LPGコンプレッサーが今、進化しなければならない理由

水素の急務:LPGコンプレッサーが今すぐ進化しなければならない理由 2030年までに、EUの排出基準は、LPGシステムに最低10%の体積濃度での水素混合を義務付け、2040年までに25%まで上昇させる 57。このシフトは、メタン排出(GWP 84x CO₂)を削減し、カーボンニュートラルを加速することを目的としている。従来のコンプレッサーはここで失敗する:水素透過は、5%以上のH₂ブレンドでバルブの脆化、シールの劣化、マイクロリークを引き起こす。KEEPWINのGEOシリーズは、3つのイノベーションでこれらの限界を打ち破ります:セラミックコーティングバルブスタック:ジルコニア-チタン複合層は29MPaの水素脆性に耐える:ガス組成の変動(0-20% H₂)にリアルタイムで調整。磁気ベアリングドライブ:潤滑油汚染を排除し、Scope 3排出量を40%削減 7.「水素はオプションではありません。水素はオプションではありません。

AIがLPGコンプレッサーのダウンタイムを50%削減する方法

しかし、故障の74%は、数日前に予兆が現れている。従来のメンテナンスでは、こうした兆候を見逃します。AIを活用した予測システムが、どのように事後修理を精密な予測に変えるかをご覧ください。メンテナンスに革命を起こす技術トリオ KEEPWINのAIガーディアンシステムは、以下のものを組み合わせています:振動フィンガープリンティング 0.01mmの偏差からロッドのミスアライメントを検出(ISO 10816-6認証) 熱デジタルツインズ 10,000以上の故障シナリオに対してリアルタイムの熱シグネチャを比較 エッジ分析 0.2秒で現場のデータを処理(クラウド遅延なし) *「故障の312時間前にピストンの亀裂を発見しました。従来の方法では災害の3時間前に発見していました」* - サウジアラビア、ヤンブ製油所メンテナンス主任 サウジアラムコのヤンブ施設では、36カ月で$38万ドルを節約しました。

48時間LPGコンプレッサーの設置:アフリカのクリーン・クッキングの躍進

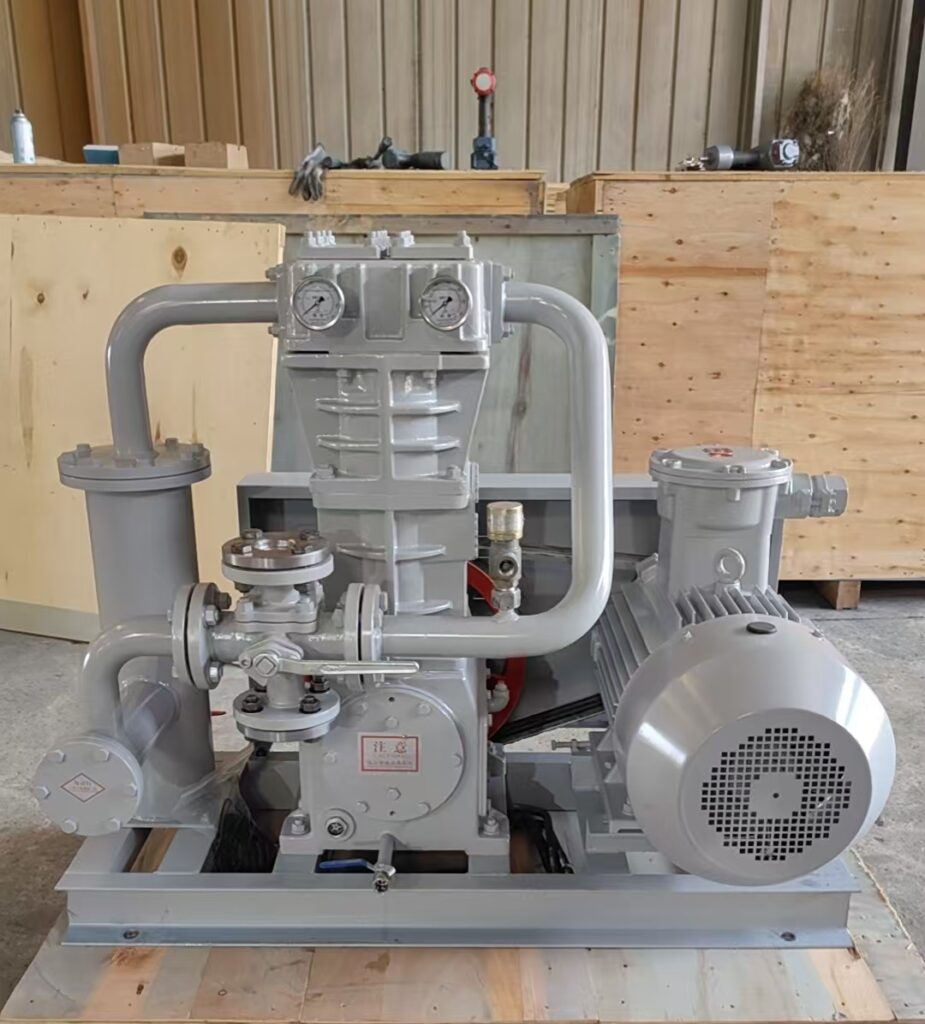

スキッド搭載コンプレッサーがアフリカのエネルギー危機を48時間で解決する方法 アフリカでは危険な調理用燃料が年間$220億消費される一方、LPG輸入の70%が圧縮インフラの欠落により港で足止めされている。モジュール式コンプレッサー技術はこのギャップを埋め、輸送コンテナを2日以内にガスハブに変えます。革新の核心プラグアンドプレイスキッドユニット KEEPWINの移動式ステーションはアフリカのトップ3の障壁を克服します:基礎が不要 ギアによるコンクリート打ちっぱなしの設置(3週間の建設期間短縮) オフグリッド運転 グリッドに接続することなくソーラーハイブリッド発電が可能 事前に設定された安全性 ATEX認定の漏洩検知器があらかじめ設置されている *「従来のプラントでは6ヶ月の建設期間が必要でした。私たちは、荷揚げ、ボルト締め、圧縮を47時間で開始しました」* - Kumasi Gas Co.ガーナ・クマシのケース:50トン/日、無 [...]...

油田用LPGコンプレッサーでOPEXを30%削減

油圧ピストンコンプレッサ油田ガスフレアに対する年間120万トンのソリューション 世界の油田では、LPGを多く含む随伴ガスのフレアにより、年間160億トンを浪費している。従来のスクリューコンプレッサーは、硫黄分が5%を超えると故障し、貴重な燃料の燃焼を余儀なくされます。油圧ピストン技術がいかに無駄を利益に変えるかをご覧ください。サワーガスで油圧システムが優れた性能を発揮する理由 KEEPWINのDY-VSeriesは、油田の課題に次のような方法で対処しています:密閉ピストンチャンバー ガスと潤滑油の接触ゼロ → H₂S腐食を排除 テフロンコーティングバルブ 18%のH₂S濃度に耐える(業界平均:5%) 適応圧力制御 0.3~4.5MPaの坑口圧力変動に対応 *「18ヶ月で3台のコンプレッサーが酸欠ガスにやられました。KEEPWINのユニットは、腐食ゼロで16,000時間以上稼働しています」* - PetroChina Field Supervisor, Tarim Basin Xinjiang Case: Turning Flare Gas [...] *「腐食ゼロで16,000時間以上稼働しています。

BOG回収コンプレッサーがLNGターミナルの損失を40%削減?

毎年、LNGターミナルでは、貯蔵と移送中のボイルオフガス(BOG)の蒸発により、$220万ドルの損失が発生しています。従来のピストンコンプレッサーは、頻繁な始動停止サイクルや潤滑油の汚染により、これを悪化させています。ここでは、次世代BOG回収技術がどのようにこれらの問題に取り組んでいるかを、稼働中のターミナルからの実データをもとに紹介します。革新の核心磁気ベアリング+VFD制御 KEEPWINのソリューションは2つの画期的な技術を統合しています:アクティブ磁気ベアリング オイル汚染を排除 → 炭化水素排出ゼロ メンテナンスのダウンタイムを年間200時間削減 AI駆動の可変周波数ドライブ(VFD) リアルタイムのBOG量に合わせてコンプレッサー速度を調整 低負荷時のエネルギー浪費を35%削減 「従来のユニットは、アイドルサイクル中に30%の余分な電力を消費していました。当社のシステムは不要な時はスリープします。"- ブシェールプロジェクト、KEEPWINエンジニアリングリード