石油化学プラントでは、コンプレッサーステーションはミッションクリティカルでありながら、建設に時間がかかることが多い。 モジュール式スキッドマウントコンプレッサ 工場でテスト済みの組み立て済みユニットにより、現場での作業、スケジュールリスク、設置コストを劇的に削減します。

1.オフサイト製造=迅速な配備

モジュール式コンプレッサースキッドは、完全に管理された工場条件下で製造され、溶接、配管、制御パネル、テストの大部分が事前に行われ、80-90%完成品として現地に到着します。このアプローチにより、天候の遅れを回避し、土木工事の干渉を最小限に抑え、以下のことが可能になります。 パラレル構造プロジェクトのスケジュールを大幅に短縮 .

2.安定した品質と低いリスク

工場で製造されたモジュールは、以下のような厳しい品質保証を受けている。 FAT(工場受入試験)出荷前に信頼性の高い動作を保証します。これにより、現場での施工ミスを回避し、API/ASME規格への適合性を向上させ、システム全体の完全性を高めます。 .

3.設備投資と設置コストの削減

モジュラー・スキッドは、現場での労働力、足場、現場サポートを最小限に抑えます。 人件費と土木費の削減さらに、既存事業のダウンタイムを削減する。

4.柔軟性と拡張性の強化

プラントのニーズの変化に応じて、コンプレッサスキッドを既存のシステムに容易に統合できます。スキッドは以下を提供します。 プラグアンドプレイの拡張性段階的な拡張や一時的なニーズに最適です。また、必要に応じて移設や再利用が可能で、資産の寿命を延ばすことができます。 .

5.より安全で制御された組立環境

工場の作業場は、天井クレーン、管理された溶接ラボ、標準化された手順など、厳格な安全慣行に従っている。この 現場での安全事故を減らす特に混雑した石油化学プラントにおいて .

スキッド式とスティック式コンプレッション・システムの比較

| 特徴 | スティックビルド・システム | スキッド搭載コンプレッサー |

|---|---|---|

| 設置時間 | ヶ月の現場作業 | プラグアンドプレイでセットアップ可能なウィークス |

| 品質保証 | 天候に左右される | 工場テスト済み、認証済み |

| 土木・現場作業 | 広範なインフラ | 最小限の接続と土台 |

| スケーラビリティ | 複雑な展開 | モジュール式アドオンで簡単に拡張可能 |

| 安全性と信頼性 | 高いフィールドリスク | より安全なワークショップの建設、事故の減少 |

石油化学プロジェクトでの応用

-

ガス注入ステーション

-

フィードストックライン用ブースターコンプレッション

-

減圧蒸留装置での再圧縮

-

水素、LPG、CO₂リサイクルシステム

モジュール式コンプレッサースキッドは、試運転を簡素化し、プラントの中断を最小限に抑えます。

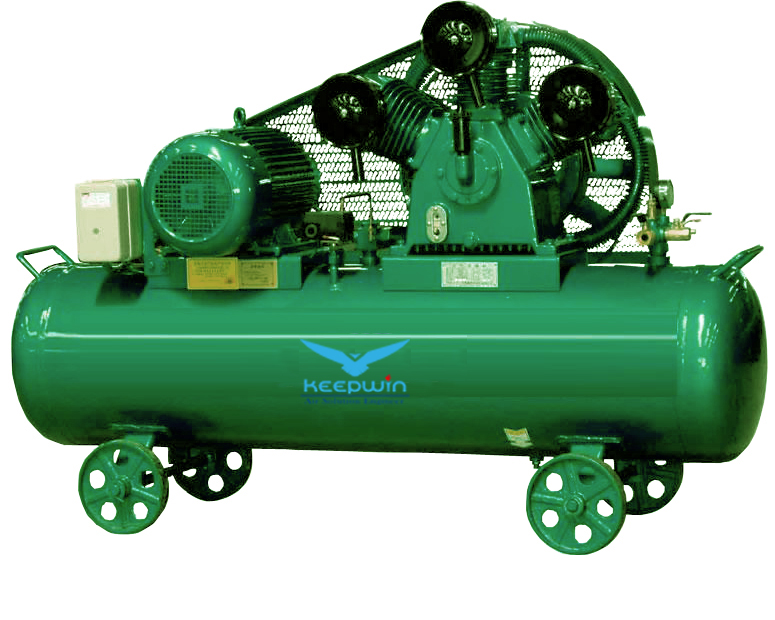

KEEPWINが世界をリードする理由

KEEPWINは完全に統合されたコンプレッサースキッドを設計しています:

-

スクリュー、レシプロ、またはダイヤフラムコンプレッサー

-

計装・制御盤

-

フィルター、クーラー、バルブ、脈動ダンパー

-

事前配線とパネルPLC/SCADAテスト

当社のモデルは、迅速なスタートアップ、高効率、石油化学グレードの安全性を実現するために設計された、ターンキー・プラグアンドプレイ・システムを提供します。

結論

石油化学エンジニアリングでは、タイミング、品質、柔軟性は譲れない。 モジュール式スキッドマウントコンプレッサ CAPEXを削減し、スケジュールを加速し、安全性を強化します。KEEPWINのカスタマイズされたコンプレッサスキッドを使用することで、施設は納期を短縮し、拡張を簡素化し、準拠した高性能な運転を保証することができます。

👉 コンプレッサーの設置をお急ぎですか? 連絡先 キープウィン 詳細なスキッド・コンプレッサー・ソリューション・パッケージについては、今すぐお問い合わせください!