Oxygen (O₂) is a colorless, odorless gas that is essential to life and industry. As the second most abundant element in the Earth’s atmosphere, oxygen is critical not only for human respiration but also for combustion, chemical reactions, and various manufacturing processes. Its highly reactive nature makes it valuable across many sectors—but also introduces safety challenges when storing and handling it under high pressure.

Because of its chemical reactivity, oxygen must be compressed using specialized equipment that avoids contamination, overheating, or the risk of explosion. That’s where oxygen compressors—especially oil-free and diaphragm types—come into play.

Modello: GV-5/4-150

Portata del flusso: 5Nm³/h (Standard conditions: 0°C, 1 atm)

Pressione di ingresso: 4 bar (Customizable range: 3–8 bar)

Pressione di scarico: 150 bar (Max. 3200 bar for ultra-high-pressure needs)

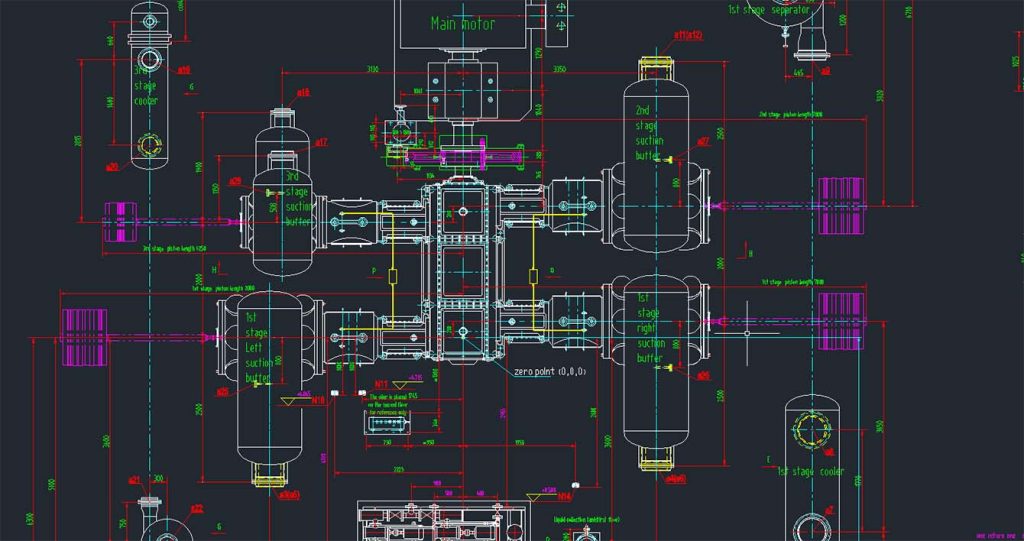

Fasi di compressione: 2-stage optimized design

Opzioni di guida: Variable-speed electric motor

Sistema di raffreddamento: Raffreddamento ad aria + acqua interstage (assicura la stabilità termica)

Sistema di controllo: PLC intelligente + HMI (monitoraggio in tempo reale della pressione, della temperatura e delle vibrazioni).

Compressed oxygen is indispensable in the following industries:

Medical and Healthcare

Oxygen therapy

Respiratory support

Emergency cylinder filling

Metal and Welding

Oxy-fuel cutting and welding

Blast furnaces in steel manufacturing

Trattamento chimico

Oxidation reactions

Reactor feed gas

Aerospace and Aviation

Cabin pressurization and life-support systems

Environmental and Water Treatment

Ozone generation for purification

In each of these applications, high purity e sicurezza are paramount, which is why selecting the right type of oxygen compressor is critical.

These compressors are widely used for high-purity applications. The diaphragm design separates the oxygen from the compressor’s moving parts, ensuring that the gas never comes in contact with oil or metal surfaces.

Vantaggi:

Zero contamination

Ideal for 99.999% purity

Adatto per portate medio-piccole

Well-suited for larger flow rates and high-pressure cylinder filling, oil-free piston compressors are rugged and relatively simple to maintain.

Vantaggi:

High discharge pressure (up to 300 bar)

Reliable for long-term, continuous operation

More cost-effective than diaphragm models for large volumes

Scroll compressors are commonly found in medical centers where lower pressures and quiet operation are needed.

Vantaggi:

Quiet and compact

Ideal for dental and clinical settings

Low maintenance

In 2024, a leading industrial gas distributor in the Philippines reached out to KEEPWIN for a reliable solution to compress high-purity oxygen from a PSA generator into storage cylinders. The client was looking for a safe, clean, and compact unit for indoor installation.

After an in-depth technical consultation, our engineers recommended the GV-5/4-150 diaphragm compressor.

Model: GV-5/4-150

Portata: 5 Nm³/h

Pressione di ingresso: 0.4 MPa (from PSA oxygen generator)

Pressione di scarico: 15 MPa (150 bar)

Design Type: V-type diaphragm structure

Sistema di raffreddamento: Water-cooled for enhanced heat dissipation

Oxygen Purity Support: ≥ 99.5%

100% Oil-Free Operation

Stainless Steel Wetted Parts (316L)

Dual Safety Relief Valves

PLC-Based Control with Auto Stop/Start Functions

The unit was shipped and installed in Quezon City, where it was integrated with a PSA generator and a vertical oxygen cylinder manifold.

Installation Time: 3 Days

Initial Output: 25 cylinders/day

Efficienza energetica: Reduced power consumption compared to legacy piston systems

Client Feedback:

“The GV-5/4-150 runs quietly and safely. We are impressed with the engineering and the support from Keepwin’s technical team. It was the perfect match for our PSA system.”

The client has since ordered two additional compressors for separate hospitals in Cebu and Davao.

Why Choose KEEPWIN Oxygen Compressors?

Why Choose KEEPWIN Oxygen Compressors?KEEPWIN specializes in custom-engineered gas compressors for medical, industrial, and energy applications. With over 23 years of expertise, we have delivered solutions to hospitals, government agencies, and private industries across Southeast Asia, the Middle East, and Eastern Europe.

✅ ISO9001-Certified Manufacturing

✅ 100% Oil-Free Compressor Line

✅ Technical Expertise in Oxygen Safety

✅ Fast Delivery and Reliable After-Sales Service

✅ Proven Track Record with PSA/O₂ Projects

Oxygen is a vital resource for both life and industry. But compressing oxygen safely requires specialized equipment designed with purity and safety in mind. Whether you’re filling medical cylinders or supplying oxygen for industrial processes, a diaphragm oxygen compressor like the GV-5/4-150 ensures performance without compromise.

At KEEPWIN, we don’t just sell compressors—we engineer trust and reliability into every unit we build.

Interested in a tailored oxygen compression solution for your facility?

Contact our experts or visit our website to learn more about our full line of oxygen compressors e oil-free compression systems. Contatti

C'è un motivo per cui i produttori di tutto il mondo si rivolgono a Keepwin come il miglior produttore di compressori. Dall'industria manifatturiera all'industria energetica e tutto il resto, i nostri sistemi sono affidabili in oltre 100 Paesi e regioni da oltre 20 anni.

È pronto a portare il suo settore a nuovi livelli? Continui a leggere per scoprire cosa rende Keepwin la scelta ideale per i compressori di gas.

Prodotto secondo lo standard ISO9001 ISO14001. Certificato CE TUV ASMI ecc.

Ingegnere di grande esperienza, con 39 anni di vasta esperienza nella progettazione di compressori.

Dalla progettazione all'installazione, la nostra soluzione di compressori le fa risparmiare tempo e fatica.

beneficiando di quasi 22 anni di esperienza.

Da anni, Keepwin è un produttore leader di compressori ad alte prestazioni, al servizio di una vasta gamma di settori industriali. Grazie alla nostra vasta esperienza nel campo della ricerca e sviluppo, possiamo fornire soluzioni personalizzate per soddisfare le sue esigenze specifiche. La nostra rete globale di distributori offre un'affidabile assistenza post-vendita, per garantire che le sue operazioni si svolgano senza problemi.

Calcoli e progettazione precisi, basati sulle sue esigenze e sulle condizioni del sito.

Acquistare le materie prime, forgiare i componenti e assemblare il compressore.

Viene sottoposto a un test di fabbrica di 4 ore in condizioni di azoto.

Consegniamo il compressore alla sua sede e forniamo la messa in servizio in loco.

Ottiene il design del compressore più accurato in pochissimo tempo.

Un ingegnere professionista progetterà una soluzione adatta alle vostre esigenze.

*Rispettiamo la sua privacy. Dopo aver inviato la richiesta, i nostri specialisti Keepwin si metteranno in contatto con lei il prima possibile.