIIBT4,防爆型 |

| 驱动系统 | 弹性直接耦合 |

| 启动方法 | 软启动 |

| 控制系统 | PLC + 变送器 + 触摸屏 |

| 足迹 | 9000×2500×2600 毫米 |

| 重量 | 16 600 千克 |

提供交钥匙工程

提供交钥匙工程除压缩机橇外,Keepwin 还提供了:

PLC 防爆控制柜

冷却器 + 轴流风扇冷却系统

缓冲罐和阀门管道

注油+排污系统

气体泄漏检测 + 安全警报

带照明和环境加热装置的机舱罩

全套配件包:随机备件、工具、手册

这种交钥匙设计使客户能够 快速集成只需进行最少的现场改造。

成果和影响

成果和影响试运行后,该系统使客户能够

"(《世界人权宣言》) 2VF-3.6/5-400 该设备已可靠运行 6000 多小时,只需进行标准维护。

| 特点 | Keepwin 优势 |

|---|---|

| ✅ 无油技术 | 无气体污染,无需油分离 |

| ✅ 模块化、定制设计 | 按流量、压力和成分规格制造 |

| ✅ 经现场验证的性能 | 在超过 35 个国家开展业务,包括中东和中亚地区 |

| ✅ 重型工程 | 锻造曲轴,防腐蚀涂层,B 级/F 级发动机 |

| ✅ 40 多年的技术专长 | 内部研发、加工和全系统集成 |

| ✅ 快速交付 | 标准设备 45-60 个工作日内准备就绪 |

无论您是要开发气举系统、最大限度地减少燃烧排放,还是要为现场发动机提供动力--基普文都能提供 端到端压缩解决方案 用于最复杂的伴生气流。

📩 联系我们 于 keepwin@keep-win.com

🌐 参观: www.keep-win.com

📞 咨询 我们的工程师可提供技术咨询或 3D 布局建议。

全世界的制造商都将 Keepwin 作为顶级压缩机制造商,这是有原因的。从工业制造到能源工业,以及介于两者之间的所有领域,我们的系统 20 多年来一直深受 100 多个国家和地区的信赖。

准备好将您的行业提升到新的高度了吗?继续阅读,了解 Keepwin 为何是气体压缩机的不二之选

按照 ISO9001 ISO14001 标准生产。获得 CE TUV ASME 等证书

经验丰富的工程师,拥有 39 年丰富的压缩机设计专业知识

从设计到安装,我们的压缩机解决方案可为您节省时间和精力。

从近 22 年的经验中获益。

多年来,Keepwin 一直是高性能压缩机的领先制造商,为各行各业提供服务。凭借广泛的研发专长,我们可以提供定制工程解决方案,以满足您的特定需求。我们的全球分销商网络可提供可靠的售后支持,确保您的运营顺利进行。

根据您的需求和现场条件进行精确计算和设计

购买原材料、锻造部件并组装压缩机

在氮气条件下进行 4 小时出厂试运行

将压缩机运送到您的现场,并提供现场调试。

我们将安排专业工程师设计出适合您需求的解决方案。

*我们尊重您的隐私。提交后,我们的 Keepwin 专家将尽快与您联系。