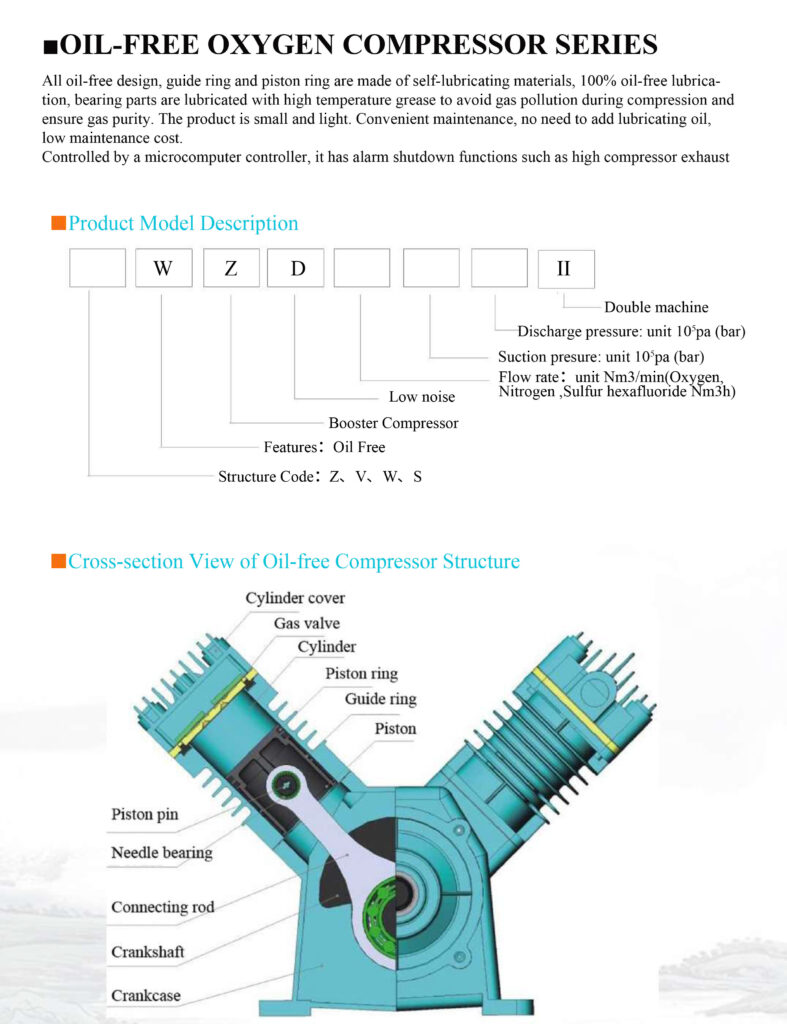

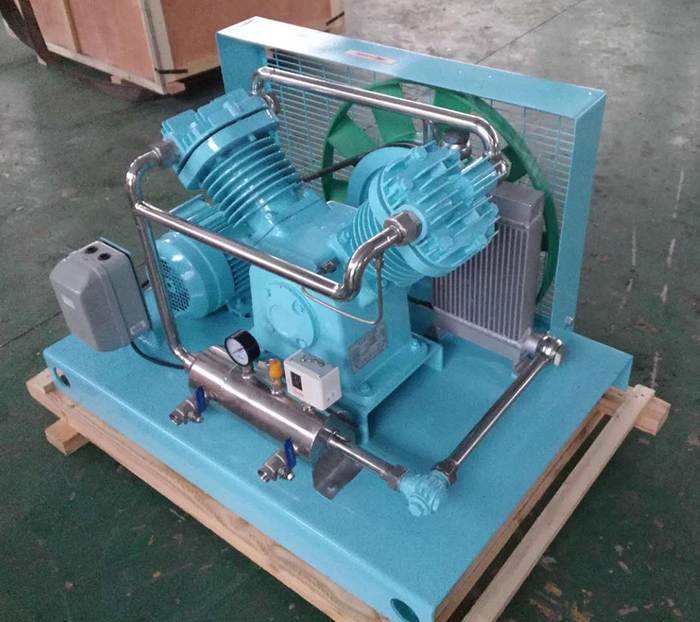

Kompresor Piston Kecil Bebas Oli

Experience the benefits of our oil-free piston compressors: reliable, efficient, and quiet operation. Ideal for applications requiring the highest levels of air purity, our compressors are designed to meet your most demanding needs.