Oxygen (O₂) is a colorless, odorless gas that is essential to life and industry. As the second most abundant element in the Earth’s atmosphere, oxygen is critical not only for human respiration but also for combustion, chemical reactions, and various manufacturing processes. Its highly reactive nature makes it valuable across many sectors—but also introduces safety challenges when storing and handling it under high pressure.

Because of its chemical reactivity, oxygen must be compressed using specialized equipment that avoids contamination, overheating, or the risk of explosion. That’s where oxygen compressors—especially oil-free and diaphragm types—come into play.

Model: GV-5/4-150

Flow Rate: 5Nm³/h (Standard conditions: 0°C, 1 atm)

Inlet Pressure: 4 bar (Customizable range: 3–8 bar)

Discharge Pressure: 150 bar (Max. 3200 bar for ultra-high-pressure needs)

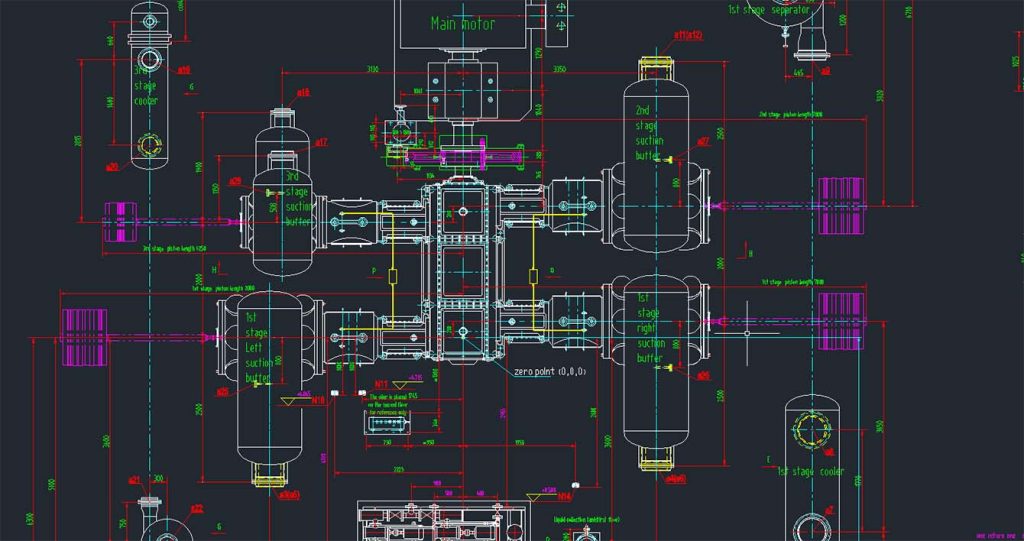

Compression Stages: 2-stage optimized design

Drive Options: Variable-speed electric motor

Cooling System: Air + Interstage water cooling (ensures thermal stability)

Control System: Intelligent PLC + HMI (real-time monitoring of pressure, temperature, vibration)4

Compressed oxygen is indispensable in the following industries:

Medical and Healthcare

Oxygen therapy

Respiratory support

Emergency cylinder filling

Metal and Welding

Oxy-fuel cutting and welding

Blast furnaces in steel manufacturing

Chemical Processing

Oxidation reactions

Reactor feed gas

Aerospace and Aviation

Cabin pressurization and life-support systems

Environmental and Water Treatment

Ozone generation for purification

In each of these applications, high purity and safety are paramount, which is why selecting the right type of oxygen compressor is critical.

These compressors are widely used for high-purity applications. The diaphragm design separates the oxygen from the compressor’s moving parts, ensuring that the gas never comes in contact with oil or metal surfaces.

Advantages:

Zero contamination

Ideal for 99.999% purity

Suitable for small to medium flow rates

Well-suited for larger flow rates and high-pressure cylinder filling, oil-free piston compressors are rugged and relatively simple to maintain.

Advantages:

High discharge pressure (up to 300 bar)

Reliable for long-term, continuous operation

More cost-effective than diaphragm models for large volumes

Scroll compressors are commonly found in medical centers where lower pressures and quiet operation are needed.

Advantages:

Quiet and compact

Ideal for dental and clinical settings

Low maintenance

In 2024, a leading industrial gas distributor in the Philippines reached out to KEEPWIN for a reliable solution to compress high-purity oxygen from a PSA generator into storage cylinders. The client was looking for a safe, clean, and compact unit for indoor installation.

After an in-depth technical consultation, our engineers recommended the GV-5/4-150 diaphragm compressor.

Model: GV-5/4-150

Flow Rate: 5 Nm³/h

Inlet Pressure: 0.4 MPa (from PSA oxygen generator)

Discharge Pressure: 15 MPa (150 bar)

Design Type: V-type diaphragm structure

Cooling System: Water-cooled for enhanced heat dissipation

Oxygen Purity Support: ≥ 99.5%

100% Oil-Free Operation

Stainless Steel Wetted Parts (316L)

Dual Safety Relief Valves

PLC-Based Control with Auto Stop/Start Functions

The unit was shipped and installed in Quezon City, where it was integrated with a PSA generator and a vertical oxygen cylinder manifold.

Installation Time: 3 Days

Initial Output: 25 cylinders/day

Energy Efficiency: Reduced power consumption compared to legacy piston systems

Client Feedback:

“The GV-5/4-150 runs quietly and safely. We are impressed with the engineering and the support from Keepwin’s technical team. It was the perfect match for our PSA system.”

The client has since ordered two additional compressors for separate hospitals in Cebu and Davao.

Why Choose KEEPWIN Oxygen Compressors?

Why Choose KEEPWIN Oxygen Compressors?KEEPWIN specializes in custom-engineered gas compressors for medical, industrial, and energy applications. With over 23 years of expertise, we have delivered solutions to hospitals, government agencies, and private industries across Southeast Asia, the Middle East, and Eastern Europe.

✅ ISO9001-Certified Manufacturing

✅ 100% Oil-Free Compressor Line

✅ Technical Expertise in Oxygen Safety

✅ Fast Delivery and Reliable After-Sales Service

✅ Proven Track Record with PSA/O₂ Projects

Oxygen is a vital resource for both life and industry. But compressing oxygen safely requires specialized equipment designed with purity and safety in mind. Whether you’re filling medical cylinders or supplying oxygen for industrial processes, a diaphragm oxygen compressor like the GV-5/4-150 ensures performance without compromise.

At KEEPWIN, we don’t just sell compressors—we engineer trust and reliability into every unit we build.

Interested in a tailored oxygen compression solution for your facility?

Contact our experts or visit our website to learn more about our full line of oxygen compressors and oil-free compression systems. Contact Us

There’s a reason why manufacturers worldwide turn to Keepwin as the top compressor manufacturer. From industrial manufacturing to energy industrial and everything in between, our systems have been trusted in 100+ countries and regions for 20+ years.

Ready to take your industry to new heights? Continue reading to learn what makes Keepwin the clear choice for gas compressors

Manufactured as ISO9001 ISO14001 standard. Got CE TUV ASME Etc Certificate

Highly experienced engineer with 39 years of extensive compressor design expertise

From design to installation, our compressor solution saves you time and effort.

benefit from almost 22 years of experience.

For years, Keepwin has been a leading manufacturer of high-performance compressors, serving a diverse range of industries. With our extensive R&D expertise, we can provide custom-engineered solutions to meet your specific needs. Our global network of distributors offers reliable after-sales support to ensure your operations run smoothly.

Precise calculations and design based on your needs and site conditions

Buy raw materials, forge components, and assemble the compressor

Undergoes a 4-hour factory test run under nitrogen conditions

Deliver the compressor to your site and provide on-site commissioning.

Get the most accurate compressor design in no time.

We will arrange for a professional engineer to design a solution to suit your needs.

*We respect your privacy. Upon submission, our dedicated Keepwin specialists will get in touch at their soonest availability.