Por qué los compresores de GLP deben evolucionar ya

El imperativo del hidrógeno: Por qué los compresores de GLP deben evolucionar ahora Para 2030, las normas de emisiones de la UE obligarán a mezclar hidrógeno en los sistemas de GLP en concentraciones volumétricas mínimas de 10%, que aumentarán hasta 25% en 2040 57. Este cambio pretende reducir las emisiones de metano (GWP 84x CO₂) y acelerar la neutralidad de carbono. Los compresores tradicionales fallan aquí: la permeación del hidrógeno provoca la fragilización de las válvulas, la degradación de las juntas [...]

Cómo la IA reduce el tiempo de inactividad de los compresores de GLP en 50%

Las paradas imprevistas cuestan a las plantas de GLP $58.000/hora, pero 74% de las averías muestran señales de advertencia con días de antelación. El mantenimiento tradicional pasa por alto estas señales. Descubra cómo los sistemas predictivos basados en IA transforman las reparaciones reactivas en previsiones de precisión. El trío tecnológico que revoluciona el mantenimiento El sistema AI Guardian de KEEPWIN combina: Huella digital de vibraciones Detecta la desalineación de la barra a partir de desviaciones de 0,01 mm (certificado ISO 10816-6) Gemelos digitales térmicos [...]

Instalaciones de compresores de GLP de 48 horas: La revolución africana de la cocina limpia

Cómo los compresores montados sobre patines resuelven la crisis energética de África en 48 horas África gasta 1.5T22.000 millones al año en combustibles peligrosos para cocinar, mientras que 70% de las importaciones de GLP se quedan varadas en los puertos por falta de infraestructura de compresión. La tecnología de compresores modulares colma esta laguna, convirtiendo los contenedores de transporte marítimo en centros de distribución de gas en dos días. El núcleo de la innovación: Unidades móviles Plug-and-Play KEEPWIN [...]

Cómo los compresores de GLP para yacimientos petrolíferos reducen el OPEX en 30%

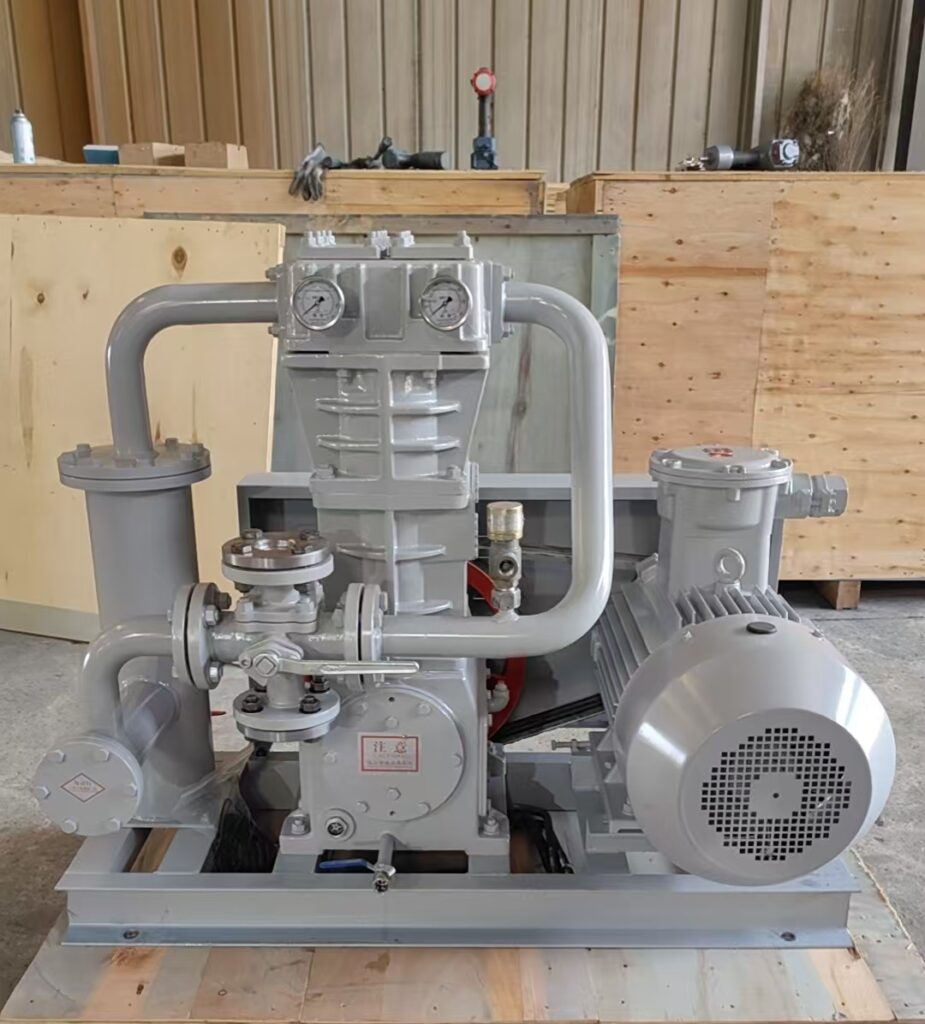

Compresores hidráulicos de pistón: La solución $1,2M/año para la quema de gas en yacimientos petrolíferos Los yacimientos petrolíferos mundiales desperdician $16.000 millones al año en la quema de gas asociado rico en GLP. Los compresores de tornillo tradicionales fallan cuando el contenido de azufre supera los 5%, obligando a los operadores a quemar valioso combustible. Descubra cómo la tecnología de pistones hidráulicos transforma los residuos en beneficios. Por qué los sistemas hidráulicos rinden mejor en gas ácido La serie DY-V de KEEPWIN combate los retos de los yacimientos petrolíferos con: Sellado [...]

¿Cómo reducen los compresores de recuperación de BOG las pérdidas de las terminales de GNL en 40%?

Cada año, las terminales de GNL pierden $2,2 millones por la evaporación del gas de ebullición (BOG) durante el almacenamiento y la transferencia. Los compresores de pistón tradicionales agravan esta situación debido a los frecuentes ciclos de arranque y parada y a la contaminación del lubricante. A continuación se explica cómo la tecnología de recuperación de BOG de última generación aborda estos problemas, con datos concretos de terminales operativas. El núcleo de la innovación: Cojinetes magnéticos + control VFD La solución de KEEPWIN integra dos [...]