5 Little-Known Facts About Reciprocating Compressors

Introduction

Reciprocating compressors, the workhorses of many industries, have been powering countless applications for centuries. While their fundamental principles might seem straightforward, there are numerous intricacies and nuances that set these machines apart. In this article, we will delve into five lesser-known facts about reciprocating compressors, shedding light on the technology that drives these powerful devices.

1. Historical Roots: From Steam Engines to Modern Manufacturing

The history of reciprocating compressors is deeply intertwined with the development of steam engines. Early compressors were essentially modified steam engines, and many of the fundamental design principles have remained unchanged for centuries. In fact, some of the earliest compressors were used in blacksmith shops to power bellows for furnaces. Over time, advancements in materials science and engineering have led to significant improvements in efficiency and reliability, but the basic operating principle of a piston moving back and forth in a cylinder remains the same.

Keepwin has built upon this rich history by incorporating the latest advancements in materials and manufacturing techniques into our reciprocating compressors. Our products combine traditional engineering principles with modern innovations to deliver superior performance and reliability.

2. The Role of Lubrication: More Than Just Oil

Lubrication is critical in reciprocating compressors to reduce friction, wear, and heat. However, the choice of lubricant and the lubrication system can have a significant impact on compressor performance and efficiency. Synthetic lubricants, for example, offer superior thermal stability and oxidation resistance compared to mineral oils, allowing for higher operating temperatures and longer oil change intervals.

Keepwin compressors feature advanced lubrication systems designed to optimize performance and minimize downtime. Our carefully selected lubricants and precision-engineered components ensure that your compressor operates at peak efficiency.

3. The Impact of Piston Rings: A Delicate Balance

Piston rings play a vital role in sealing the compression chamber and preventing blowby. These thin, flexible metal bands are subject to extreme temperatures and pressures, and their design and material selection can significantly affect compressor efficiency and longevity.

Keepwin employs state-of-the-art piston ring technology to ensure optimal sealing and durability. Our piston rings are manufactured from high-quality materials and precision-engineered to minimize wear and extend the life of your compressor.

4. Balancing Efficiency and Capacity: The Role of Clearance Volume

The clearance volume in a reciprocating compressor is the space between the piston and cylinder head at top dead center. While a smaller clearance volume can improve volumetric efficiency, it can also lead to higher discharge temperatures. Engineers must carefully balance these factors to optimize compressor performance.

Keepwin engineers have extensive experience in optimizing clearance volume to achieve the best possible balance of efficiency and capacity. Our compressors are designed to deliver maximum output while minimizing energy consumption.

5. The Importance of Valve Timing: More Than Just Open and Close

The timing of the inlet and outlet valves in a reciprocating compressor has a significant impact on efficiency and performance. Proper valve timing ensures that the compressor fills completely during the intake stroke and discharges the compressed air efficiently.

Keepwin compressors feature precisely engineered valve timing systems that contribute to their exceptional performance. Our advanced control systems ensure optimal valve timing, even under varying load conditions.

Conclusion

Reciprocating compressors are remarkable machines that have evolved significantly over the centuries. By understanding the intricacies of their design and operation, you can make informed decisions when selecting a compressor for your specific application. Keepwin offers a wide range of high-quality reciprocating compressors that are engineered to meet the most demanding requirements. Our commitment to innovation and quality ensures that our products deliver exceptional performance and reliability.

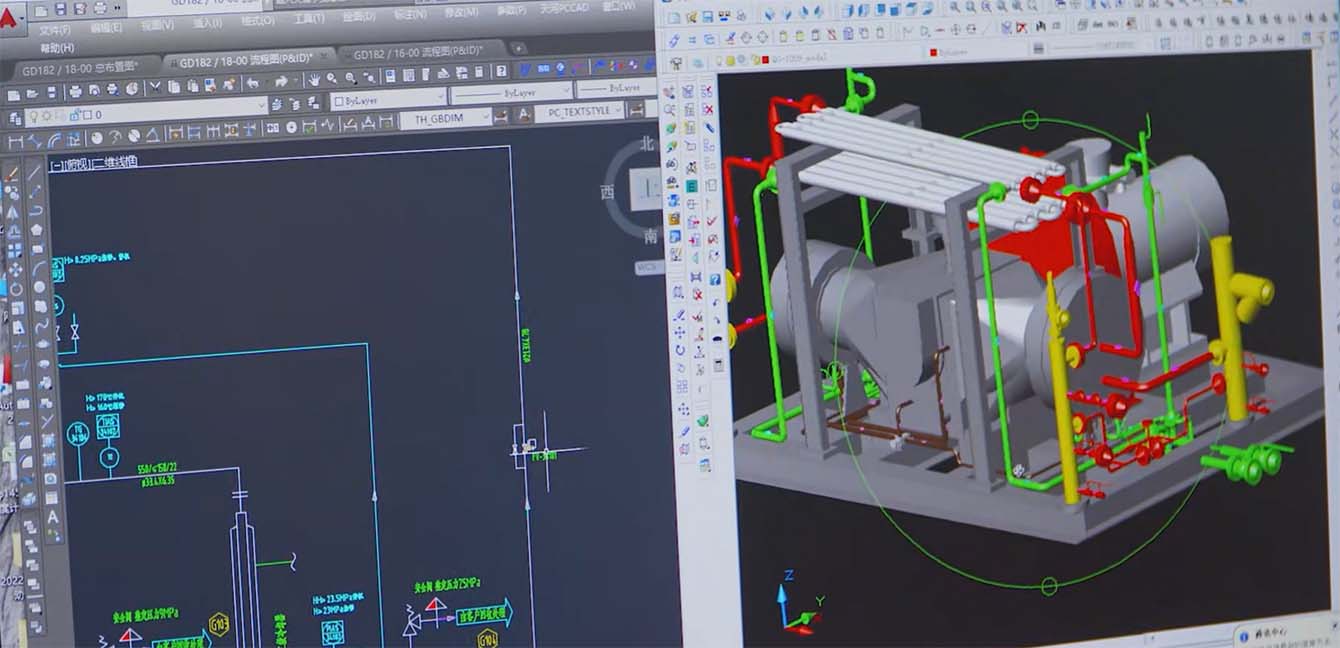

[Insert relevant images or diagrams here to illustrate the points discussed]

Additional topics that could be explored in more detail:

- The impact of operating conditions on compressor performance

- Different types of reciprocating compressor valves

- The role of unloaders in controlling compressor capacity

- Maintenance best practices for reciprocating compressors

Would you like me to add more information or focus on a specific aspect of reciprocating compressors?

2 Responses

您好,这是一条评论。若需要审核、编辑或删除评论,请访问仪表盘的评论界面。评论者头像来自 Gravatar。

Hey this is somewhat of off topic but I was wondering if blogs use WYSIWYG editors or if you have to manually code with HTML. I’m starting a blog soon but have no coding experience so I wanted to get guidance from someone with experience. Any help would be enormously appreciated!