In petrochemical plants, compressor stations are mission-critical yet often time‑intensive to build. Modular skid-mounted compressors offer a transformational solution: pre-assembled, factory-tested units that dramatically reduce on-site work, schedule risks, and installation costs.

1. Off-site Fabrication = Faster Deployment

Built entirely within controlled factory conditions, modular compressor skids arrive on-site 80–90% complete—majority of welding, piping, control panels, and testing is done beforehand. This approach avoids weather delays, minimizes civil works interference, and enables parallel construction, compressing project timelines significantly .

2. Consistent Quality & Lower Risk

Factory-built modules undergo stringent quality assurance, including FAT (Factory Acceptance Testing), ensuring reliable operation before shipping. This avoids on-site construction errors, improves compliance with API/ASME codes, and enhances overall system integrity .

3. Reduced CAPEX & Installation Costs

Modular skids minimize field labor, scaffold, and site support—leading to lower labor and civil costs, plus less downtime of existing operations

4. Enhanced Flexibility & Scalability

As plant needs evolve, additional compressor skids can be readily integrated into existing systems. Skids offer plug‑and‑play scalability, ideal for phased expansion or temporary needs. And if required, they can be relocated or repurposed, prolonging asset life .

5. Safer & More Controlled Assembly Environment

Factory workshops follow strict safety practices—overhead cranes, controlled welding labs, and standardized procedures. This reduces on-site safety incidents, especially in congested petrochemical plants .

Comparing Skid vs. Stick-Built Compression Systems

| Feature | Stick-Built System | Skid-Mounted Compressor |

|---|---|---|

| Installation Time | Months of on-site work | Weeks with plug‑and‑play setup |

| Quality Assurance | Variable & weather-dependent | Factory-tested and certified |

| Civil & Site Work | Extensive infrastructure | Minimal connections and foundations |

| Scalability | Complex expansions | Easily scaled with modular add-ons |

| Safety & Reliability | Higher field risk | Safer workshop construction, fewer incidents |

Applications in Petrochemical Projects

-

Gas Injection Stations

-

Booster Compression for Feedstock Lines

-

Recompression at Vacuum Distillation Units

-

Hydrogen, LPG, CO₂ recycling systems

All benefit from modular compressor skids simplifying commissioning and minimizing plant interruptions.

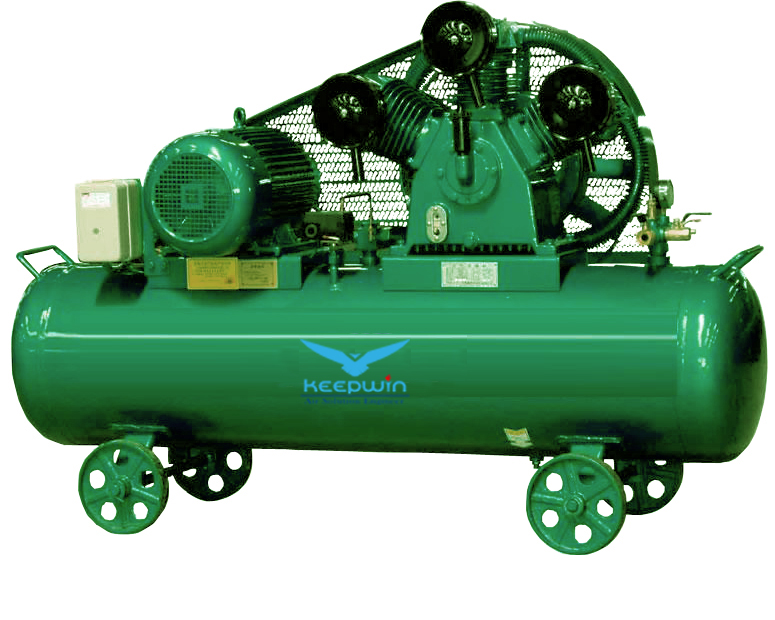

Why KEEPWIN Leads the Way

KEEPWIN engineers fully integrated compressor skids complete with:

-

Screw, reciprocating, or diaphragm compressors

-

Instrumentation & control panel

-

Filters, coolers, valves, pulsation dampers

-

Pre‑wiring and panel PLC/SCADA testing

Our models deliver turnkey, plug‑and‑play systems engineered for quick start-up, high efficiency, and petrochemical-grade safety.

Conclusion

In petrochemical engineering, timing, quality, and flexibility are non-negotiable. Modular skid-mounted compressors deliver on all fronts—reducing CAPEX, accelerating schedules, and enhancing safety. With KEEPWIN’s customized compressor skids, facilities can fast-track delivery, simplify expansions, and ensure compliant, high-performance operations.

👉 Ready to fast-track your compressor installation? Contact KEEPWIN today for a detailed skid compressor solution package!