Associated gas, also known as flare gas or casinghead gas, is a natural byproduct of crude oil extraction. When oil is brought to the surface, natural gas dissolved in the oil is also released. In many cases, this gas is flared—burned off—due to lack of infrastructure or processing capability.

However, with proper gas compression and recovery, associated gas can be transformed from waste into a valuable fuel or feedstock, supporting energy sustainability goals and regulatory compliance.

| Flow Rate | 1250 Nm³/h(standard conditions) |

| Suction Pressure | 0.5Mpa(G) |

| Discharge Pressure | 40.0Mpa(G) |

| Discharge Temp. | ≤130°C (no aftercooler) |

| Motor Power | 280KW |

| Cooling Method | Air-cooled (no water needed) |

| Protection Class | IP55 / Class F |

| Structure | Double V type, Air cooled, Reciprocating Piston Compressor |

| Size & Weight | 9000*2500*2600mm/ 16600kg |

| Noise Level | ≤85 dB(A) |

Associated gas, once compressed and treated, finds application in various industries:

| Application Area | Use Case Example |

|---|---|

| Oil & Gas | Reinjection, gas lift, flare gas recovery |

| Power Generation | On-site gas engines or turbines |

| Petrochemical | Feedstock for hydrogen or syngas production |

| CNG / LNG Systems | Conversion into compressed/liquefied gas |

| Environmental Compliance | Flare minimization and carbon footprint reduction |

Associated gas contains a complex mix of hydrocarbons—such as methane, ethane, propane, butane, pentane—as well as non-hydrocarbon impurities like CO₂, nitrogen, H₂S, and helium.

A purpose-built associated gas compressor offers the following advantages:

✅ Handles multi-component gas streams

✅ Designed for variable pressure and flow

✅ Ensures leak-free, oil-free compression

✅ Supports high ambient and remote field operation

✅ Enables energy recovery from flare gas

In the oilfields of southeastern Turkey, one upstream energy company faced a recurring issue: large volumes of associated gas were being flared due to insufficient compression infrastructure. This not only caused environmental penalties but also wasted valuable energy resources.

The customer’s goal was to recover and compress this flare gas—rich in hydrocarbons—for on-site power generation and gas reinjection.

To achieve this, they required a highly customized compressor solution capable of handling complex gas compositions at extreme discharge pressures up to 40 MPa (400 bar).

Gas Composition: Complex & Demanding

Gas Composition: Complex & DemandingThe associated gas in this project was a typical multicomponent hydrocarbon stream, primarily consisting of:

Methane (CH₄): 73.01%

Ethane (C₂H₆): 9.9%

Propane (C₃H₈): 9.2%

Butanes, Pentanes, Hexanes (C₄–C₆): ~4%

Nitrogen (N₂): 0.96%

Trace Oxygen (O₂ < 0.005%)

This mixture presented unique challenges in terms of volatility, pressure management, and lubrication safety.

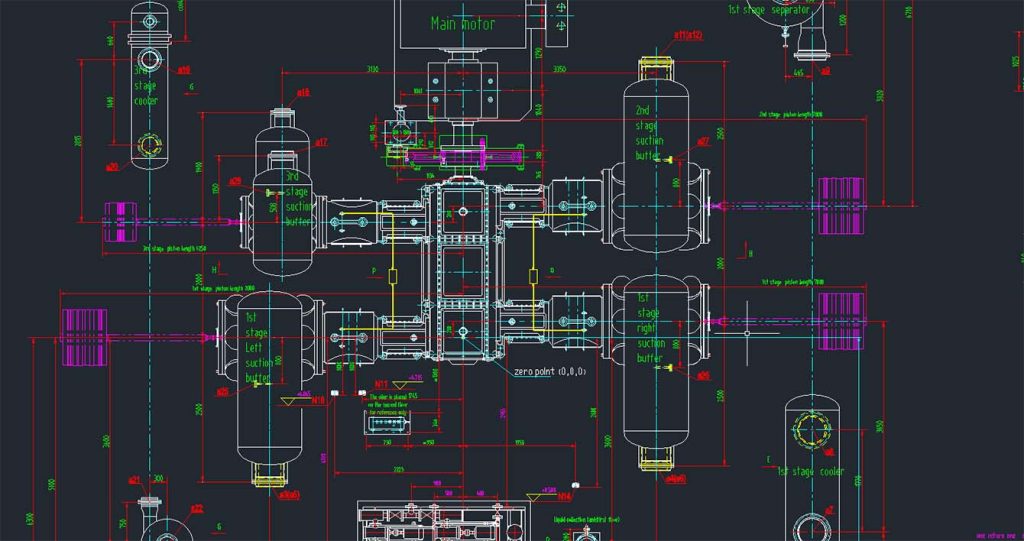

Keepwin’s Solution: Model 2VF-3.6/5-400

Keepwin’s Solution: Model 2VF-3.6/5-400To meet these technical demands, Keepwin Technology Hebei Co., Ltd. delivered a fully customized double V-type 5-stage air-cooled reciprocating compressor, model 2VF-3.6/5-400, capable of compressing gas from 0.5 MPa (g) to 40 MPa (g).

Key Specifications:

Key Specifications:| Item | Value |

|---|---|

| Capacity Flow | 1250 Nm³/h (3.6 m³/min) |

| Compression Stages | 5 |

| Cooling Type | Air-cooled (no water required) |

| Lubrication | Shaft oil + Cylinder oil injection |

| Discharge Temperature | ≤160°C |

| Motor Power | 280 kW, dIIBT4, Explosion-proof |

| Drive System | Elastic direct coupling |

| Start Method | Soft start |

| Control System | PLC + transmitter + touchscreen |

| Footprint | 9000×2500×2600 mm |

| Weight | 16,600 kg |

Turnkey Scope Provided

Turnkey Scope ProvidedIn addition to the compressor skid, Keepwin supplied:

PLC explosion-proof control cabinet

Cooler + axial fan cooling system

Buffer tank and valve pipeline

Oil injection + sewage system

Gas leak detection + safety alarms

Cabin cover with lighting + environmental heating

Full accessory kit: random spare parts, tools, manuals

This turnkey design allowed the customer to integrate quickly, with minimal on-site modification.

Results and Impact

Results and ImpactAfter commissioning, the system enabled the client to:

The 2VF-3.6/5-400 unit has operated reliably for over 6,000 hours with only standard maintenance.

| Feature | Keepwin Advantage |

|---|---|

| ✅ Oil-Free Technology | No gas contamination, no oil separation needed |

| ✅ Modular, Custom Design | Built to spec for flow, pressure, composition |

| ✅ Field-Proven Performance | Operating in >35 countries, incl. Middle East and Central Asia |

| ✅ Heavy-Duty Engineering | Forged crankshaft, anti-corrosion coatings, Class B/F motors |

| ✅ 40+ Years Technical Expertise | In-house R&D, machining, and full-system integration |

| ✅ Fast Delivery | Standard units ready in 45–60 working days |

Whether you’re developing a gas lift system, minimizing flaring emissions, or powering on-site engines—Keepwin provides end-to-end compression solutions for the most complex associated gas streams.

📩 Contact us at keepwin@keep-win.com

🌐 Visit: www.keep-win.com

📞 Consult our engineers for technical advice or 3D layout proposals.

There’s a reason why manufacturers worldwide turn to Keepwin as the top compressor manufacturer. From industrial manufacturing to energy industrial and everything in between, our systems have been trusted in 100+ countries and regions for 20+ years.

Ready to take your industry to new heights? Continue reading to learn what makes Keepwin the clear choice for gas compressors

Manufactured as ISO9001 ISO14001 standard. Got CE TUV ASME Etc Certificate

Highly experienced engineer with 39 years of extensive compressor design expertise

From design to installation, our compressor solution saves you time and effort.

benefit from almost 22 years of experience.

For years, Keepwin has been a leading manufacturer of high-performance compressors, serving a diverse range of industries. With our extensive R&D expertise, we can provide custom-engineered solutions to meet your specific needs. Our global network of distributors offers reliable after-sales support to ensure your operations run smoothly.

Precise calculations and design based on your needs and site conditions

Buy raw materials, forge components, and assemble the compressor

Undergoes a 4-hour factory test run under nitrogen conditions

Deliver the compressor to your site and provide on-site commissioning.

Get the most accurate compressor design in no time.

We will arrange for a professional engineer to design a solution to suit your needs.

*We respect your privacy. Upon submission, our dedicated Keepwin specialists will get in touch at their soonest availability.