関連ガスフレアガスやケーシングヘッドガスとしても知られる天然ガスは、原油採掘の際に発生する天然の副産物である。原油が地表に出ると、原油に溶けていた天然ガスも放出される。多くの場合、インフラや処理能力がないため、このガスはフレアガスとして焼却される。

しかし、適切な ガス圧縮回収関連ガスは、廃棄物から燃料に転換することができる。 貴重な燃料または原料エネルギー持続可能性の目標と規制遵守をサポートする。

| 流量 | 1250Nm³/h(標準状態) |

| 吸引圧力 | 0.5Mpa(G) |

| 吐出圧力 | 40.0Mpa(G) |

| 放電温度 | ≤130°C (アフタークーラーなし) |

| モーター・パワー | 280KW |

| 冷却方法 | 空冷式(水が不要) |

| 保護等級 | IP55/クラスF |

| 構造 | ダブルV型空冷ピストン往復圧縮機 |

| サイズと重量 | 9000*2500*2600mm/16600kg |

| 騒音レベル | ≤85 dB(A) |

一度圧縮され処理された随伴ガスは、さまざまな産業で利用されている:

| アプリケーションエリア | 使用例 |

|---|---|

| 石油・ガス | 再圧入、ガスリフト、フレアガス回収 |

| 発電 | オンサイト・ガス・エンジンまたはタービン |

| 石油化学 | 水素または合成ガス製造用原料 |

| CNG/LNGシステム | 圧縮/液化ガスへの転換 |

| 環境コンプライアンス | フレアの最小化とカーボンフットプリントの削減 |

関連ガスには 複合炭化水素-メタン、エタン、プロパン、ブタン、ペンタンなど。 非炭化水素不純物 CO₂、窒素、H₂S、ヘリウムのように。

専用設計 関連ガス圧縮機 には次のような利点がある:

✅ 多成分ガスストリームに対応

のために設計された。 可変圧力と可変流量

✅ 確実にする 漏れのないオイルフリーコンプレッション

✅ サポート 高アンビエント そして リモートフィールド 操作

✅ 有効にする エネルギー回収 フレアガスから

南東部の油田で トルコある上流エネルギー会社は、大量の燃料の供給という繰り返し発生する問題に直面していた。 随伴ガス は、圧縮インフラが不十分であったためにフレアしていた。そのため 環境罰則 しかし、貴重なエネルギー資源を浪費することにもなった。

顧客の目標は、炭化水素を豊富に含むこのフレアガスを回収し、圧縮することであった。 自家発電 そして ガス再注入.

これを実現するためには、高度にカスタマイズされたコンプレッサーソリューションが必要でした。 複雑なガス組成 で 最大40 MPa (400 bar)までの極端な吐出圧力.

ガスの組成複雑で厳しい

ガスの組成複雑で厳しいこのプロジェクトの随伴ガスは、典型的なものであった。 多成分炭化水素ストリームで構成されている:

メタン (CH₄):73.01%

エタン (C₂H₆):9.9%

プロパン (C₃H₈):9.2%

ブタン、ペンタン、ヘキサン (C₄-C₆):~4%

窒素(N₂):0.96%

微量酸素(O₂ < 0.005%)

この混合物は、以下の点でユニークな課題をもたらした。 変動率, 圧力管理そして 潤滑の安全性.

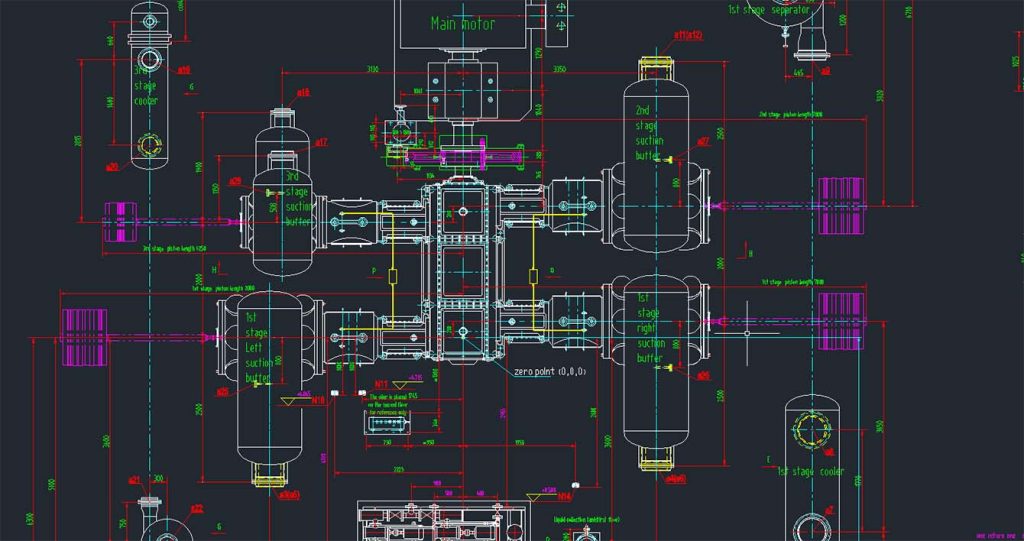

キープウィンのソリューションモデル2VF-3.6/5-400

キープウィンのソリューションモデル2VF-3.6/5-400こうした技術的な要求に応えるためだ、 キープウィンテクノロジー河北有限公司 フルカスタマイズのダブルV-型空冷式5段レシプロコンプレッサーモデル 2VF-3.6/5-400からのガスを圧縮することができる。 0.5 MPa (g) への 40 MPa (g).

主な仕様

主な仕様| 項目 | 価値 |

|---|---|

| 容量フロー | 1250 Nm³/時(3.6 m³/分) |

| 圧縮段階 | 5 |

| 冷却タイプ | 空冷式(水は不要) |

| 潤滑 | シャフトオイル+シリンダーオイルインジェクション |

| 放電温度 | ≤160°C |

| モーター・パワー | 280 kW、dIIBT4、防爆仕様 |

| 駆動方式 | 弾性直接結合 |

| 開始方法 | ソフトスタート |

| 制御システム | PLC + トランスミッター + タッチスクリーン |

| フットプリント | 9000×2500×2600 mm |

| 重量 | 16,600キロ |

ターンキー・スコープの提供

ターンキー・スコープの提供コンプレッサースキッドに加え、Keepwinは以下を提供した:

PLC防爆制御盤

クーラー+軸流ファン冷却システム

バッファータンクとバルブパイプライン

オイルインジェクション+汚水システム

ガス漏れ検知+安全アラーム

照明+環境ヒーター付きキャビンカバー

フルアクセサリーキット:ランダムスペアパーツ、ツール、マニュアル

このターンキー・デザインにより、顧客は以下のことが可能になった。 素早く統合する現場での改造は最小限で済む。

結果とインパクト

結果とインパクト試運転後、このシステムはクライアントに次のことを可能にした:

を 2VF-3.6/5-400 ユニットは、標準的なメンテナンスだけで、6,000時間以上にわたって確実に作動している。

| 特徴 | キープウィン・アドバンテージ |

|---|---|

| ✅ オイルフリー・テクノロジー | ガスの混入がなく、油の分離が不要 |

| ✅ モジュラー、カスタム設計 | 流量、圧力、組成の仕様に合わせて構築 |

| ✅ 現場で実証された性能 | 中東・中央アジアを含む35カ国以上で事業展開 |

| ✅ ヘビーデューティー・エンジニアリング | 鍛造クランクシャフト、防錆コーティング、クラスB/Fモーター |

| ✅ 40年以上の技術的専門知識 | 社内研究開発、機械加工、フルシステムインテグレーション |

| ✅ 迅速な配達 | 標準ユニットは45-60営業日で準備可能 |

ガスリフトシステムの開発、フレアリング排出の最小化、オンサイトエンジンの動力源など、Keepwinは以下を提供します。 エンド・ツー・エンドの圧縮ソリューション 最も複雑な関連ガスの流れに対応する。

📩 お問い合わせ で keepwin@keep-win.com

🌐 訪問: www.keep-win.com

📞 相談する 技術的なアドバイスや3Dレイアウトのご提案については、当社のエンジニアにご相談ください。

世界中のメーカーがコンプレッサのトップメーカーとしてKeepwinを選ぶのには理由があります。産業用製造からエネルギー産業用まで、当社のシステムは20年以上にわたって100を超える国や地域で信頼されています。

お客様の業界を新たな高みへと導く準備はできていますか?Keepwinがガスコンプレッサで選ばれる理由をご覧ください。

ISO9001 ISO14001の標準として製造される。CE TUV ASME等の証明書を取得しました。

39年にわたりコンプレッサーの設計に携わってきた経験豊富なエンジニア

設計から設置まで、当社のコンプレッサー・ソリューションはお客様の時間と労力を節約します。

約22年にわたる経験が生かされている。

長年にわたり、Keepwinは高性能コンプレッサのトップメーカーとして、さまざまな業界にサービスを提供してきました。広範な研究開発の専門知識により、お客様の特定のニーズを満たすカスタム設計ソリューションを提供できます。販売代理店のグローバルネットワークは、信頼性の高いアフターサービスを提供し、お客様の業務が円滑に行われるようにします。

お客様のニーズと敷地条件に基づいた正確な計算と設計

原材料を購入し、部品を鍛造し、コンプレッサーを組み立てる。

窒素条件下で4時間の工場テストを実施

コンプレッサーを納入し、現地で試運転を行います。

最も正確なコンプレッサー設計がすぐに得られます。

お客様のニーズに合ったソリューションを設計するプロのエンジニアを手配いたします。

*お客様のプライバシーを尊重いたします。ご送信いただきましたら、Keepwinのスペシャリストが折り返しご連絡いたします。