Gás associadoO gás de flare, também conhecido como gás de flare ou gás de casinghead, é um subproduto natural da extração de petróleo bruto. Quando o petróleo é trazido à superfície, o gás natural dissolvido no petróleo também é liberado. Em muitos casos, esse gás é queimado devido à falta de infraestrutura ou capacidade de processamento.

No entanto, com a devida compressão e recuperação de gásO gás associado pode ser transformado de resíduo em um combustível ou matéria-prima valiosaA empresa está pronta para atender às metas de sustentabilidade energética e à conformidade regulatória.

| Taxa de fluxo | 1250 Nm³/h (condições padrão) |

| Pressão de sucção | 0,5Mpa(G) |

| Pressão de descarga | 40,0Mpa(G) |

| Temp. de descarga | ≤130°C (sem pós-resfriador) |

| Potência do motor | 280KW |

| Método de resfriamento | Resfriado a ar (não precisa de água) |

| Classe de proteção | IP55 / Classe F |

| Estrutura | Compressor de pistão alternativo tipo duplo V, resfriado a ar |

| Tamanho e peso | 9000*2500*2600mm/ 16600kg |

| Nível de ruído | ≤85 dB(A) |

O gás associado, uma vez comprimido e tratado, encontra aplicação em vários setores:

| Área de aplicação | Exemplo de caso de uso |

|---|---|

| Petróleo e gás | Reinjeção, elevação de gás, recuperação de gás de flare |

| Geração de energia | Motores ou turbinas a gás no local |

| Petroquímico | Matéria-prima para produção de hidrogênio ou gás de síntese |

| Sistemas de GNC / GNL | Conversão em gás comprimido/liquidado |

| Conformidade ambiental | Minimização de flare e redução da pegada de carbono |

O gás associado contém um mistura complexa de hidrocarbonetos-como metano, etano, propano, butano e pentano, bem como impurezas não relacionadas a hidrocarbonetos como CO₂, nitrogênio, H₂S e hélio.

Um sistema de compressor de gás associado oferece as seguintes vantagens:

Manipula fluxos de gás multicomponentes

Projetado para pressão e fluxo variáveis

✅ Garante compressão sem vazamentos e sem óleo

✅ Suportes ambiente elevado e campo remoto operação

✅ Permite recuperação de energia do gás de flare

Nos campos de petróleo do sudeste TurquiaNa década de 1990, uma empresa de energia upstream enfrentou um problema recorrente: grandes volumes de gás associado estavam sendo queimados devido à infraestrutura de compressão insuficiente. Isso não só causou penalidades ambientais mas também desperdiçou recursos energéticos valiosos.

O objetivo do cliente era recuperar e comprimir esse gás de flare - rico em hidrocarbonetos - para geração de energia no local e reinjeção de gás.

Para isso, eles precisavam de uma solução de compressor altamente personalizada, capaz de lidar com composições complexas de gás em pressões extremas de descarga de até 40 MPa (400 bar).

Composição do gás: Complexo e exigente

Composição do gás: Complexo e exigenteO gás associado nesse projeto foi um típico fluxo de hidrocarbonetos multicomponentes, consistindo principalmente de:

Metano (CH₄): 73.01%

Etano (C₂H₆): 9,9%

Propano (C₃H₈): 9,2%

Butanos, pentanos, hexanos (C₄-C₆): ~4%

Nitrogênio (N₂): 0,96%

Traços de oxigênio (O₂ < 0,005%)

Essa mistura apresentou desafios únicos em termos de volatilidade, gerenciamento de pressãoe segurança de lubrificação.

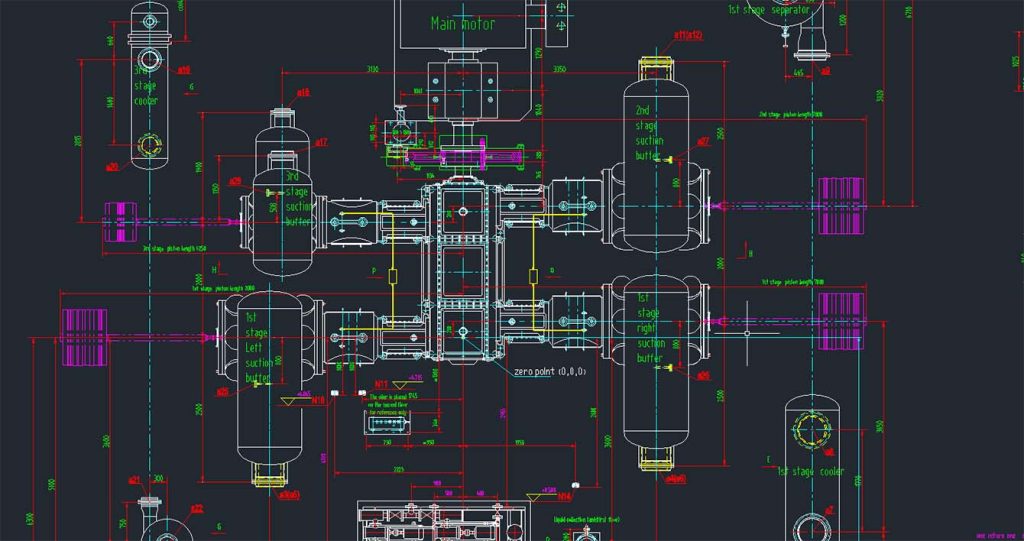

Solução da Keepwin: Modelo 2VF-3.6/5-400

Solução da Keepwin: Modelo 2VF-3.6/5-400Para atender a essas demandas técnicas, Keepwin Technology Hebei Co., Ltd. entregou um V duplo totalmente personalizado-Compressor alternativo refrigerado a ar de 5 estágios, modelo 2VF-3.6/5-400capaz de comprimir gás de 0,5 MPa (g) para 40 MPa (g).

Principais especificações:

Principais especificações:| Item | Valor |

|---|---|

| Fluxo de capacidade | 1250 Nm³/h (3,6 m³/min) |

| Estágios de compressão | 5 |

| Tipo de resfriamento | Resfriado a ar (sem necessidade de água) |

| Lubrificação | Injeção de óleo no eixo + óleo no cilindro |

| Temperatura de descarga | ≤160°C |

| Potência do motor | 280 kW, dIIBT4, à prova de explosão |

| Sistema de acionamento | Acoplamento elástico direto |

| Método de início | Partida suave |

| Sistema de controle | PLC + transmissor + tela sensível ao toque |

| Pegada ecológica | 9000×2500×2600 mm |

| Peso | 16.600 kg |

Escopo Turnkey fornecido

Escopo Turnkey fornecidoAlém do skid do compressor, a Keepwin forneceu:

Gabinete de controle PLC à prova de explosão

Resfriador + sistema de resfriamento com ventilador axial

Tanque tampão e tubulação de válvulas

Injeção de óleo + sistema de esgoto

Detecção de vazamento de gás + alarmes de segurança

Cobertura da cabine com iluminação + aquecimento ambiental

Kit completo de acessórios: peças de reposição aleatórias, ferramentas, manuais

Esse projeto pronto para uso permitiu que o cliente integrar rapidamentecom o mínimo de modificações no local.

Resultados e impacto

Resultados e impactoApós o comissionamento, o sistema permitiu que o cliente

O 2VF-3.6/5-400 A unidade tem operado de forma confiável por mais de 6.000 horas, apenas com manutenção padrão.

| Recurso | Vantagem Keepwin |

|---|---|

| ✅ Tecnologia livre de óleo | Sem contaminação de gás, sem necessidade de separação de óleo |

| ✅ Modular, projeto personalizado | Construído de acordo com as especificações de vazão, pressão e composição |

| ✅ Desempenho comprovado em campo | Operando em mais de 35 países, incluindo o Oriente Médio e a Ásia Central |

| ✅ Engenharia para serviços pesados | Virabrequim forjado, revestimentos anticorrosivos, motores Classe B/F |

| ✅ Mais de 40 anos de experiência técnica | P&D interno, usinagem e integração de todo o sistema |

| ✅ Entrega rápida | Unidades padrão prontas em 45 a 60 dias úteis |

Não importa se você está desenvolvendo um sistema de elevação de gás, minimizando as emissões de queima ou alimentando motores no local - a Keepwin fornece soluções de compressão de ponta a ponta para os fluxos de gás associados mais complexos.

📩 Entre em contato conosco em keepwin@keep-win.com

🌐 Visitar: www.keep-win.com

📞 Consultar nossos engenheiros para obter orientação técnica ou propostas de layout 3D.

Há uma razão pela qual os fabricantes de todo o mundo recorrem à Keepwin como o principal fabricante de compressores. Desde a fabricação industrial até a indústria de energia e tudo o mais, nossos sistemas são confiáveis em mais de 100 países e regiões há mais de 20 anos.

Pronto para levar seu setor a novos patamares? Continue lendo para saber o que faz da Keepwin a escolha certa para compressores de gás

Fabricado de acordo com as normas ISO9001 e ISO14001. Possui certificado CE TUV ASME Etc

Engenheiro altamente experiente, com 39 anos de ampla experiência em projetos de compressores

Do projeto à instalação, nossa solução de compressor economiza seu tempo e esforço.

se beneficiam de quase 22 anos de experiência.

Durante anos, a Keepwin tem sido um fabricante líder de compressores de alto desempenho, atendendo a uma ampla gama de setores. Com nossa ampla experiência em P&D, podemos fornecer soluções de engenharia personalizadas para atender às suas necessidades específicas. Nossa rede global de distribuidores oferece suporte pós-venda confiável para garantir que suas operações ocorram sem problemas.

Cálculos e projetos precisos com base em suas necessidades e condições do local

Comprar matérias-primas, forjar componentes e montar o compressor

Passa por um teste de fábrica de 4 horas em condições de nitrogênio

Entregar o compressor em suas instalações e fornecer o comissionamento no local.

Obtenha o projeto de compressor mais preciso em pouco tempo.

Nós providenciaremos um engenheiro profissional para projetar uma solução que atenda às suas necessidades.

*Respeitamos sua privacidade. Após o envio, nossos especialistas dedicados da Keepwin entrarão em contato o mais breve possível.