Negli impianti petrolchimici, le stazioni di compressione sono fondamentali, ma spesso la loro costruzione richiede molto tempo. Compressori modulari montati su skid offrono una soluzione rivoluzionaria: unità preassemblate e testate in fabbrica che riducono drasticamente il lavoro in loco, i rischi di pianificazione e i costi di installazione.

1. Fabbricazione fuori sede = distribuzione più rapida

Costruiti interamente in condizioni controllate di fabbrica, gli skid modulari dei compressori arrivano in loco 80-90% completi: la maggior parte delle saldature, delle tubazioni, dei pannelli di controllo e dei collaudi viene eseguita in anticipo. Questo approccio evita i ritardi dovuti alle condizioni atmosferiche, riduce al minimo le interferenze con le opere civili e permette di costruzione parallelacomprimendo in modo significativo le tempistiche del progetto .

2. Qualità costante e rischio ridotto

I moduli costruiti in fabbrica sono sottoposti a un rigoroso controllo di qualità, che comprende FAT (Test di accettazione in fabbrica)garantendo un funzionamento affidabile prima della spedizione. In questo modo si evitano errori di costruzione in loco, si migliora la conformità ai codici API/ASME e si migliora l'integrità complessiva del sistema. .

3. Riduzione dei costi CAPEX e di installazione

Gli skid modulari riducono al minimo la manodopera sul campo, le impalcature e il supporto in cantiere, consentendo di minori costi di manodopera e civilie minori tempi di inattività delle operazioni esistenti

4. Maggiore flessibilità e scalabilità

Con l'evolversi delle esigenze dell'impianto, è possibile integrare facilmente altri skid di compressori nei sistemi esistenti. Gli skid offrono scalabilità plug-and-playideale per l'espansione graduale o per esigenze temporanee. E se necessario, possono essere riposizionati o riutilizzati, prolungando la durata di vita delle risorse. .

5. Ambiente di assemblaggio più sicuro e controllato

Le officine della fabbrica seguono pratiche di sicurezza rigorose: gru a ponte, laboratori di saldatura controllati e procedure standardizzate. Questo riduce gli incidenti di sicurezza in locosoprattutto negli impianti petrolchimici congestionati .

Confronto tra sistemi di compressione a slitta e sistemi a stelo

| Caratteristica | Sistema Stick-Built | Compressore montato su skid |

|---|---|---|

| Tempo di installazione | Mesi di lavoro in loco | Settimane con configurazione plug-and-play |

| Garanzia di qualità | Variabile e dipendente dal tempo | Testato e certificato in fabbrica |

| Lavori civili e di cantiere | Infrastruttura estesa | Collegamenti e fondamenta minime |

| Scalabilità | Espansioni complesse | Facilmente scalabile con i componenti aggiuntivi modulari |

| Sicurezza e affidabilità | Rischio di campo più elevato | Costruzione di officine più sicure, meno incidenti |

Applicazioni nei progetti petrolchimici

-

Stazioni di iniezione del gas

-

Compressione Booster per linee di alimentazione

-

Ricompressione nelle unità di distillazione sotto vuoto

-

Sistemi di riciclaggio di idrogeno, GPL e CO₂

Tutti beneficiano di skid di compressori modulari che semplificano la messa in servizio e riducono al minimo le interruzioni dell'impianto.

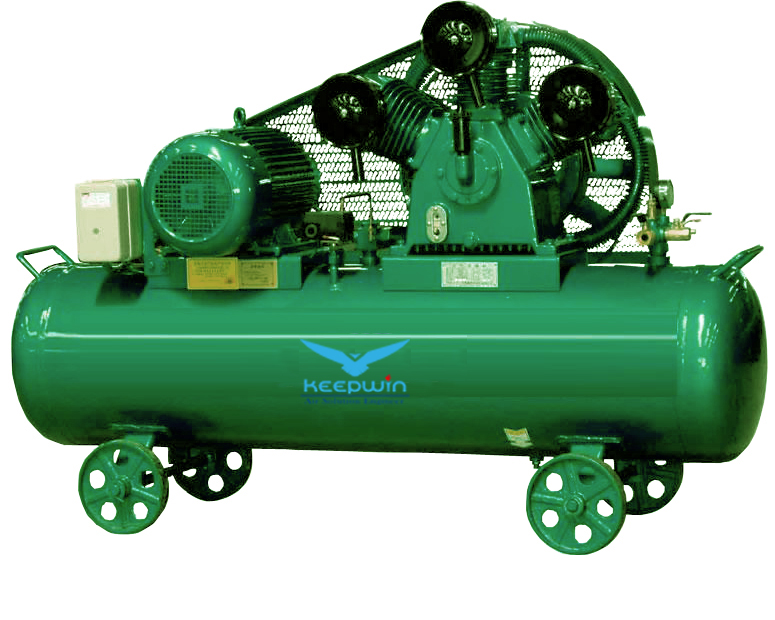

Perché KEEPWIN è leader nel settore

KEEPWIN progetta skid per compressori completamente integrati, completi di:

-

Compressori a vite, alternativi o a membrana

-

Strumentazione e pannello di controllo

-

Filtri, raffreddatori, valvole, smorzatori di pulsazioni

-

Pre-cablaggio e test PLC/SCADA del pannello

I nostri modelli offrono sistemi chiavi in mano, plug-and-play, progettati per un avvio rapido, un'elevata efficienza e una sicurezza di livello petrolchimico.

Conclusione

Nell'ingegneria petrolchimica, tempi, qualità e flessibilità non sono negoziabili. Compressori modulari montati su skid La tecnologia di KEEPWIN è in grado di offrire risultati su tutti i fronti: ridurre le spese di investimento, accelerare le scadenze e migliorare la sicurezza. Con gli skid per compressori personalizzati di KEEPWIN, gli impianti possono accelerare le consegne, semplificare le espansioni e garantire operazioni conformi e ad alte prestazioni.

👉 Siete pronti a velocizzare l'installazione del vostro compressore? Contatto MANTENERE oggi stesso per un pacchetto dettagliato di soluzioni per skid compressor!