For industries handling high-purity or hazardous gases—such as semiconductor manufacturing, specialty chemicals, or hydrogen processing—a leak-tight diaphragm compressor is essential. These compressors isolate the gas from lubrication systems, delivering contamination-free compression with superior sealing performance . Below are nine critical steps to ensure your diaphragm compression system meets the highest leak-tight standards.

9-Step Guide to Leak‑Tight Diaphragm Compression

1. Select API 618 or ISO-Certified Units

Choose compressors that meet API 618 or ISO standards for seal integrity and design reliability. Such units deliver leak rates down to 1×10⁻⁶ cm³/s .

2. Use Multi-Diaphragm, Sealless Designs

Opt for triple-metal or multi-layer diaphragm assemblies. These designs isolate gas, hydraulic fluid, and leak-detect layers—preventing cross-contamination .

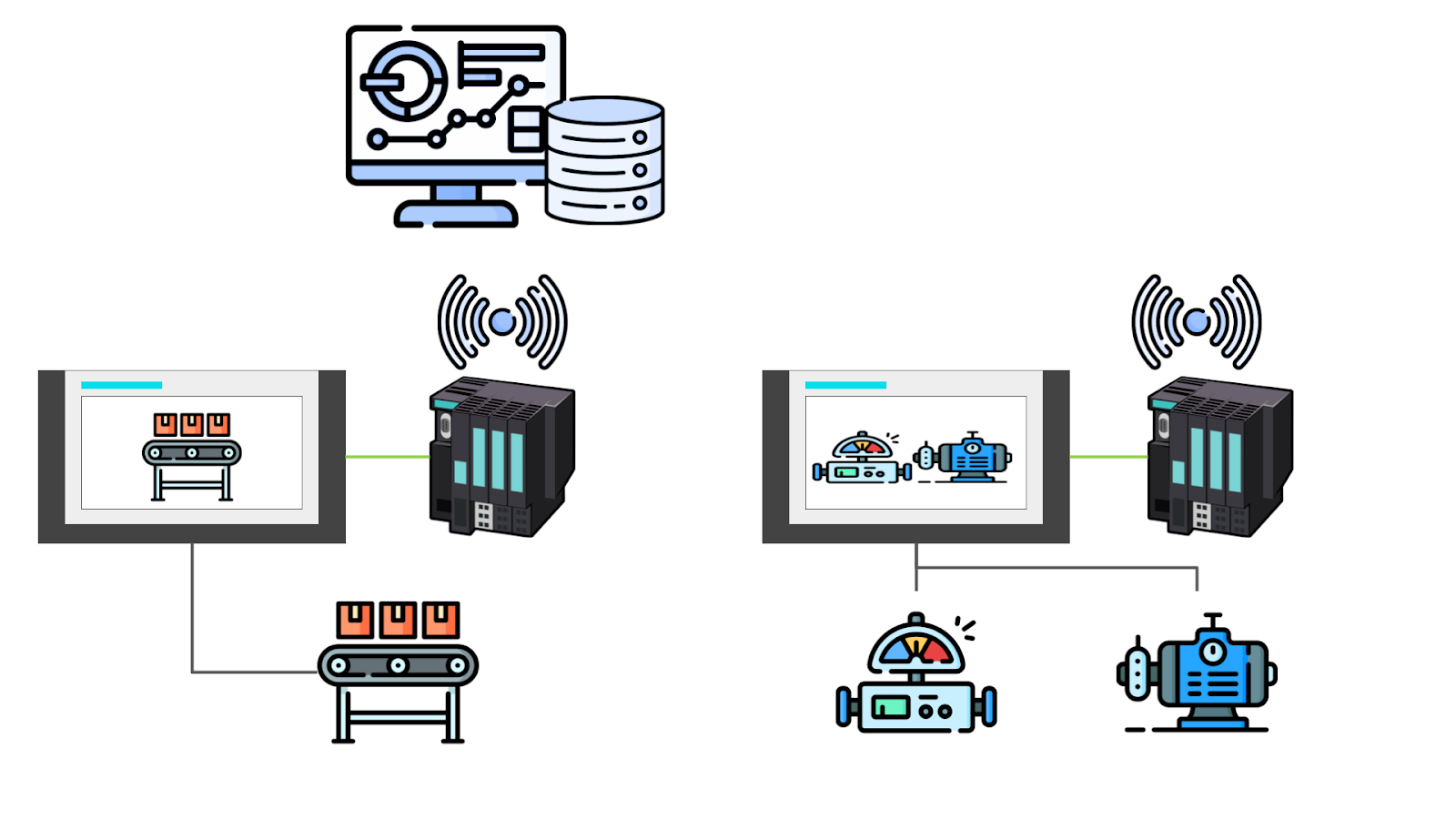

3. Integrate Leak Detection Systems

Install continuous monitoring on gas and hydraulic chambers to detect diaphragm breaches early and trigger alarms or shutdowns .

4. Perform Non‑Destructive Leak Testing

Regularly conduct helium mass spectrometry or bubble tests on diaphragms, valve seats, and static seals to identify micro-leaks before failure .

5. Verify Torque on Clamping Bolts

Ensure bolt tightness on compressor heads is within specified torque limits; improper torque leads to seal failure .

6. Clean & Inspect Mechanical Connections

Regularly inspect and maintain static O-rings, side bars, pipework connections; polymer/metal seals age over time and must be replaced before failure .

7. Ensure Efficient Cooling

Maintain proper coolant temperature to prevent diaphragm overheating and reduce stress on seals .

8. Replace Diaphragms Proactively

Track diaphragm service life (e.g. hours or cycles) and replace before fatigue-driven micro-tears occur.

9. Maintain Detailed Records & Performance Logs

Log maintenance actions, torque checks, pressure readings, leak test results, and any alarms. These support trend analysis and predictive replacements .

Why These Steps Matter

Diaphragm compressors are prized for their exceptional purity and zero oil contamination—critical in applications including toxic/toxic, corrosive, high-purity, or specialty gases . Proper implementation of these nine steps ensures:

-

Leak-tight integrity (<1×10⁻⁶ cm³/s)

-

Reliable containment of hazardous/pure gases

-

Compliance with safety and environmental regulations

-

Optimized compressor uptime and minimal unplanned maintenance

✅ READY‑TO‑DEPLOY SOLUTIONS BY KEEPWIN

For a turnkey solution, KEEPWIN delivers diaphragm compression systems engineered for leak-tight performance:

-

API 618-compliant, multi-diaphragm packages with leak detection

-

Leak-proof dynamic seals and static O-rings

-

Cooling systems designed for optimal temperature control

-

Full documentation for QA/QC and regulatory compliance

Achieving leak-tight diaphragm compression for pure gas starts with certified equipment, rigorous sealing systems, and robust maintenance protocols. By following these nine steps, you can ensure safe, reliable, and contamination-free operation.

👉 Contact KEEPWIN today for a customized diaphragm compressor solution tailored to your gas requirements.