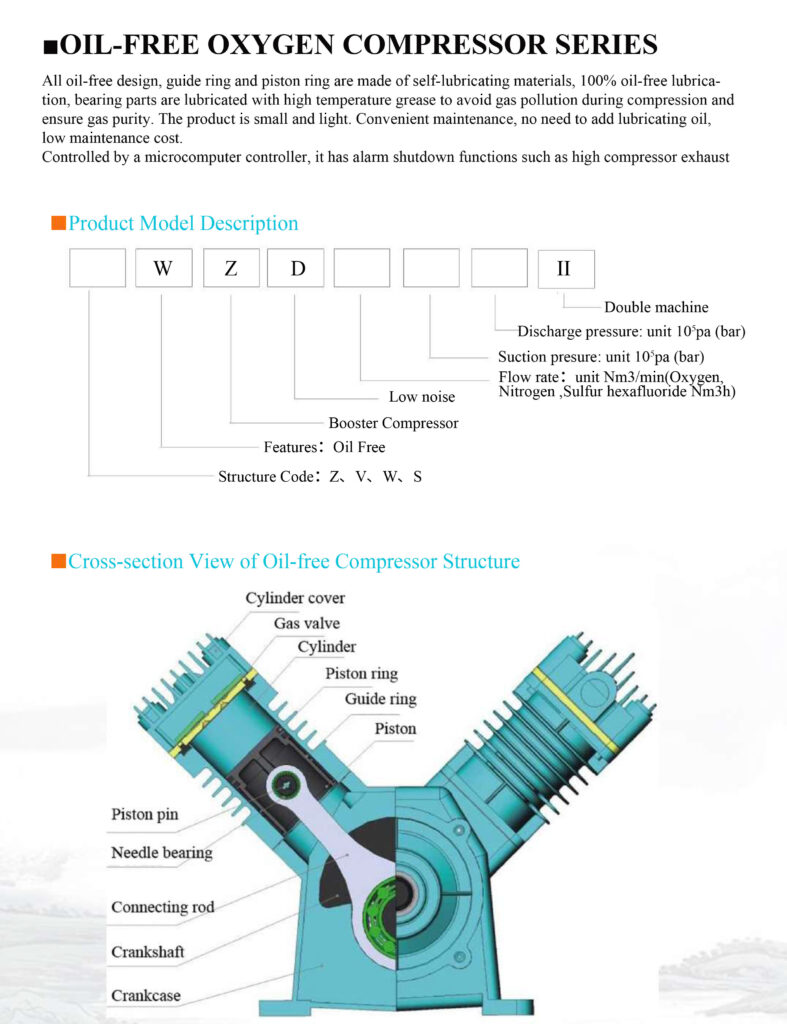

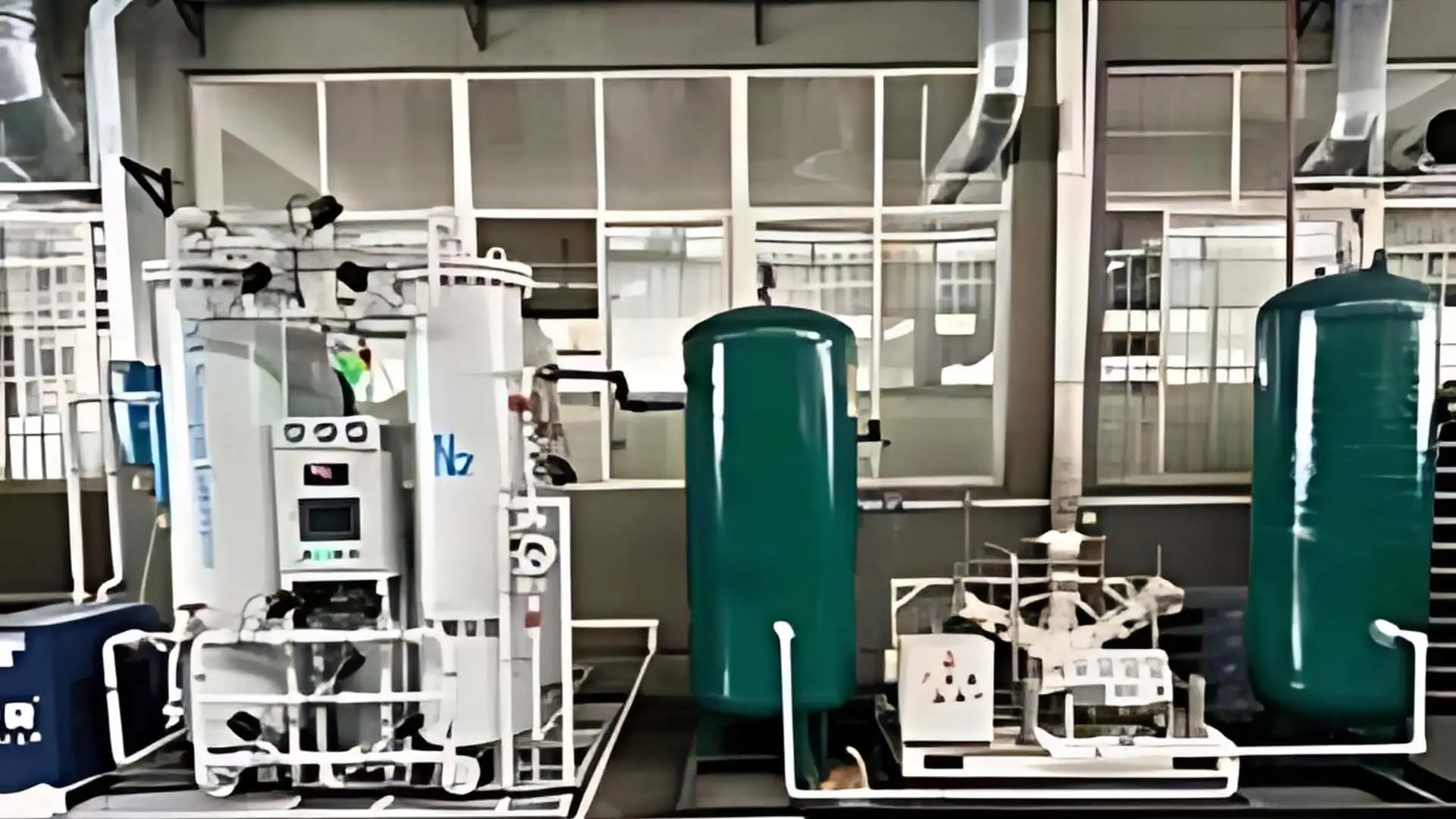

Small Oil Free Piston Compressors

Experience the benefits of our oil-free piston compressors: reliable, efficient, and quiet operation. Ideal for applications requiring the highest levels of air purity, our compressors are designed to meet your most demanding needs.

"When we chose Keepwin to provide helium membrane compressors three years ago and signed a 100-day contract, they exceeded all expectations. Keepwin completed the production plan, engineering drawings, and equipment commissioning ahead of schedule, showcasing their exceptional professionalism and efficiency."

Александр Сергеевич Purchase Manager