Gas associatoIl gas naturale, noto anche come gas di torcia o gas di testa, è un sottoprodotto naturale dell'estrazione del petrolio greggio. Quando il petrolio viene portato in superficie, viene rilasciato anche il gas naturale disciolto nel petrolio. In molti casi, questo gas viene bruciato a causa della mancanza di infrastrutture o di capacità di trattamento.

Tuttavia, con un'adeguata compressione e recupero del gas, il gas associato può essere trasformato da rifiuto in un combustibile o materia prima di valorea sostegno degli obiettivi di sostenibilità energetica e della conformità alle normative.

| Portata del flusso | 1250 Nm³/h (condizioni standard) |

| Pressione di aspirazione | 0,5Mpa(G) |

| Pressione di scarico | 40,0Mpa(G) |

| Temperatura di scarico. | ≤130°C (senza post-refrigeratore) |

| Potenza del motore | 280KW |

| Metodo di raffreddamento | Raffreddato ad aria (non è necessaria l'acqua) |

| Classe di protezione | IP55 / Classe F |

| Struttura | Compressore a pistoni alternativi di tipo a doppia V, raffreddato ad aria |

| Dimensioni e peso | 9000*2500*2600mm/16600kg |

| Livello di rumore | ≤85 dB(A) |

Il gas associato, una volta compresso e trattato, trova applicazione in diversi settori industriali:

| Area di applicazione | Esempio di caso d'uso |

|---|---|

| Petrolio e gas | Reiniezione, sollevamento del gas, recupero del gas di torcia |

| Generazione di energia | Motori o turbine a gas in loco |

| Petrolchimico | Materia prima per la produzione di idrogeno o di syngas |

| Sistemi CNG / LNG | Conversione in gas compresso/liquefatto |

| Conformità ambientale | Minimizzazione della torcia e riduzione dell'impronta di carbonio |

Il gas associato contiene un miscela complessa di idrocarburi-come il metano, l'etano, il propano, il butano e il pentano, oltre a impurità non idrocarburiche come CO₂, azoto, H₂S ed elio.

Una struttura ad hoc compressore di gas associato offre i seguenti vantaggi:

✅ Gestisce flussi di gas multicomponente

✅ Progettato per pressione e flusso variabili

Assicura compressione senza perdite e senza olio

✅ Supporta ambiente elevato e campo remoto operazione

✅ Abilita recupero di energia da gas di torcia

Nei giacimenti di petrolio del sud-est TurchiaUn'azienda energetica upstream si è trovata ad affrontare un problema ricorrente: grandi volumi di gas associato a causa dell'insufficienza dell'infrastruttura di compressione. Questo non solo ha causato sanzioni ambientali ma anche lo spreco di preziose risorse energetiche.

L'obiettivo del cliente era quello di recuperare e comprimere questo gas di torcia ricco di idrocarburi per generazione di energia in loco e reiniezione del gas.

Per raggiungere questo obiettivo, è stata richiesta una soluzione di compressione altamente personalizzata in grado di gestire composizioni di gas complesse a pressioni di scarico estreme fino a 40 MPa (400 bar).

Composizione del gas: Complesso e impegnativo

Composizione del gas: Complesso e impegnativoIl gas associato in questo progetto era un tipico flusso di idrocarburi multicomponente, che consiste principalmente in:

Metano (CH₄): 73.01%

Etano (C₂H₆): 9,9%

Propano (C₃H₈): 9.2%

Butani, pentani, esani (C₄-C₆): ~4%

Azoto (N₂): 0,96%

Ossigeno in tracce (O₂ < 0,005%)

Questa miscela ha presentato sfide uniche in termini di volatilità, gestione della pressione, e sicurezza della lubrificazione.

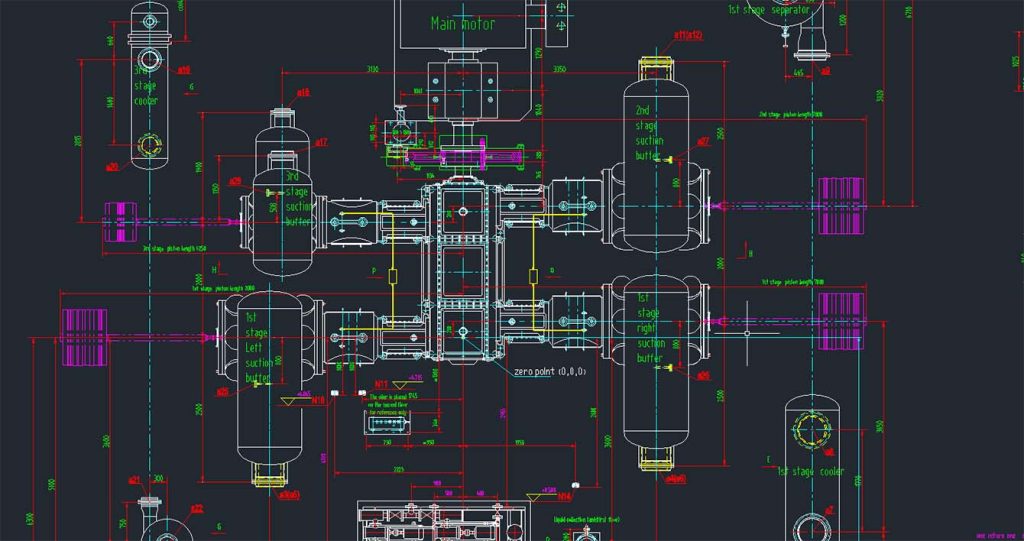

La soluzione di Keepwin: Modello 2VF-3.6/5-400

La soluzione di Keepwin: Modello 2VF-3.6/5-400Per soddisfare queste esigenze tecniche, Keepwin Technology Hebei Co., Ltd. ha consegnato un doppio V completamente personalizzato-Compressore alternativo a 5 stadi, raffreddato ad aria., modello 2VF-3.6/5-400in grado di comprimere il gas da 0,5 MPa (g) a 40 MPa (g).

Specifiche principali:

Specifiche principali:| Articolo | Valore |

|---|---|

| Capacità Flusso | 1250 Nm³/h (3,6 m³/min) |

| Fasi di compressione | 5 |

| Tipo di raffreddamento | Raffreddato ad aria (non richiede acqua) |

| Lubrificazione | Iniezione di olio per alberi + olio per cilindri |

| Temperatura di scarico | ≤160°C |

| Potenza del motore | 280 kW, dIIBT4, antideflagrante |

| Sistema di azionamento | Accoppiamento diretto elastico |

| Metodo di avvio | Avvio graduale |

| Sistema di controllo | PLC + trasmettitore + touchscreen |

| Impronta | 9000×2500×2600 mm |

| Peso | 16.600 kg |

Ambito di applicazione "chiavi in mano

Ambito di applicazione "chiavi in manoOltre allo skid per il compressore, Keepwin ha fornito anche il sistema di controllo della temperatura:

Armadio di controllo antideflagrante con PLC

Raffreddatore + sistema di raffreddamento a ventola assiale

Serbatoio tampone e tubazione della valvola

Iniezione di olio + sistema fognario

Rilevamento di fughe di gas + allarmi di sicurezza

Copertura della cabina con illuminazione + riscaldamento ambientale

Kit completo di accessori: ricambi casuali, utensili, manuali

Questo progetto chiavi in mano ha permesso al cliente di integrarsi rapidamentecon minime modifiche in loco.

Risultati e impatto

Risultati e impattoDopo la messa in funzione, il sistema ha consentito al cliente di:

Il 2VF-3.6/5-400 ha funzionato in modo affidabile per oltre 6.000 ore con una manutenzione standard.

| Caratteristica | Vantaggio Keepwin |

|---|---|

| ✅ Tecnologia senza olio | Nessuna contaminazione da gas, nessuna separazione dell'olio |

| ✅ Modulare, design personalizzato | Costruito secondo le specifiche di portata, pressione e composizione |

| ✅ Prestazioni comprovate sul campo | Presente in oltre 35 paesi, tra cui Medio Oriente e Asia Centrale |

| ✅ Ingegneria dei mezzi pesanti | Albero motore forgiato, rivestimenti anticorrosione, motori di classe B/F |

| ✅ Oltre 40 anni di esperienza tecnica | Ricerca e sviluppo, lavorazione e integrazione completa del sistema in-house |

| ✅ Consegna rapida | Unità standard pronte in 45-60 giorni lavorativi |

Sia che si tratti di sviluppare un sistema di sollevamento del gas, di ridurre al minimo le emissioni di flaring o di alimentare motori in loco, Keepwin fornisce Soluzioni di compressione end-to-end per i flussi di gas associati più complessi.

📩 Ci contatti a keepwin@keep-win.com

🌐 Visita: www.keep-win.com

📞 Consultare i nostri ingegneri per consulenze tecniche o proposte di layout 3D.

C'è un motivo per cui i produttori di tutto il mondo si rivolgono a Keepwin come il miglior produttore di compressori. Dall'industria manifatturiera all'industria energetica e tutto il resto, i nostri sistemi sono affidabili in oltre 100 Paesi e regioni da oltre 20 anni.

È pronto a portare il suo settore a nuovi livelli? Continui a leggere per scoprire cosa rende Keepwin la scelta ideale per i compressori di gas.

Prodotto secondo lo standard ISO9001 ISO14001. Certificato CE TUV ASME ecc.

Ingegnere di grande esperienza, con 39 anni di vasta esperienza nella progettazione di compressori.

Dalla progettazione all'installazione, la nostra soluzione di compressori le fa risparmiare tempo e fatica.

beneficiando di quasi 22 anni di esperienza.

Da anni, Keepwin è un produttore leader di compressori ad alte prestazioni, al servizio di una vasta gamma di settori industriali. Grazie alla nostra vasta esperienza nel campo della ricerca e sviluppo, possiamo fornire soluzioni personalizzate per soddisfare le sue esigenze specifiche. La nostra rete globale di distributori offre un'affidabile assistenza post-vendita, per garantire che le sue operazioni si svolgano senza problemi.

Calcoli e progettazione precisi, basati sulle sue esigenze e sulle condizioni del sito.

Acquistare le materie prime, forgiare i componenti e assemblare il compressore.

Viene sottoposto a un test di fabbrica di 4 ore in condizioni di azoto.

Consegniamo il compressore alla sua sede e forniamo la messa in servizio in loco.

Ottiene il design del compressore più accurato in pochissimo tempo.

Un ingegnere professionista progetterà una soluzione adatta alle vostre esigenze.

*Rispettiamo la sua privacy. Dopo aver inviato la richiesta, i nostri specialisti Keepwin si metteranno in contatto con lei il prima possibile.