Compresseur d'hydrogène gazeux

Hydrogen gas is a colorless, odorless, tasteless, flammable gas that is the lightest element on the periodic table. It has a wide range of applications due to its unique properties, including high energy density and clean combustion.

Hydrogen gas compressors are essential equipment used to increase the pressure of hydrogen gas. They find applications in various industries, such as:

- Fuel cell electric vehicles

- Chemical production

- Aerospace

- Electronics

Keepwin Diaphragm Hydrogen Compressor: Powering the Future of Hydrogen Fueling

- Model: GD-500/25-400

- Type: D type Two stages Double action Water cooled Oil-Free

- Capacity: 500Nm3/h

- Suction Pressure: 25bar

- Discharge pressure: 400bar

- Speed: 420r/min

- Water consumption: 10t/h

- Motor power: 110Kw

- Motor: Y Series Asynchronism High efficient DIICT4 Explosion-proof

- Dimension: 4300*3000*2000

- Weight: 14700kg

Application of Hydrogen Compressors in Hydrogen Refueling Stations

Hydrogen compressors are essential components of hydrogen refueling stations. Their primary function is to compress low-pressure hydrogen gas to high pressure to meet the fueling demands of hydrogen fuel cell vehicles.

Working Principle Hydrogen compressors convert mechanical energy into the compression of hydrogen gas. When hydrogen enters the compression chamber, a piston or rotor compresses the gas, reducing its volume and increasing its pressure. Through multiple stages of compression, the hydrogen reaches the required pressure for refueling stations, typically 20-90 MPa.

What’s the Hydrogen Refueling Stations ?

- Stockage de l'hydrogène : High-pressure hydrogen is stored in storage tanks to meet the continuous fueling needs of vehicles.

- Hydrogen Fueling: High-pressure hydrogen is dispensed into a vehicle’s hydrogen fuel cell system through a fueling dispenser.

- Ensuring Hydrogen Purity: Hydrogen compressors are often equipped with efficient filtration systems to ensure the purity of the hydrogen dispensed into vehicles.

How Dose the Hydrogen Compressor Working in a Hydrogen Refueling Station?

- Low-pressure Hydrogen Inlet: Low-pressure hydrogen enters the compressor from the hydrogen supply source.

- Multi-stage Compression: The hydrogen undergoes multiple stages of compression within the compressor, gradually increasing its pressure.

- Cooling: The heat generated during compression is dissipated through a cooling system.

- Stockage de l'hydrogène : The high-pressure hydrogen is transported to the storage tank for storage.

- Hydrogen Fueling: Vehicles enter the refueling station and receive high-pressure hydrogen from the fueling dispenser into their hydrogen fuel cell system.

Three Importances of Hydrogen Compressors in Hydrogen Refueling Stations

- Ensuring Operating Efficiency: High-efficiency hydrogen compressors improve the operating efficiency of refueling stations and reduce fueling time.

- Ensuring Hydrogen Quality: High-purity hydrogen extends the lifespan of fuel cells and improves vehicle performance.

- Safety Assurance: Hydrogen compressors must have comprehensive safety protection measures to ensure the safe operation of refueling stations.

Five Benefits for Hydrogen Refueling Station Operators

By choosing a Keepwin diaphragm hydrogen compressor, refueling station operators can benefit from:

- Reduced operating costs: High efficiency and minimal maintenance requirements contribute to lower operating costs.

- Improved reliability: The robust design and advanced materials ensure long-term reliability.4000 hours non stop operation.

- Enhanced safety: The diaphragm design and safety features minimize the risk of accidents.

- Compliance with industry standards: Keepwin compressors meet or exceed all relevant industry standards and regulations.

- Environmental sustainability: 100% oil free, 0 Pollution to the gas medium.

Pourquoi nous choisir ?

découvrez la différence keepwin

Ce n'est pas pour rien que les fabricants du monde entier se tournent vers Keepwin en tant que premier fabricant de compresseurs. De la fabrication industrielle à l'énergie industrielle et tout ce qui se trouve entre les deux, nos systèmes sont reconnus dans plus de 100 pays et régions depuis plus de 20 ans.

Prêt à faire évoluer votre secteur vers de nouveaux sommets ? Poursuivez votre lecture pour découvrir ce qui fait de Keepwin le choix évident pour les compresseurs de gaz.

Contrôle strict de la qualité

Fabriqué selon la norme ISO9001 ISO14001. Certificat CE TUV ASMI Etc

Ingénieurs chevronnés

Ingénieur très expérimenté avec 39 ans d'expérience dans la conception de compresseurs

Consultation et personnalisation

De la conception à l'installation, notre solution de compresseur vous permet de gagner du temps et de l'énergie.

Meilleure usine et prix de l'énergie

bénéficier de près de 22 ans d'expérience.

Comment nous travaillons

Nos solutions vous permettent de travailler facilement sur votre projet

Depuis des années, Keepwin est l'un des principaux fabricants de compresseurs de haute performance, au service d'un large éventail d'industries. Grâce à notre vaste expertise en R&D, nous pouvons fournir des solutions sur mesure pour répondre à vos besoins spécifiques. Notre réseau mondial de distributeurs offre un service après-vente fiable pour garantir le bon déroulement de vos opérations.

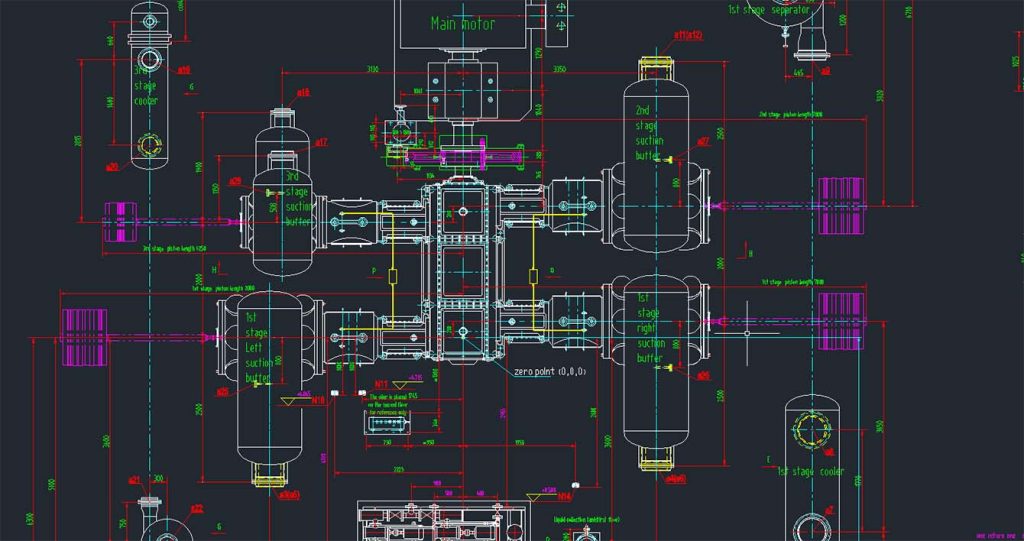

Design & Caculate

Calculs et conception précis basés sur vos besoins et les conditions du site

Usinage et assemblage

Acheter des matières premières, forger des composants et assembler le compresseur.

Essai et peinture

Test d'usine de 4 heures dans des conditions d'azote

expédition et commission

Livraison du compresseur sur votre site et mise en service sur place.