Los compresores industriales son equipos esenciales en sectores como la energía, la química, la metalurgia, la electrónica y el suministro de gases médicos. La elección del tipo de compresor correcto afecta directamente a la eficiencia del sistema, la estabilidad operativa y la seguridad. Este documento describe las principales categorías de compresores y ofrece una guía estructurada para ayudar a los profesionales a seleccionar el más adecuado para sus aplicaciones. 🔧 [...]

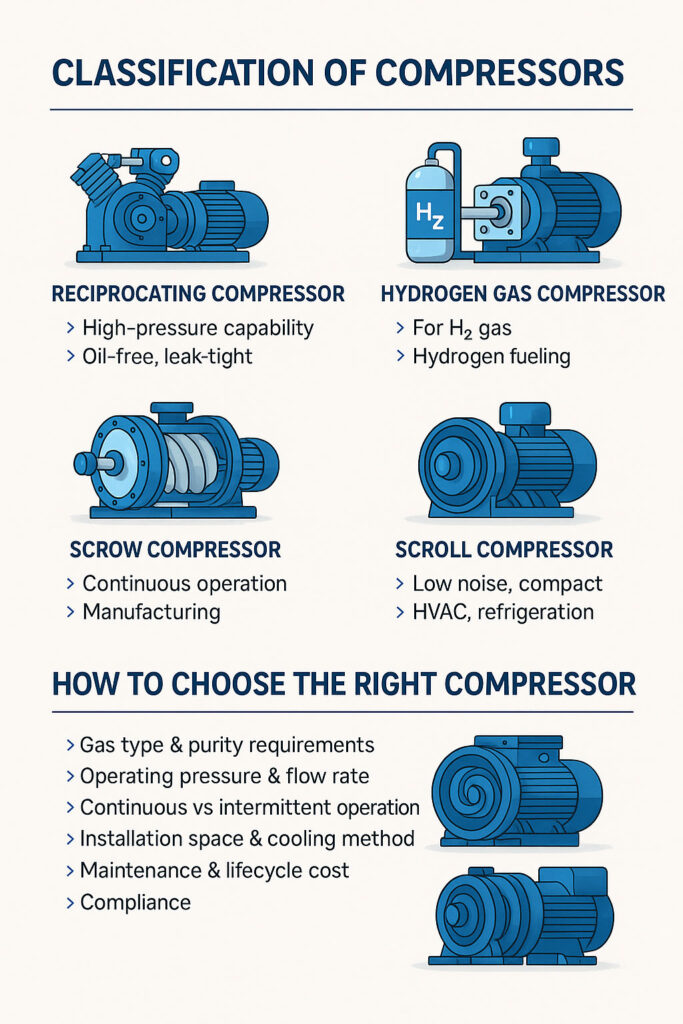

🔧 1. Compresores alternativos

🔧 1. Compresores alternativos

Visión general:

Los compresores alternativos utilizan pistones accionados por un cigüeñal para suministrar gas a alta presión.

Ventajas:

Capacidad de alta presión

Adecuado para caudales pequeños y medianos

Mantenimiento modular

Lo mejor para:

Plantas petroquímicas, refuerzo del gas natural, estaciones de GNC

💡 2. Compresores de membrana

Visión general:

Se trata de compresores exentos de aceite que utilizan una membrana para aislar el gas de las piezas mecánicas.

Ventajas:

Suministro de gas totalmente exento de aceite

Ideal para gases de alta pureza y peligrosos

Diseño estanco

Lo mejor para:

Compresión de hidrógeno, oxígeno, helio y gases medicinales

⚙️ 3. Compresores de tornillo (compresores rotativos)

Visión general:

Los compresores de tornillo rotativo son máquinas de servicio continuo que comprimen gas mediante dos rotores helicoidales.

Ventajas:

Funcionamiento continuo

Menor vibración

Alta eficiencia para presiones medias

Lo mejor para:

Fabricación, electrónica, metalurgia, herramientas neumáticas

🌀 4. Compresores Scroll

Visión general:

Los compresores scroll utilizan espirales en órbita para comprimir el gas.

Ventajas:

Funcionamiento silencioso

Eficiencia energética

Tamaño compacto

Lo mejor para:

HVAC, refrigeración, laboratorios

💨 5. Compresores centrífugos

Visión general:

Estos compresores dinámicos utilizan impulsores para imprimir velocidad al gas y convertirla en presión.

Ventajas:

Gran capacidad de caudal

Menos piezas móviles

Adecuado para operaciones a gran escala

Lo mejor para:

Plantas de separación de aire, GNL, procesos químicos

🔬 6. Compresores de hidrógeno gaseoso

Visión general:

Unidades especializadas diseñadas para manipular gas hidrógeno ligero y explosivo a alta presión.

Ventajas:

Preferiblemente de diafragma o pistón sin aceite

Altas relaciones de compresión

Excelente estanqueidad y seguridad

Lo mejor para:

Estaciones de abastecimiento de hidrógeno, almacenamiento de energías renovables, producción de amoníaco

⚖️ 7. Scroll vs Tornillo vs Reciprocante: Comparación rápida

| Tipo | Rango de presión | Capacidad de caudal | Mantenimiento | Caso típico |

|---|---|---|---|---|

| Reciprocante | Alta | Bajo-Medio | Moderado | Gasoducto, GNC |

| Diafragma | Alta | Bajo | Bajo | Gases especiales, laboratorios |

| Tornillo | Medio | Medio-Alto | Bajo | Automatización industrial |

| Desplácese por | Bajo-Medio | Bajo | Bajo | HVAC, refrigeración |

| Centrífuga | Bajo-Medio | Alta | Bajo | GNL, procesos a gran escala |

| Compresores de hidrógeno | Muy alta | Bajo-Medio | Medio-Alto | Energía de hidrógeno, tecnología limpia |

🧭 Cómo elegir el compresor adecuado

Al seleccionar un compresor, tenga en cuenta los siguientes factores:

Tipo de gas y requisitos de pureza (por ejemplo, tóxicos, explosivos, de gran pureza)

Presión de funcionamiento y caudal

Funcionamiento continuo o intermitente

Espacio de instalación y método de refrigeración

Mantenimiento y coste del ciclo de vida

Conformidad (certificaciones CE, ATEX, ISO)

🔧 1. Compresores alternativos

🔧 1. Compresores alternativos