酸素(O₂)は無色無臭の気体で、生命と産業に不可欠なものである。地球の大気中で2番目に豊富な元素である酸素は、人間の呼吸だけでなく、燃焼、化学反応、さまざまな製造プロセスにも不可欠である。その反応性の高さから多くの分野で重宝されているが、高圧下での貯蔵や取り扱いには安全上の課題もある。

化学反応性があるからだ、 酸素は専用の装置で圧縮する必要がある コンタミネーションやオーバーヒート、爆発の危険を避けるためだ。そこで 酸素コンプレッサー-特にオイルフリーとダイヤフラムタイプが活躍する。

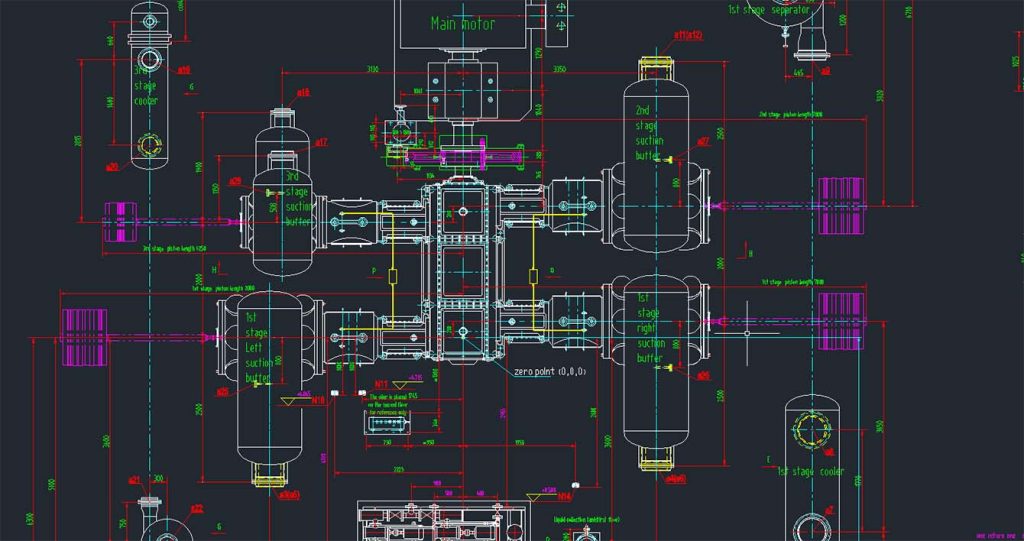

モデル:GV-5/4-150

流量:5Nm³/h(標準条件:0℃、1気圧)

入口圧力:4バール(カスタマイズ可能範囲:3~8バール)

吐出圧力:150バール(超高圧ニーズには最大3200バール)

圧縮段階2段階最適化設計

ドライブオプション:可変速電動モーター

冷却システム:空冷+段間水冷(熱安定性を確保)

制御システム:インテリジェントPLC + HMI (圧力、温度、振動のリアルタイムモニタリング)

圧縮酸素は以下の産業で不可欠である:

医療・ヘルスケア

酸素療法

呼吸器サポート

緊急ボンベ充填

金属と溶接

酸素燃料による切断および溶接

鉄鋼業における高炉

化学処理

酸化反応

リアクター供給ガス

航空宇宙

キャビン加圧および生命維持システム

環境と水処理

浄化のためのオゾン発生

それぞれの用途においてだ、 高純度 そして 安全性 そのため、適切なタイプの酸素コンプレッサーを選ぶことが重要です。

これらのコンプレッサーは、高純度用途に広く使用されています。ダイヤフラム設計により、コンプレッサーの可動部品から酸素が分離され、ガスが油や金属表面に接触することがありません。

メリット

汚染ゼロ

純度99.999%に最適

小流量から中流量に最適

大流量と高圧シリンダー充填に適したオイルフリーピストンコンプレッサーは、頑丈でメンテナンスが比較的簡単です。

メリット

高い吐出圧力(最大300 bar)

長期連続運転への信頼性

ダイアフラムモデルよりも大容量でコスト効率に優れる

スクロールコンプレッサーは、低圧で静かな運転が求められる医療センターでよく見られます。

メリット

静かでコンパクト

歯科および臨床現場に最適

低メンテナンス

2024年、大手産業ガス販売会社 フィリピン の信頼できるソリューションを求めてKEEPWINに依頼した。 PSAジェネレーターからの高純度酸素を貯蔵用ボンベに圧縮する。.このクライアントは、屋内設置用の安全でクリーン、かつコンパクトなユニットを探していた。

綿密な技術コンサルティングの結果、当社のエンジニアは次のようなものを推奨しました。 GV-5/4-150ダイヤフラムコンプレッサー.

モデル GV-5/4-150

流量: 5 Nm³/h

入口圧力: 0.4MPa(PSA酸素発生装置より)

吐出圧力: 15 MPa (150 bar)

デザインタイプ: V型振動板構造

冷却システム 放熱性を高める水冷式

酸素純度サポート: ≥ 99.5%

100% オイルフリー運転

ステンレス製接液部品(316L)

デュアルセーフティリリーフバルブ

自動停止/起動機能付きPLCベース制御

ユニットが出荷され、設置されたのは ケソン市そこでPSAジェネレーターと縦型酸素ボンベ・マニホールドが統合された。

設置時間: 3日間

最初のアウトプット: 25本/日

エネルギー効率: 従来のピストンシステムと比較して消費電力を削減

クライアントのフィードバック

「GV-5/4-150は静かに安全に走行します。GV-5/4-150は静かに安全に作動します。エンジニアリングとKeepwinの技術チームのサポートに感心しています。私たちのPSAシステムに完璧にマッチしました。"

顧客はその後、セブとダバオにある別の病院用に2台のコンプレッサーを追加発注した。

KEEPWIN酸素コンプレッサを選ぶ理由

KEEPWIN酸素コンプレッサを選ぶ理由KEEPWINの専門分野 特注ガス圧縮機 医療用、産業用、エネルギー用23年以上にわたる専門知識により、東南アジア、中東、東欧全域の病院、政府機関、民間企業にソリューションを提供してきました。

ISO9001 認定製造工場

100% オイルフリーコンプレッサーライン

酸素の安全性に関する技術的専門知識

迅速な納品と信頼できるアフターサービス

PSA/O₂ プロジェクトにおける実績

酸素は生命と産業の両方に不可欠な資源です。しかし、酸素を安全に圧縮するには、純度と安全性を考慮して設計された特殊な装置が必要です。医療用ボンベに酸素を充填する場合でも、工業プロセス用に酸素を供給する場合でも ダイヤフラム式酸素コンプレッサー のように GV-5/4-150 妥協のないパフォーマンスを保証する。

KEEPWINでは、コンプレッサーの販売だけでなく、以下のようなエンジニアリングも行っています。 信頼と信用 私たちが製造するすべてのユニットに。

お客様の施設に合わせた酸素圧縮ソリューションにご興味をお持ちですか?

当社の専門家にお問い合わせいただくか、当社のウェブサイトをご覧ください。 酸素コンプレッサー そして オイルフリー圧縮システム. お問い合わせ

世界中のメーカーがコンプレッサのトップメーカーとしてKeepwinを選ぶのには理由があります。産業用製造からエネルギー産業用まで、当社のシステムは20年以上にわたって100を超える国や地域で信頼されています。

お客様の業界を新たな高みへと導く準備はできていますか?Keepwinがガスコンプレッサで選ばれる理由をご覧ください。

ISO9001 ISO14001の標準として製造される。CE TUV ASME等の証明書を取得しました。

39年にわたりコンプレッサーの設計に携わってきた経験豊富なエンジニア

設計から設置まで、当社のコンプレッサー・ソリューションはお客様の時間と労力を節約します。

約22年にわたる経験が生かされている。

長年にわたり、Keepwinは高性能コンプレッサのトップメーカーとして、さまざまな業界にサービスを提供してきました。広範な研究開発の専門知識により、お客様の特定のニーズを満たすカスタム設計ソリューションを提供できます。販売代理店のグローバルネットワークは、信頼性の高いアフターサービスを提供し、お客様の業務が円滑に行われるようにします。

お客様のニーズと敷地条件に基づいた正確な計算と設計

原材料を購入し、部品を鍛造し、コンプレッサーを組み立てる。

窒素条件下で4時間の工場テストを実施

コンプレッサーを納入し、現地で試運転を行います。

最も正確なコンプレッサー設計がすぐに得られます。

お客様のニーズに合ったソリューションを設計するプロのエンジニアを手配いたします。

*お客様のプライバシーを尊重いたします。ご送信いただきましたら、Keepwinのスペシャリストが折り返しご連絡いたします。