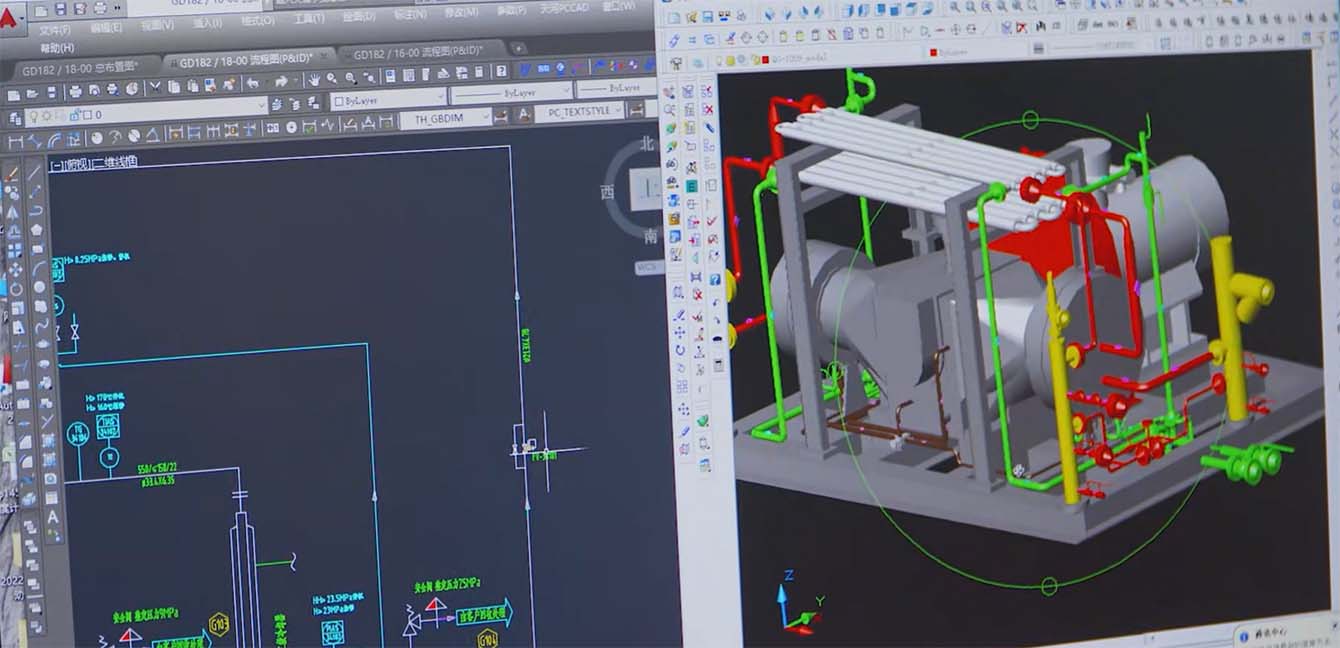

3 Crucial Elements for Designing Process Gas Compressors: A Humorous Guide

Introduction

Ever wondered what goes into designing a process gas compressor? It’s not just about throwing some metal together and calling it a day. Designing a compressor is a delicate dance between pressure, temperature, and flow rate. Think of it as baking a cake – if you get one ingredient wrong, the whole thing can fall flat. In this blog post, we’ll break down the three most important elements to consider when designing a process gas compressor. Buckle up, it’s going to be a wild ride!

- Pressure: The Push and Pull

Imagine a balloon. When you blow into it, you’re increasing the pressure inside. The same goes for a compressor. The pressure you need depends on the specific application. For example, if you’re pumping natural gas through a pipeline, you’ll need much higher pressures than if you’re simply providing air for a pneumatic tool.

Keepwin compressors are designed to handle a wide range of pressures, ensuring that your process runs smoothly and efficiently. Our engineers carefully consider the specific requirements of your application to deliver a customized solution.

- Temperature: Hot or Not?

Temperature is another critical factor in compressor design. As a gas is compressed, its temperature increases. This is why you need cooling systems to prevent overheating. The temperature of the gas can also affect its viscosity and other properties, which can impact the performance of the compressor.

Keepwin compressors are equipped with advanced cooling systems to maintain optimal operating temperatures. Our engineers have a deep understanding of thermodynamics and fluid dynamics, allowing us to design compressors that can handle even the most demanding temperature conditions.

- Flow Rate: The Speed of Things

Flow rate is the volume of gas that passes through a compressor per unit of time. Think of it like a river – the faster the water flows, the wider the river needs to be. In a compressor, the flow rate determines the size of the inlet and outlet ports, as well as the speed of the impeller.

Keepwin offers a wide range of compressors with varying flow rates to meet the needs of different applications. Our engineers can help you select the right compressor to ensure that your process operates at maximum efficiency.

Putting it All Together

Designing a process gas compressor is a complex task that requires careful consideration of pressure, temperature, and flow rate. By understanding these three key elements, you can make informed decisions about the equipment you need.

Keepwin is committed to providing our customers with the highest quality compressors and the best possible service. Our experienced engineers will work with you to design a customized solution that meets your specific needs.

Contact us today to learn more about how Keepwin can help you optimize your process.