Compresor de hidrógeno gaseoso

Hydrogen gas is a colorless, odorless, tasteless, flammable gas that is the lightest element on the periodic table. It has a wide range of applications due to its unique properties, including high energy density and clean combustion.

Hydrogen gas compressors are essential equipment used to increase the pressure of hydrogen gas. They find applications in various industries, such as:

- Fuel cell electric vehicles

- Chemical production

- Aerospace

- Electronics

Keepwin Diaphragm Hydrogen Compressor: Powering the Future of Hydrogen Fueling

- Model: GD-500/25-400

- Type: D type Two stages Double action Water cooled Oil-Free

- Capacity: 500Nm3/h

- Suction Pressure: 25bar

- Discharge pressure: 400bar

- Speed: 420r/min

- Water consumption: 10t/h

- Motor power: 110Kw

- Motor: Y Series Asynchronism High efficient DIICT4 Explosion-proof

- Dimension: 4300*3000*2000

- Weight: 14700kg

Application of Hydrogen Compressors in Hydrogen Refueling Stations

Hydrogen compressors are essential components of hydrogen refueling stations. Their primary function is to compress low-pressure hydrogen gas to high pressure to meet the fueling demands of hydrogen fuel cell vehicles.

Working Principle Hydrogen compressors convert mechanical energy into the compression of hydrogen gas. When hydrogen enters the compression chamber, a piston or rotor compresses the gas, reducing its volume and increasing its pressure. Through multiple stages of compression, the hydrogen reaches the required pressure for refueling stations, typically 20-90 MPa.

What’s the Hydrogen Refueling Stations ?

- Almacenamiento de hidrógeno: High-pressure hydrogen is stored in storage tanks to meet the continuous fueling needs of vehicles.

- Hydrogen Fueling: High-pressure hydrogen is dispensed into a vehicle’s hydrogen fuel cell system through a fueling dispenser.

- Ensuring Hydrogen Purity: Hydrogen compressors are often equipped with efficient filtration systems to ensure the purity of the hydrogen dispensed into vehicles.

How Dose the Hydrogen Compressor Working in a Hydrogen Refueling Station?

- Low-pressure Hydrogen Inlet: Low-pressure hydrogen enters the compressor from the hydrogen supply source.

- Multi-stage Compression: The hydrogen undergoes multiple stages of compression within the compressor, gradually increasing its pressure.

- Cooling: The heat generated during compression is dissipated through a cooling system.

- Almacenamiento de hidrógeno: The high-pressure hydrogen is transported to the storage tank for storage.

- Hydrogen Fueling: Vehicles enter the refueling station and receive high-pressure hydrogen from the fueling dispenser into their hydrogen fuel cell system.

Three Importances of Hydrogen Compressors in Hydrogen Refueling Stations

- Ensuring Operating Efficiency: High-efficiency hydrogen compressors improve the operating efficiency of refueling stations and reduce fueling time.

- Ensuring Hydrogen Quality: High-purity hydrogen extends the lifespan of fuel cells and improves vehicle performance.

- Safety Assurance: Hydrogen compressors must have comprehensive safety protection measures to ensure the safe operation of refueling stations.

Five Benefits for Hydrogen Refueling Station Operators

By choosing a Keepwin diaphragm hydrogen compressor, refueling station operators can benefit from:

- Reduced operating costs: High efficiency and minimal maintenance requirements contribute to lower operating costs.

- Improved reliability: The robust design and advanced materials ensure long-term reliability.4000 hours non stop operation.

- Enhanced safety: The diaphragm design and safety features minimize the risk of accidents.

- Compliance with industry standards: Keepwin compressors meet or exceed all relevant industry standards and regulations.

- Environmental sustainability: 100% oil free, 0 Pollution to the gas medium.

Por qué elegirnos

descubra la diferencia keepwin

Hay una razón por la que los fabricantes de todo el mundo recurren a Keepwin como el mejor fabricante de compresores. Desde la fabricación industrial a la industria energética y todo lo que hay entre medias, nuestros sistemas gozan de la confianza de más de 100 países y regiones desde hace más de 20 años.

¿Listo para llevar su industria a nuevas cotas? Siga leyendo para saber qué hace de Keepwin la elección clara en compresores de gas

Estricto control de calidad

Fabricado según la norma ISO9001 ISO14001. Certificado CE TUV ASMI Etc

Ingenieros experimentados

Ingeniero altamente experimentado con 39 años de amplia experiencia en el diseño de compresores

Consulta y personalización

Desde el diseño hasta la instalación, nuestra solución de compresores le ahorra tiempo y esfuerzo.

Mejor fábrica de energía y premio

beneficiarse de casi 22 años de experiencia.

Cómo trabajamos

Nuestras soluciones le facilitan el trabajo en su proyecto

Durante años, Keepwin ha sido un fabricante líder de compresores de alto rendimiento, al servicio de una amplia gama de industrias. Gracias a nuestra amplia experiencia en I+D, podemos ofrecer soluciones a medida para satisfacer sus necesidades específicas. Nuestra red mundial de distribuidores ofrece un servicio posventa fiable para garantizar que sus operaciones se desarrollen sin problemas.

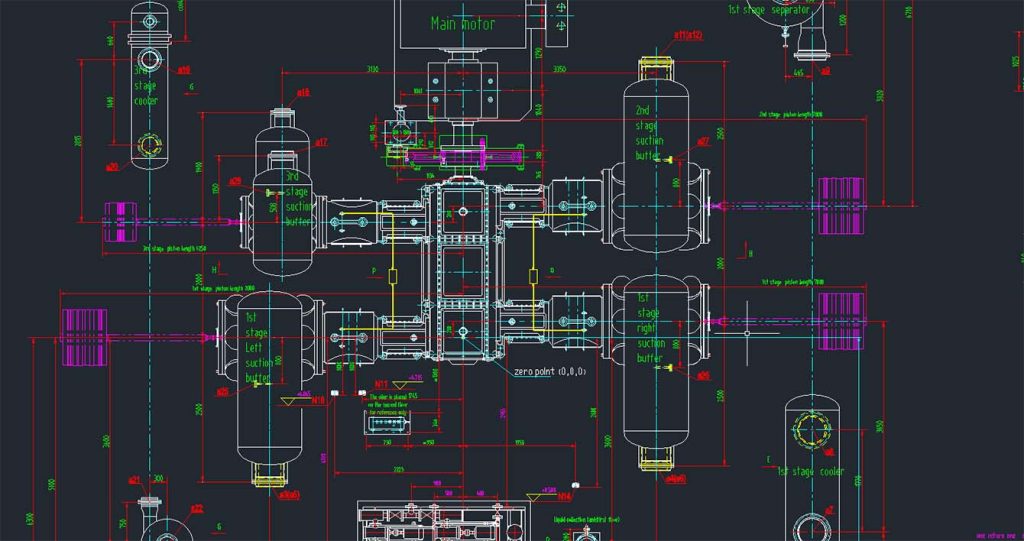

Diseño y Caculado

Cálculos y diseño precisos basados en sus necesidades y en las condiciones del emplazamiento

Mecanizado y montaje

Comprar materias primas, forjar componentes y montar el compresor

prueba de funcionamiento y pintura

Se somete a una prueba de fábrica de 4 horas en condiciones de nitrógeno

envíos y comisiones

Entregamos el compresor en sus instalaciones y realizamos la puesta en marcha in situ.