Hydrogen Gas Compressor

Hydrogen gas is a colorless, odorless, tasteless, flammable gas that is the lightest element on the periodic table. It has a wide range of applications due to its unique properties, including high energy density and clean combustion.

Hydrogen gas compressors are essential equipment used to increase the pressure of hydrogen gas. They find applications in various industries, such as:

- Fuel cell electric vehicles

- Chemical production

- Aerospace

- Electronics

Keepwin Diaphragm Hydrogen Compressor: Powering the Future of Hydrogen Fueling

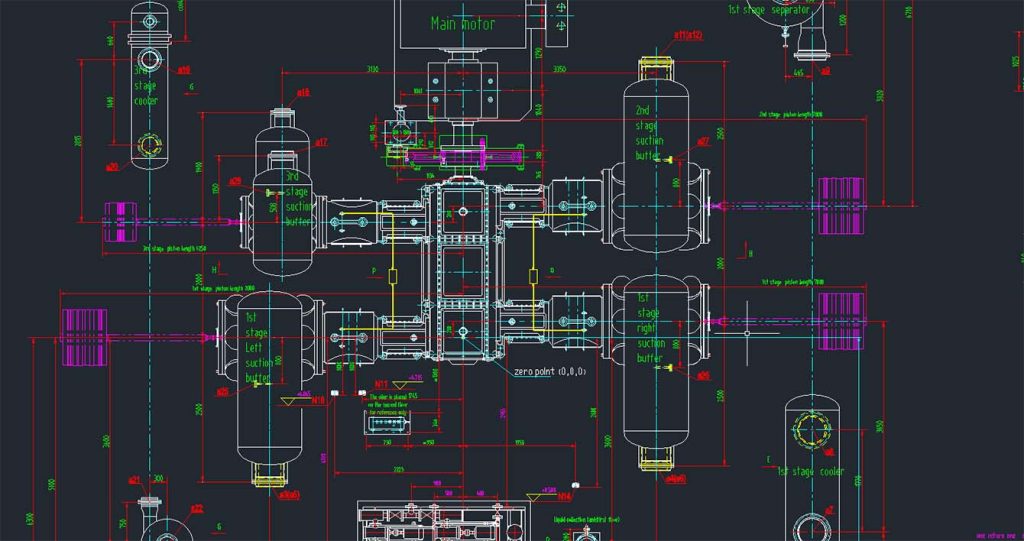

- Model: GD-500/25-400

- Type: D type Two stages Double action Water cooled Oil-Free

- Capacity: 500Nm3/h

- Suction Pressure: 25bar

- Discharge pressure: 400bar

- Speed: 420r/min

- Water consumption: 10t/h

- Motor power: 110Kw

- Motor: Y Series Asynchronism High efficient DIICT4 Explosion-proof

- Dimension: 4300*3000*2000

- Weight: 14700kg

Application of Hydrogen Compressors in Hydrogen Refueling Stations

Hydrogen compressors are essential components of hydrogen refueling stations. Their primary function is to compress low-pressure hydrogen gas to high pressure to meet the fueling demands of hydrogen fuel cell vehicles.

Working Principle Hydrogen compressors convert mechanical energy into the compression of hydrogen gas. When hydrogen enters the compression chamber, a piston or rotor compresses the gas, reducing its volume and increasing its pressure. Through multiple stages of compression, the hydrogen reaches the required pressure for refueling stations, typically 20-90 MPa.

What’s the Hydrogen Refueling Stations ?

- Hydrogen Storage: High-pressure hydrogen is stored in storage tanks to meet the continuous fueling needs of vehicles.

- Hydrogen Fueling: High-pressure hydrogen is dispensed into a vehicle’s hydrogen fuel cell system through a fueling dispenser.

- Ensuring Hydrogen Purity: Hydrogen compressors are often equipped with efficient filtration systems to ensure the purity of the hydrogen dispensed into vehicles.

How Dose the Hydrogen Compressor Working in a Hydrogen Refueling Station?

- Low-pressure Hydrogen Inlet: Low-pressure hydrogen enters the compressor from the hydrogen supply source.

- Multi-stage Compression: The hydrogen undergoes multiple stages of compression within the compressor, gradually increasing its pressure.

- Cooling: The heat generated during compression is dissipated through a cooling system.

- Hydrogen Storage: The high-pressure hydrogen is transported to the storage tank for storage.

- Hydrogen Fueling: Vehicles enter the refueling station and receive high-pressure hydrogen from the fueling dispenser into their hydrogen fuel cell system.

Three Importances of Hydrogen Compressors in Hydrogen Refueling Stations

- Ensuring Operating Efficiency: High-efficiency hydrogen compressors improve the operating efficiency of refueling stations and reduce fueling time.

- Ensuring Hydrogen Quality: High-purity hydrogen extends the lifespan of fuel cells and improves vehicle performance.

- Safety Assurance: Hydrogen compressors must have comprehensive safety protection measures to ensure the safe operation of refueling stations.

Five Benefits for Hydrogen Refueling Station Operators

By choosing a Keepwin diaphragm hydrogen compressor, refueling station operators can benefit from:

- Reduced operating costs: High efficiency and minimal maintenance requirements contribute to lower operating costs.

- Improved reliability: The robust design and advanced materials ensure long-term reliability.4000 hours non stop operation.

- Enhanced safety: The diaphragm design and safety features minimize the risk of accidents.

- Compliance with industry standards: Keepwin compressors meet or exceed all relevant industry standards and regulations.

- Environmental sustainability: 100% oil free, 0 Pollution to the gas medium.

Latest News

- LPG Compressor Applications & Working Principle: 2025 Market Guide

- CTA Three-Stage Filter Cartridge Replacement Guide: Maximize Compressed Air Purity & Save Cost

- Ductile Iron for Compressors & Pumps: ASTM A395 vs QT450-10 Explained

- What to Consider When Selecting a Reciprocating Gas Compressor

- How Nitrogen Boosters Enhance Additive Manufacturing Productivity

Why choose us

discover keepwin difference

There’s a reason why manufacturers worldwide turn to Keepwin as the top compressor manufacturer. From industrial manufacturing to energy industrial and everything in between, our systems have been trusted in 100+ countries and regions for 20+ years.

Ready to take your industry to new heights? Continue reading to learn what makes Keepwin the clear choice for gas compressors

Strict Quality Control

Manufactured as ISO9001 ISO14001 standard. Got CE TUV ASME Etc Certificate

Seasoned Engineers

Highly experienced engineer with 39 years of extensive compressor design expertise

Consultation & customize

From design to installation, our compressor solution saves you time and effort.

Best Energy factory and award

benefit from almost 22 years of experience.

How we work

Our solutions make it easy for you to work on your project

For years, Keepwin has been a leading manufacturer of high-performance compressors, serving a diverse range of industries. With our extensive R&D expertise, we can provide custom-engineered solutions to meet your specific needs. Our global network of distributors offers reliable after-sales support to ensure your operations run smoothly.

Design & Caculate

Precise calculations and design based on your needs and site conditions

Machining & assembly

Buy raw materials, forge components, and assemble the compressor

test run & Painting

Undergoes a 4-hour factory test run under nitrogen conditions

shipping & commission

Deliver the compressor to your site and provide on-site commissioning.