Nitrogen (N₂) is abundant (78% of air), colorless, odorless, and inert.

Key Features:

Applications:

1. Sky-High Energy Costs?

Problem: Traditional compressors waste energy with inefficient compression cycles.

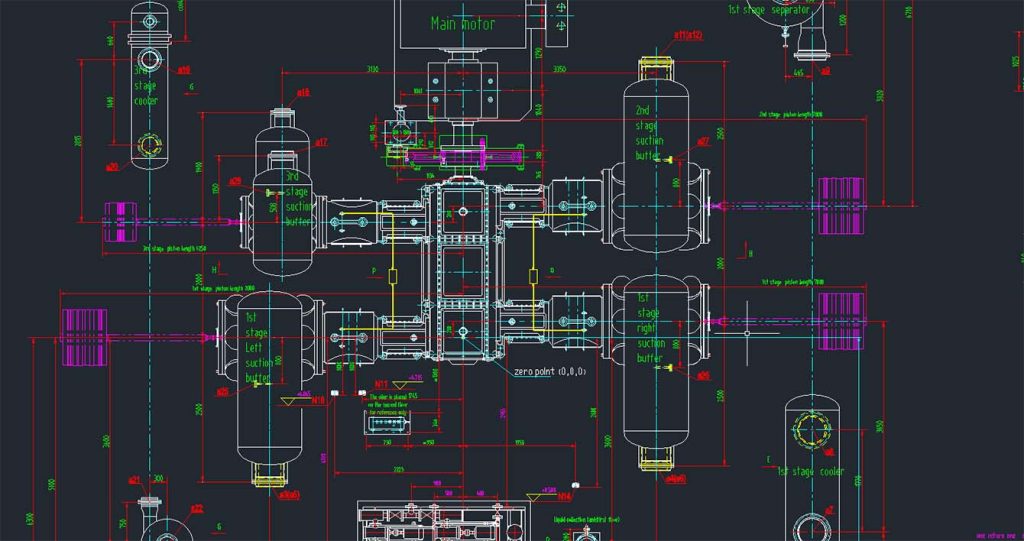

Our Solution: Advanced 4-stage compression with isentropic efficiency up to 85%, reducing energy consumption by 20%.

2. Frequent Downtime from Breakdowns?

Problem: Unstable performance and leaks under extreme pressure.

Our Solution: Forged steel cylinders + alloy-coated pistons ensure zero leakage at 400 bar, backed by vibration sensors and automatic shutdown for overload protection.

3. Costly Maintenance Cycles?

Problem: Complex repairs and frequent part replacements.

Our Solution: Modular design allows 50% faster maintenance, while oil-free technology and self-lubricating bearings extend service intervals to 8,000 hours.

4. Struggling with Variable Gas Demands?

Problem: Rigid compressors can’t adapt to fluctuating workflows.

Our Solution: Variable-speed drive adjusts output in real time, and a 3–8 bar inlet range accommodates unstable gas sources.

Oil & Gas

Pipeline purging, tank inerting, hydraulic fracturing.

Survives harsh environments (dust, humidity, corrosive gases).

Chemicals & Pharmaceuticals

High-purity N₂ supply (≥99.999%) for reaction chambers.

Energy & Aerospace

Fuel cell testing, rocket propulsion systems.

Manufacturing

Laser cutting, high-pressure vessel certification.

Proven Reliability: Over 100 units deployed globally, with a 99.5% uptime track record.

Certified Safety: Compliant with API 618, ATEX/Exd IIB, and PED standards.

Lifetime Support: 24/7 technical assistance, spare parts delivered within 72 hours.

Oil & Gas: 10 compressors installed in a Middle Eastern oil field for pipeline inerting – zero failures in 3 years.

Aerospace: Custom 450 bar system for a European hydrogen lab – enabled 20% faster testing cycles.

There’s a reason why manufacturers worldwide turn to Keepwin as the top compressor manufacturer. From industrial manufacturing to energy industrial and everything in between, our systems have been trusted in 100+ countries and regions for 20+ years.

Ready to take your industry to new heights? Continue reading to learn what makes Keepwin the clear choice for gas compressors

Manufactured as ISO9001 ISO14001 standard. Got CE TUV ASME Etc Certificate

Highly experienced engineer with 39 years of extensive compressor design expertise

From design to installation, our compressor solution saves you time and effort.

benefit from almost 22 years of experience.

For years, Keepwin has been a leading manufacturer of high-performance compressors, serving a diverse range of industries. With our extensive R&D expertise, we can provide custom-engineered solutions to meet your specific needs. Our global network of distributors offers reliable after-sales support to ensure your operations run smoothly.

Precise calculations and design based on your needs and site conditions

Buy raw materials, forge components, and assemble the compressor

Undergoes a 4-hour factory test run under nitrogen conditions

Deliver the compressor to your site and provide on-site commissioning.

Get the most accurate compressor design in no time.

We will arrange for a professional engineer to design a solution to suit your needs.

*We respect your privacy. Upon submission, our dedicated Keepwin specialists will get in touch at their soonest availability.