산업용 컴프레서실은 중요한 공정에 압축 공기 또는 가스를 공급하는 중추적인 역할을 합니다. 하지만 상당한 에너지 소비, 장비 마모, 가동 중단의 위험도 존재합니다. 다음을 채택함으로써 디지털 도구 산업용 컴프레서 룸를 통해 운영자는 성능을 최적화하고 유지보수를 강화하며 비용을 절감할 수 있습니다.

1. 고급 컴프레서 컨트롤러

아트라스콥코의 일렉트로니콘과 같은 최신 컨트롤러는 터치스크린 인터페이스, 원격 연결, 스마트 시퀀싱을 통해 출력을 수요에 맞게 조정할 수 있는 기능을 갖추고 있습니다. 이러한 컴프레서 룸 모니터링 시스템 운영 간소화, 수동 라운드 감소, 에너지 효율성 최소 10-20% 향상 .

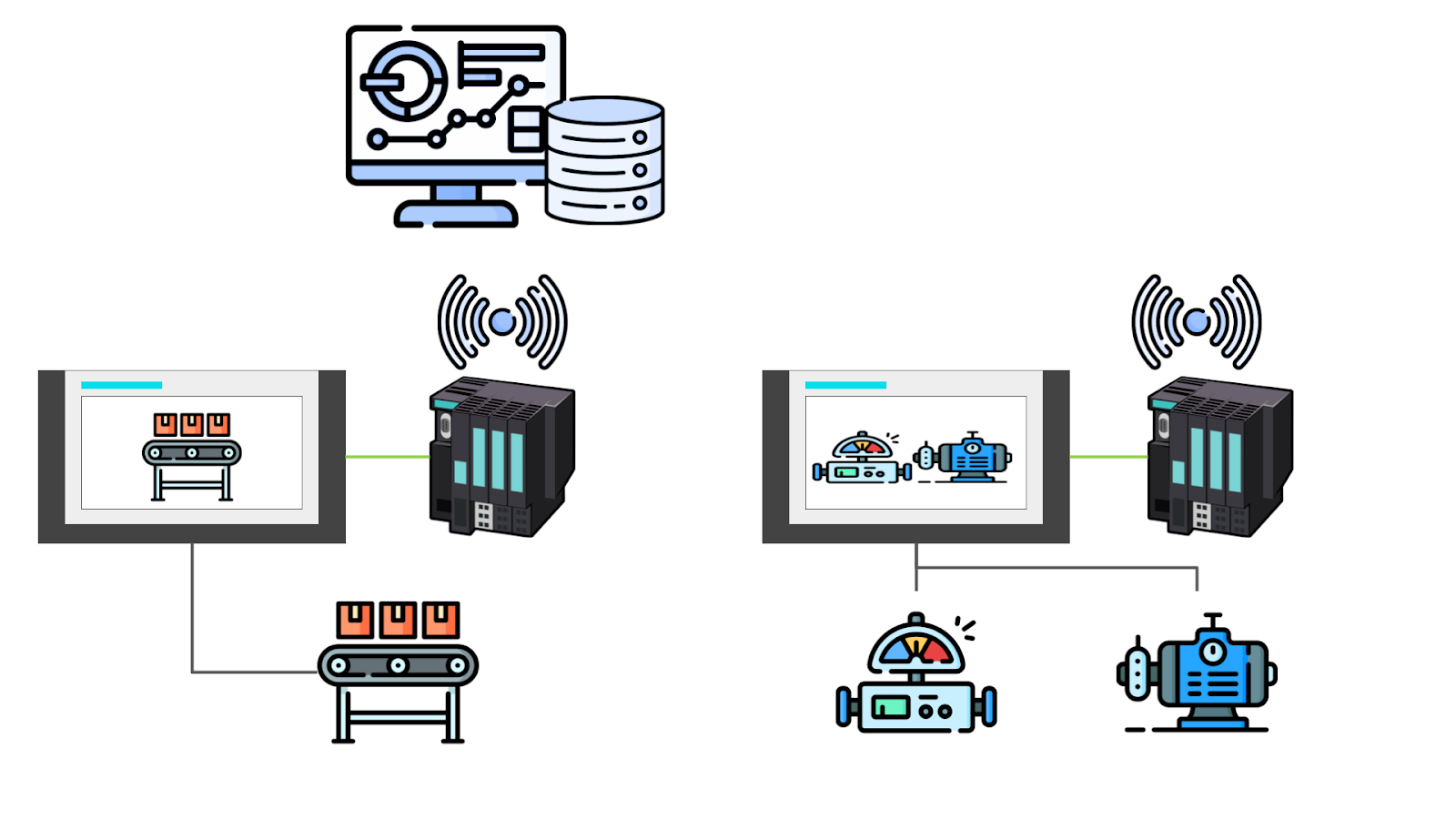

2. IoT 및 엣지 모니터링 센서

임베딩 IIoT 컴프레서 분석 센서(진동, 압력, 온도)를 통해 실시간 상태 추적이 가능합니다. 엣지 컴퓨팅 플랫폼은 이상 징후를 로컬에서 분석하여 지연 시간과 클라우드 의존도를 최소화합니다. 이를 통해 고장 전에 베어링 또는 밸브 문제를 예측적으로 감지할 수 있습니다. .

3. 예측 유지보수 소프트웨어

다음용 도구 예측 유지보수 컴프레서 과거 센서 추세를 추적하고 오류를 예측할 수 있습니다. 예를 들어, 진동 분석은 침습적인 검사 없이도 정렬 불량이나 마모를 파악할 수 있습니다. 이 접근 방식은 유지보수를 사후 대응에서 사전 예방으로 전환하여 가동 중단 시간을 최대 30%까지 줄여줍니다. .

4. 에너지 관리 대시보드

DOE와 같은 시스템 AIRMaster+ 및 고급 에너지 관리 소프트웨어는 컴프레서 에너지 사용량, 공기 흐름 및 압력을 수집하고 분석합니다. 이러한 디지털 도구는 누수, 과도한 수요, 성능 저하 등 비효율적인 부분을 강조하여 실행 가능한 에너지 절감 효과를 제공합니다.

5. 원격 차량 모니터링 및 클라우드 분석

디지털 연결은 여러 컴프레서 룸을 통합 플랫폼(예: 지멘스 마인드스피어)으로 통합하여 차량 전체의 벤치마킹, KPI 추적 및 원격 제어를 가능하게 합니다. 이러한 시스템은 고장 감지를 가속화하고 중앙 집중식 의사 결정을 지원합니다. .

6. 자동 제어 및 시스템 통합

자동화된 SCADA/EMS 통합 와 같은 프로토콜을 통해 동적 부하 분산 및 전력 최적화가 가능합니다. 컴프레서 자동화와 스케줄 기반 에너지 관리 시스템을 결합하면 필요할 때만 장치를 가동하여 기계 마모와 운영 비용을 줄일 수 있습니다..

혜택 요약

| 도구 | 주요 혜택 |

|---|---|

| 스마트 컨트롤러 | 수요에 맞춘 효율성 |

| IIoT 센서 + 엣지 | 실시간 문제 감지 |

| 예측 소프트웨어 | 사전 예방적 장애 예방 |

| EMS 대시보드 | 에너지 최적화 인사이트 |

| 클라우드 차량 관리 | 중앙 집중식 운영 제어 |

| 자동화된 통합 | 수동 개입 최소화 |

이것이 산업 사용자에게 중요한 이유

-

가동 시간 향상: 신뢰할 수 있는 예측 및 조기 오류 경고에서

-

에너지 절약: 스마트 시퀀싱 및 누출 감지

-

유지 관리 효율성: 실제 필요에 따른 일정

-

데이터 기반 의사 결정: 부서 및 사이트 전반의 가시성

KEEPWIN의 통합 기능

킵윈은 센서 배포부터 클라우드 대시보드, EMS/SCADA 연동까지 풀스택 디지털 솔루션을 제공합니다. 고객은 일반적으로 20-30% 에너지 사용량 감소, 긴급 수리 40% 감소압축기실 운영을 간소화했습니다.

오늘날의 산업 환경에서 IoT, 엣지 분석, 에너지 대시보드, 예측 유지보수, 원격 제어 및 자동화와 같은 디지털 도구를 갖춘 컴프레서 룸은 성능 강화의 중심이 됩니다. 다음 6가지 디지털 도구를 도입하여 효율성, 안정성, 데이터 인텔리전스를 통해 운영 역량을 강화하세요.