Gaz associéLe gaz naturel, également appelé gaz de torche ou gaz de tête de puits, est un sous-produit naturel de l'extraction du pétrole brut. Lorsque le pétrole est remonté à la surface, le gaz naturel dissous dans le pétrole est également libéré. Dans de nombreux cas, ce gaz est brûlé à la torche, faute d'infrastructure ou de capacité de traitement.

Cependant, avec une compression et récupération du gazLe gaz associé peut être transformé d'un déchet en un produit de consommation. un combustible ou une matière première de valeurLes objectifs en matière de durabilité énergétique et de conformité à la réglementation.

| Débit | 1250 Nm³/h (conditions standard) |

| Pression d'aspiration | 0,5Mpa(G) |

| Pression de refoulement | 40.0Mpa(G) |

| Temp. de décharge | ≤130°C (sans refroidisseur) |

| Puissance du moteur | 280KW |

| Méthode de refroidissement | Refroidissement par air (pas besoin d'eau) |

| Classe de protection | IP55 / Classe F |

| Structure | Compresseur à piston alternatif de type double V, refroidi par air |

| Taille et poids | 9000*2500*2600mm/ 16600kg |

| Niveau de bruit | ≤85 dB(A) |

Le gaz associé, une fois comprimé et traité, trouve des applications dans diverses industries :

| Domaine d'application | Exemple de cas d'utilisation |

|---|---|

| Pétrole et gaz | Réinjection, gas lift, récupération des gaz de torche |

| Production d'électricité | Moteurs ou turbines à gaz sur site |

| Pétrochimie | Matière première pour la production d'hydrogène ou de gaz de synthèse |

| Systèmes GNC / GNL | Conversion en gaz comprimé/liquéfié |

| Conformité environnementale | Minimisation des torchères et réduction de l'empreinte carbone |

Le gaz associé contient un mélange complexe d'hydrocarbures-comme le méthane, l'éthane, le propane, le butane, le pentane, ainsi que impuretés non hydrocarbures comme le CO₂, l'azote, le H₂S et l'hélium.

Un bâtiment spécialement conçu à cet effet compresseur de gaz associé offre les avantages suivants :

✅ Traitement des flux de gaz multicomposants

✅ Conçu pour pression et débit variables

✅ Assure compression sans fuite et sans huile

✅ Supports température ambiante élevée et champ éloigné fonctionnement

✅ Active récupération d'énergie à partir de gaz de torche

Dans les champs pétrolifères du sud-est TurquieUne entreprise du secteur de l'énergie en amont a été confrontée à un problème récurrent : des volumes importants de déchets. gaz associé étaient brûlés à la torche en raison de l'insuffisance des infrastructures de compression. Cette situation n'a pas seulement causé sanctions environnementales mais aussi de gaspiller de précieuses ressources énergétiques.

L'objectif du client était de récupérer et de comprimer ce gaz de torche, riche en hydrocarbures, pour en faire une source d'énergie renouvelable. production d'électricité sur site et réinjection de gaz.

Pour ce faire, ils avaient besoin d'une solution de compresseur hautement personnalisée, capable de gérer compositions gazeuses complexes à pressions de refoulement extrêmes jusqu'à 40 MPa (400 bar).

Composition du gaz : Complexe et exigeante

Composition du gaz : Complexe et exigeanteLe gaz associé utilisé dans ce projet était un flux d'hydrocarbures multicomposants, consistant principalement en

Méthane (CH₄) : 73.01%

Éthane (C₂H₆) : 9.9%

Propane (C₃H₈) : 9.2%

Butanes, pentanes, hexanes (C₄-C₆) : ~4%

Azote (N₂) : 0,96%

Trace d'oxygène (O₂ < 0,005%)

Ce mélange a présenté des défis uniques en termes de volatilité, gestion de la pressionet sécurité de la lubrification.

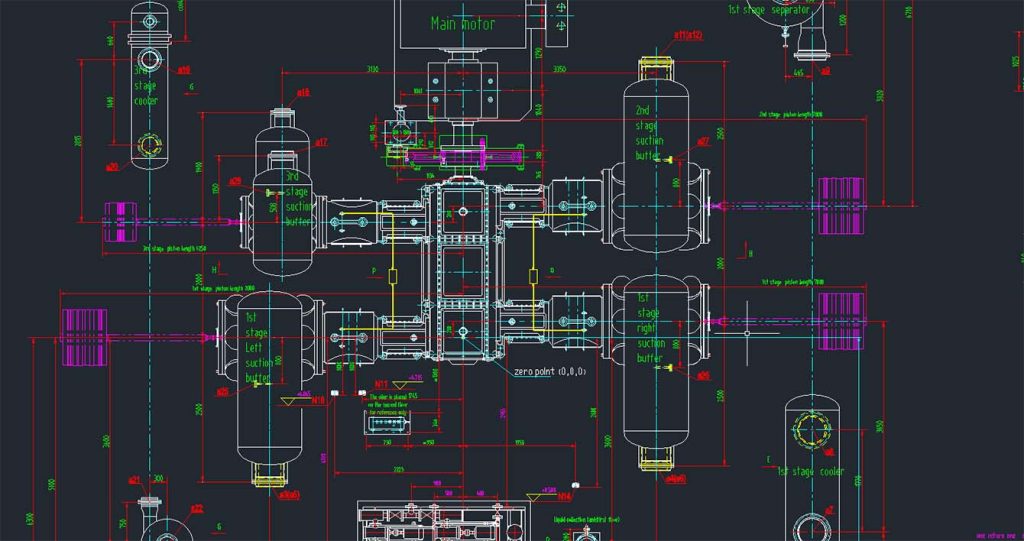

Solution Keepwin : Modèle 2VF-3.6/5-400

Solution Keepwin : Modèle 2VF-3.6/5-400Pour répondre à ces exigences techniques, Keepwin Technology Hebei Co, Ltd. a livré un double V entièrement personnalisé-compresseur alternatif à 5 étages refroidi par air, modèle 2VF-3.6/5-400capable de comprimer le gaz provenant de 0,5 MPa (g) à 40 MPa (g).

Principales spécifications :

Principales spécifications :| Objet | Valeur |

|---|---|

| Capacité Débit | 1250 Nm³/h (3,6 m³/min) |

| Stades de compression | 5 |

| Type de refroidissement | Refroidissement par air (pas besoin d'eau) |

| Lubrification | Injection d'huile d'arbre + d'huile de cylindre |

| Température de refoulement | ≤160°C |

| Puissance du moteur | 280 kW, dIIBT4, antidéflagrant |

| Système d'entraînement | Couplage direct élastique |

| Méthode de démarrage | Démarrage progressif |

| Système de contrôle | PLC + transmetteur + écran tactile |

| Empreinte | 9000×2500×2600 mm |

| Poids | 16 600 kg |

Fourniture d'un service clé en main

Fourniture d'un service clé en mainEn plus du skid du compresseur, Keepwin a fourni :

Armoire de commande antidéflagrante PLC

Refroidisseur + système de refroidissement par ventilateur axial

Réservoir tampon et pipeline de vannes

Injection d'huile + système d'assainissement

Détection des fuites de gaz + alarmes de sécurité

Couverture de la cabine avec éclairage + chauffage environnemental

Kit d'accessoires complet : pièces de rechange, outils, manuels.

Cette conception clé en main a permis au client de intégrer rapidementavec un minimum de modifications sur place.

Résultats et impact

Résultats et impactAprès la mise en service, le système a permis au client de.. :

Les 2VF-3.6/5-400 a fonctionné de manière fiable pendant plus de 6 000 heures avec un entretien standard.

| Fonctionnalité | Avantage Keepwin |

|---|---|

| ✅ Technologie sans huile | Pas de contamination des gaz, pas de séparation de l'huile nécessaire |

| ✅ Modulaire, sur mesure | Construit selon les spécifications en matière de débit, de pression et de composition |

| ✅ Des performances éprouvées sur le terrain | Présente dans plus de 35 pays, y compris au Moyen-Orient et en Asie centrale |

| ✅ Ingénierie des poids lourds | Vilebrequin forgé, revêtement anticorrosion, moteurs de classe B/F |

| ✅ Plus de 40 ans d'expertise technique | R&D, usinage et intégration de systèmes complets en interne |

| ✅ Livraison rapide | Les unités standard sont prêtes dans un délai de 45 à 60 jours ouvrables |

Qu'il s'agisse de développer un système de gas lift, de minimiser les émissions des torchères ou d'alimenter des moteurs sur site, Keepwin fournit solutions de compression de bout en bout pour les flux de gaz associés les plus complexes.

📩 Contactez nous à keepwin@keep-win.com

🌐 Visiter: www.keep-win.com

📞 Consulter nos ingénieurs pour des conseils techniques ou des propositions d'agencement en 3D.

Ce n'est pas pour rien que les fabricants du monde entier se tournent vers Keepwin en tant que premier fabricant de compresseurs. De la fabrication industrielle à l'énergie industrielle et tout ce qui se trouve entre les deux, nos systèmes sont reconnus dans plus de 100 pays et régions depuis plus de 20 ans.

Prêt à faire évoluer votre secteur vers de nouveaux sommets ? Poursuivez votre lecture pour découvrir ce qui fait de Keepwin le choix évident pour les compresseurs de gaz.

Fabriqué selon la norme ISO9001 ISO14001. Certificat CE TUV ASME Etc

Ingénieur très expérimenté avec 39 ans d'expérience dans la conception de compresseurs

De la conception à l'installation, notre solution de compresseur vous permet de gagner du temps et de l'énergie.

bénéficier de près de 22 ans d'expérience.

Depuis des années, Keepwin est l'un des principaux fabricants de compresseurs de haute performance, au service d'un large éventail d'industries. Grâce à notre vaste expertise en R&D, nous pouvons fournir des solutions sur mesure pour répondre à vos besoins spécifiques. Notre réseau mondial de distributeurs offre un service après-vente fiable pour garantir le bon déroulement de vos opérations.

Calculs et conception précis basés sur vos besoins et les conditions du site

Acheter des matières premières, forger des composants et assembler le compresseur.

Test d'usine de 4 heures dans des conditions d'azote

Livraison du compresseur sur votre site et mise en service sur place.

Obtenez en un rien de temps la conception la plus précise possible du compresseur.

Nous ferons en sorte qu'un ingénieur professionnel conçoive une solution adaptée à vos besoins.

*Nous respectons votre vie privée. Une fois votre demande soumise, nos spécialistes Keepwin vous contacteront dès qu'ils seront disponibles.