Your Ultimate Guide to Oil-Free, High-Purity Gas Compression

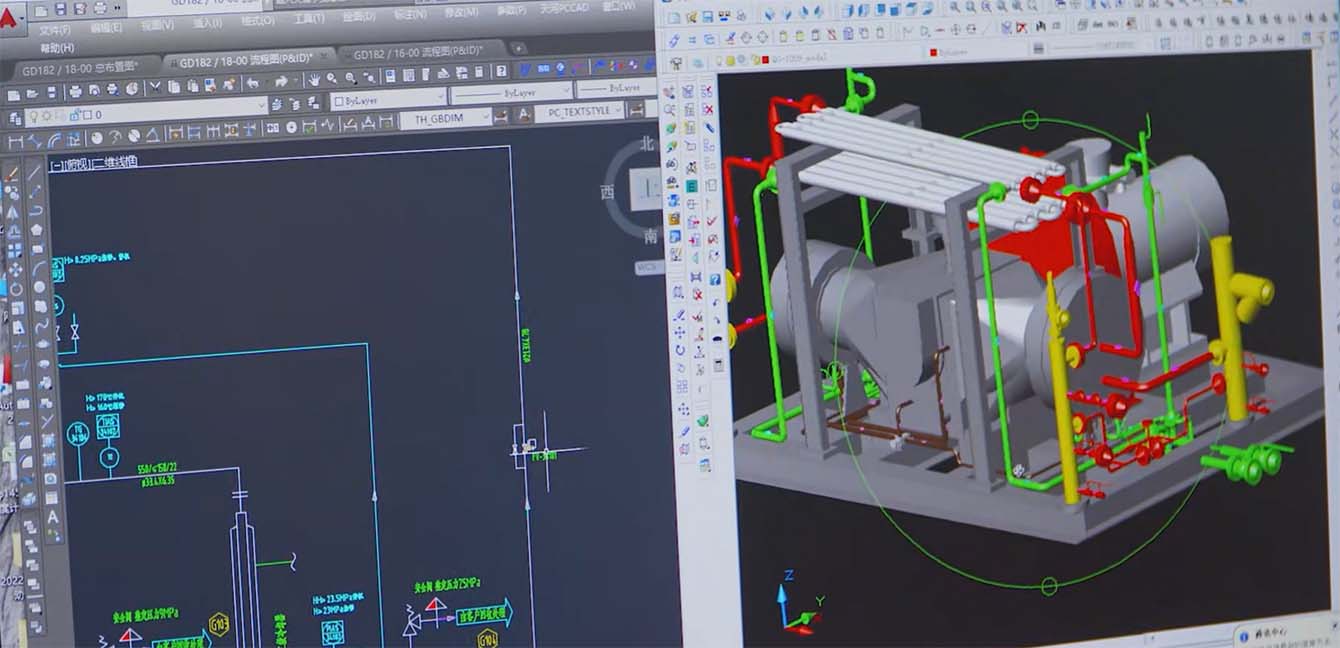

As industries demand cleaner and safer gas handling solutions, diaphragm compressors have emerged as a critical technology for high-pressure industrial gas compression. At Keepwin Technology Hebei Co., Ltd., we specialize in engineering precision diaphragm compressors tailored for sectors where purity, reliability, and zero contamination are non-negotiable.

How Does a Diaphragm Compressor Work?

A diaphragm compressor uses a flexible metal diaphragm to isolate gas from lubricants and contaminants, making it ideal for oil-free gas compression. Here’s the science:

Compression Cycle: The diaphragm flexes via a hydraulic or mechanical actuator, compressing gas within a sealed chamber.

Zero Contamination: No piston rings or lubricants contact the gas, ensuring 100% purity – crucial for industries like pharmaceuticals, semiconductors, and hydrogen energy.

High-Pressure Output: Capable of reaching 250–3,000 bar, these compressors handle demanding applications like gas cylinder filling and chemical processing.

Key Applications of Industrial Diaphragm Compressors

From labs to heavy industries, diaphragm compressors power mission-critical operations:

Hydrogen Fuel Stations: Safe compression of high-purity hydrogen gas.

Medical Gas Systems: Oxygen, nitrogen, and anesthetic gas delivery.

Chemical Processing: Handling corrosive or explosive gases like chlorine and ethylene.

Semiconductor Manufacturing: Ultra-clean argon, helium, and nitrogen compression.

Why Choose Keepwin’s Diaphragm Compressors?

As a leading industrial gas compressor manufacturer, Keepwin Technology delivers unmatched advantages:

✅ Oil-Free & Hermetic Design

Eliminate contamination risks with ISO 8573-1 Class 0-certified compression – perfect for sensitive gases.

✅ Customized Pressure Ranges

From 50 bar to 3,000 bar, our compressors adapt to your exact industrial gas compression needs.

✅ Low Maintenance & High Durability

Advanced metal diaphragms (stainless steel or titanium) ensure 20,000+ hours of service life with minimal downtime.

✅ Global Compliance

CE, ASME, and PED certifications guarantee safety and performance across international markets.

Diaphragm Compressor vs. Traditional Compressors

While reciprocating or screw compressors dominate general industries, diaphragm compressors excel where purity and precision matter:

| Feature | Diaphragm Compressor | Reciprocating Compressor |

|---|---|---|

| Contamination Risk | Zero (oil-free) | High (lubricant contact) |

| Max Pressure | Up to 3,000 bar | Typically < 500 bar |

| Ideal For | High-value gases, labs, R&D | General manufacturing |

Upgrade to Keepwin’s Next-Gen Diaphragm Compressors

Whether you’re compressing hydrogen, medical oxygen, or specialty gases, our industrial diaphragm compressors combine cutting-edge engineering with rigorous quality control.

Explore Our Solutions Today:

Standard & Customized Designs

Explosion-Proof Configurations

Remote Monitoring Capabilities

Contact Keepwin Technology Hebei Co., Ltd. to request a quote or schedule a FREE technical consultation!