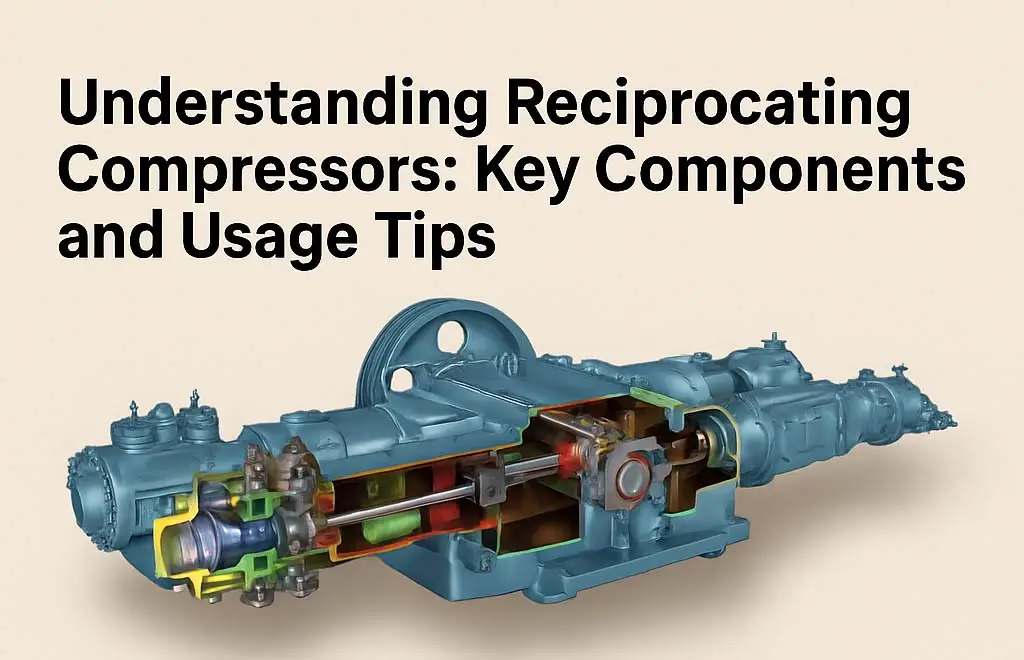

3 Mistakes to Avoid When Using a Reciprocating Compressor

A reciprocating compressor is one of the most trusted solutions for compressing air and gas in a wide range of industries. However, even the most robust compressors can underperform or fail prematurely if used improperly. To help you extend the life of your equipment and increase compressor efficiency, we’ve listed 3 critical mistakes you should […]

The Difference Between SCFM and CFM Explained

When researching air compressors, you’ve likely come across both SCFM and CFM. While they may sound similar, the difference between SCFM and CFM can significantly impact how your compressor performs, especially in industrial settings. In this guide, we’ll break down both terms and explain how they affect compressor efficiency, air compressor capacity, and real-world equipment […]

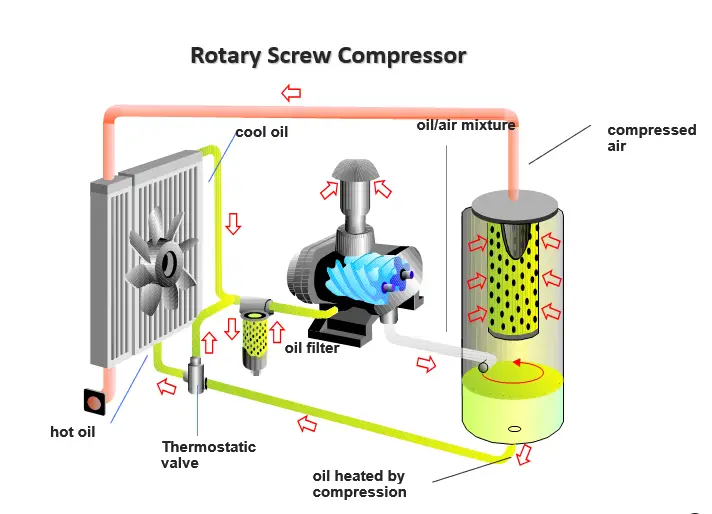

7 Ways to Maximize Efficiency in Your Screw Compressors

In today’s competitive industrial landscape, energy efficiency is no longer optional—it’s essential. If your operation relies on a screw compressor, upgrading its efficiency can translate into significant energy savings, lower maintenance costs, and improved system performance. At Keepwin Technology Hebei Co., Ltd., we don’t just build compressors—we engineer smart performance. Here’s how to take your […]

5 Tips for Choosing the Right Diaphragm Compressor

A diaphragm compressor is an essential tool for applications requiring ultra-clean, high-pressure gas delivery. Whether you’re compressing hydrogen, helium, oxygen, or other specialty gases, choosing the right model directly affects performance, safety, and long-term reliability. At Keepwin Technology Hebei Co., Ltd., we’ve supplied custom-engineered diaphragm compressors for over 20 years. Based on that experience, here […]

What Is SCFM and Why It Matters in Air Compressors

If you’re comparing air compressors for industrial or personal use, you’ve likely encountered the term SCFM. But what is SCFM, and why does it matter when selecting a scfm air compressor? In this article, we’ll explore the definition of SCFM, how it differs from CFM, and why understanding this value is crucial to ensuring peak […]

Enhancing Offshore Operations with High-Pressure Oil-Free Nitrogen Compressors and Membrane Nitrogen Generators

In demanding offshore and industrial environments, the need for reliable and efficient nitrogen supply systems is paramount. Integrating high-pressure, oil-free nitrogen compressors with membrane nitrogen generators offers a solution that meets stringent purity requirements while enhancing operational efficiency. High-Pressure Compressors High-pressure compressors are engineered to deliver nitrogen at pressures up to 700 bar, essential for […]

High-Pressure Oil-Free Nitrogen Compressors: Enhancing Offshore Gas Lift Applications

On May 17–18, Keepwin Technology Hebei Co., Ltd. had the pleasure of hosting a delegation from Brazil to discuss a customized 700 bar, 500 SCFM nitrogen booster compressor solution. The client operates a membrane nitrogen generation system delivering 20 bar output pressure and seeks to elevate this to 700 bar for offshore gas lift applications […]

Oil-Free Air Compressors: Enhancing Efficiency with Advanced Cooling Systems

In today’s industrial landscape, the demand for clean, efficient, and reliable compressed air is paramount. Oil-free air compressors have emerged as a solution, offering contamination-free air suitable for various applications, from pharmaceuticals to food processing. Understanding Oil-Free Air Compressors Unlike traditional compressors that use oil for lubrication and sealing, oil-free compressors operate without any oil […]

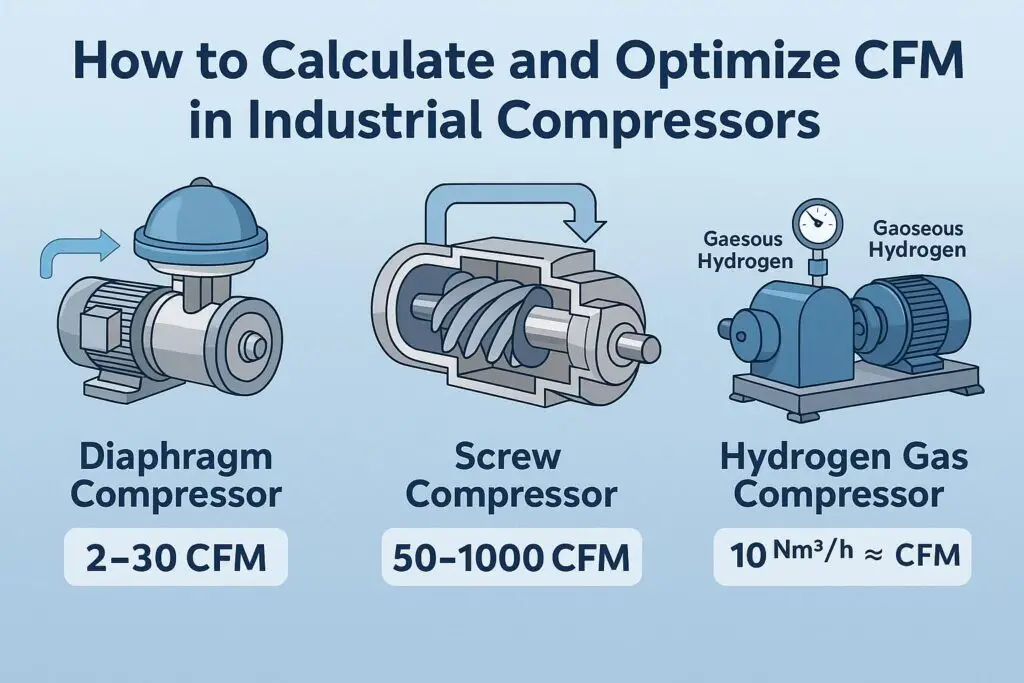

How to Calculate and Optimize CFM in Industrial Compressors: A Guide for Engineers

Choosing an industrial air compressor goes far beyond horsepower and pressure. One of the most critical and often misunderstood metrics is CFM—cubic feet per minute. Whether you’re using a diaphragm compressor, a screw compressor, or a specialized hydrogen gas compressor, knowing how to calculate and optimize your system’s CFM can determine your project’s success. In […]

Comparing Diaphragm, Reciprocating, Screw, and Hydrogen Gas Compressor: Understanding the Differences

Introduction Compressors are integral to numerous industries, facilitating processes that require gas compression. Keepwin Technology Hebei Co., Ltd. specializes in providing a range of compressors, including diaphragm compressors, reciprocating compressors, screw compressors, and hydrogen gas compressors. Understanding the distinctions among these types can aid in selecting the appropriate equipment for specific applications. Diaphragm Compressors Diaphragm […]