Industrial compressors are essential equipment across sectors such as energy, chemicals, metallurgy, electronics, and medical gas supply. Choosing the correct compressor type directly affects system efficiency, operational stability, and safety. This document outlines the major categories of compressors and offers a structured guide to help professionals select the most suitable one for their applications.

🔧 1. Reciprocating Compressors

🔧 1. Reciprocating Compressors

Overview:

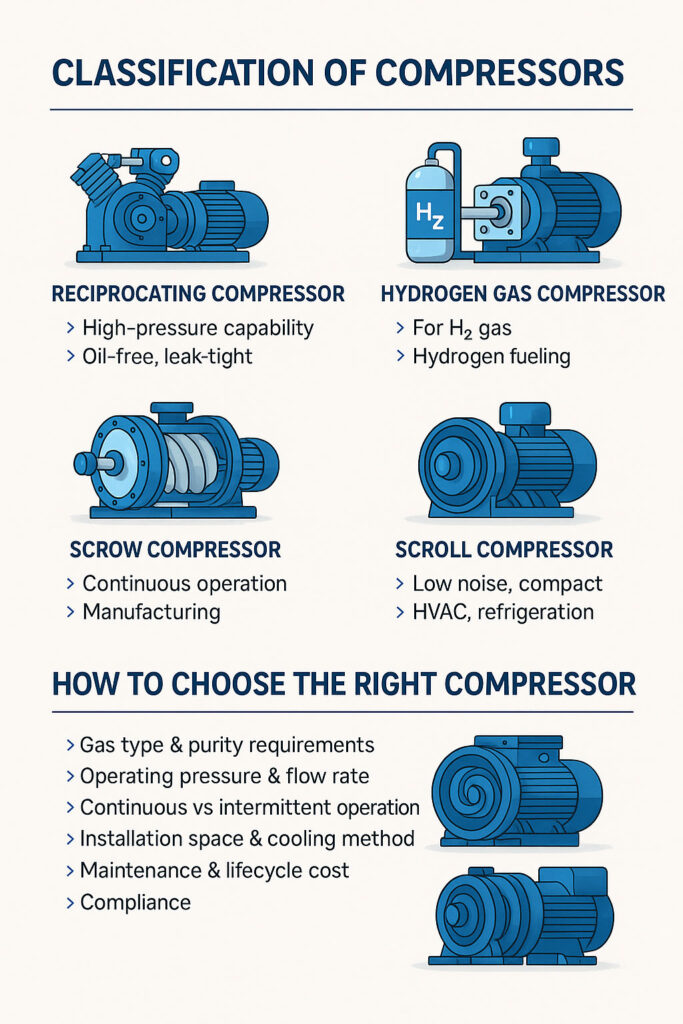

Reciprocating compressors use pistons driven by a crankshaft to deliver gas at high pressure.

Advantages:

High-pressure capability

Suitable for small to medium flow rates

Modular maintenance

Best for:

Petrochemical plants, natural gas boosting, CNG stations

💡 2. Diaphragm Compressors

Overview:

These are oil-free compressors that use a diaphragm to isolate the gas from mechanical parts.

Advantages:

Absolutely oil-free gas delivery

Ideal for high-purity and hazardous gases

Leak-tight design

Best for:

Hydrogen, oxygen, helium, and medical gas compression

⚙️ 3. Screw Compressors (Rotary Compressors)

Overview:

Rotary screw compressors are continuous-duty machines that compress gas using two helical rotors.

Advantages:

Continuous operation

Lower vibration

High efficiency for medium pressure ranges

Best for:

Manufacturing, electronics, metallurgy, pneumatic tools

🌀 4. Scroll Compressors

Overview:

Scroll compressors use orbiting scrolls to compress gas.

Advantages:

Quiet operation

Energy-efficient

Compact footprint

Best for:

HVAC, refrigeration, laboratories

💨 5. Centrifugal Compressors

Overview:

These dynamic compressors use impellers to impart velocity to the gas and convert it into pressure.

Advantages:

High flow capacity

Fewer moving parts

Suitable for large-scale operations

Best for:

Air separation plants, LNG, chemical processes

🔬 6. Hydrogen Gas Compressors

Overview:

Specialized units designed to handle light, explosive hydrogen gas under high pressure.

Advantages:

Diaphragm or oil-free piston types preferred

High compression ratios

Excellent sealing and safety

Best for:

Hydrogen fueling stations, renewable energy storage, ammonia production

⚖️ 7. Scroll vs Screw vs Reciprocating: Quick Comparison

| Type | Pressure Range | Flow Capacity | Maintenance | Typical Use Case |

|---|---|---|---|---|

| Reciprocating | High | Low–Medium | Moderate | Gas pipeline, CNG |

| Diaphragm | High | Low | Low | Specialty gases, labs |

| Screw | Medium | Medium–High | Low | Industrial automation |

| Scroll | Low–Medium | Low | Low | HVAC, refrigeration |

| Centrifugal | Low–Medium | High | Low | LNG, large-scale processes |

| Hydrogen Compressors | Very High | Low–Medium | Medium–High | Hydrogen energy, clean tech |

🧭 How to Choose the Right Compressor

When selecting a compressor, consider the following factors:

Gas type & purity requirements (e.g., toxic, explosive, high-purity)

Operating pressure & flow rate

Continuous vs intermittent operation

Installation space & cooling method

Maintenance & lifecycle cost

Compliance (CE, ATEX, ISO certifications)

🔧 1. Reciprocating Compressors

🔧 1. Reciprocating Compressors